This lease rider form may be used when you are involved in a lease transaction, and have made the decision to utilize the form of Oil and Gas Lease presented to you by the Lessee, and you want to include additional provisions to that Lease form to address specific concerns you may have, or place limitations on the rights granted the Lessee in the standard lease form.

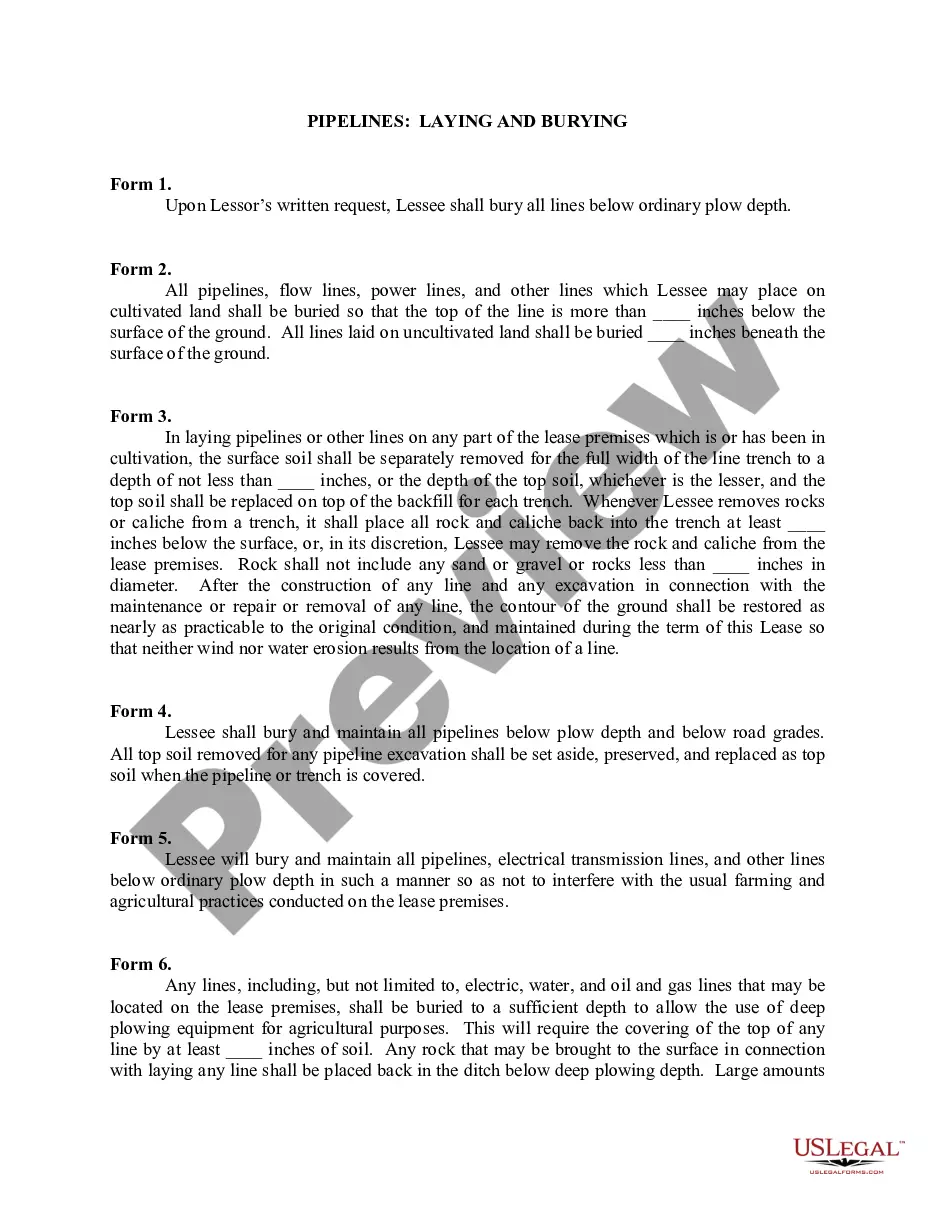

Rhode Island Pipelines - Laying and Burying

Description

How to fill out Pipelines - Laying And Burying?

Finding the right legitimate record template could be a battle. Obviously, there are a lot of layouts accessible on the Internet, but how can you get the legitimate type you need? Use the US Legal Forms site. The service offers a huge number of layouts, such as the Rhode Island Pipelines - Laying and Burying, which you can use for organization and private demands. Every one of the forms are checked out by professionals and meet state and federal specifications.

If you are currently authorized, log in to the profile and then click the Download switch to find the Rhode Island Pipelines - Laying and Burying. Use your profile to check with the legitimate forms you have bought previously. Proceed to the My Forms tab of your own profile and obtain yet another duplicate from the record you need.

If you are a whole new end user of US Legal Forms, here are straightforward recommendations that you should follow:

- Very first, make sure you have selected the proper type for your area/region. It is possible to examine the form while using Preview switch and study the form outline to ensure this is basically the best for you.

- In the event the type is not going to meet your needs, use the Seach industry to find the appropriate type.

- Once you are positive that the form would work, select the Get now switch to find the type.

- Opt for the prices plan you desire and type in the necessary details. Design your profile and pay money for your order using your PayPal profile or bank card.

- Opt for the submit formatting and obtain the legitimate record template to the product.

- Complete, modify and printing and signal the acquired Rhode Island Pipelines - Laying and Burying.

US Legal Forms is the largest catalogue of legitimate forms in which you can discover a variety of record layouts. Use the company to obtain appropriately-created papers that follow condition specifications.

Form popularity

FAQ

Pipeline systems are, in most cases, buried underground. Because they often carry environmentally harmful substances, such as waste or oil, they must be carefully constructed of the materials most appropriate for the substance being transported.

Sending divers to the site is challenging because of the depth of the pipeline: while the known leaks are concentrated in relatively shallow waters?around 50 meters deep?the majority of the pipeline lies 80 to 100 meters underwater.

The depth at which a gas line gets buried varies depending on the country, the town, or the city, but generally should be between 18 and 24 inches deep. Gas pipelines used in commercial areas are typically much deeper than lines used on private property.

Gas pipelines transporting natural gas are typically buried just a few feet below the ground, while those carrying liquefied natural gas may be buried up to 100 feet deeper underground.

While most natural gas pipelines are buried under the ground, there are some that do their work above ground, and these are particularly susceptible to influence and damage from exterior factors.

Pipelines are generally laid underground because temperature is less variable. Because pipelines are usually metal, this helps to reduce the expansion and shrinkage that can occur with weather changes. However, in some cases it is necessary to cross a valley or a river on a pipeline bridge.

Within 36 inches of the outer edge of the pipe (on all sides), only hand excavation, air cutting, vacuum excavation, or potholing techniques are permitted.

Federal regulations require that transmission pipelines and regulated type A gathering lines be buried at least 30 inches below the surface in rural areas and deeper (36 inches) in more populated areas.