South Carolina Maintenance Assistance — Technician Checklist is a comprehensive tool used by maintenance technicians in South Carolina to ensure that all necessary tasks are completed efficiently and effectively. This checklist is designed to outline the steps needed to maintain and repair various types of equipment and systems. It serves as a guideline for technicians to follow in order to achieve optimal performance and reliability. Here are some relevant keywords associated with the South Carolina Maintenance Assistance — Technician Checklist: 1. Preventive maintenance: Including routine checks and inspections to identify and address potential issues before they escalate into major problems. This may involve tasks such as lubrication, cleaning, filter replacement, and adjusting settings. 2. Equipment calibration: Ensuring that instruments and devices are calibrated correctly to maintain accurate readings and measurements. 3. Repairs and troubleshooting: Outlining the steps for identifying and resolving equipment malfunctions or breakdowns. This includes diagnostic procedures, component replacement, and system testing. 4. Safety protocols: Highlighting the importance of following safety guidelines and using proper personal protective equipment (PPE) to minimize risks and accidents in the workplace. 5. Compliance requirements: Addressing any regulatory or industry-specific standards that technicians should adhere to when performing maintenance tasks. Different types of South Carolina Maintenance Assistance — Technician Checklists may exist depending on the specific industry or equipment being maintained. Some examples include: 1. HVAC systems: A checklist specifically tailored for technicians responsible for maintaining heating, ventilation, and air conditioning (HVAC) units. This covers tasks like filter replacement, thermostat calibration, refrigerant level checks, and coil cleaning. 2. Manufacturing equipment: A checklist designed for maintenance technicians working in manufacturing facilities. This may include tasks such as machine lubrication, parts inspection, belt tension adjustment, and preventive maintenance for conveyor systems. 3. Electrical systems: A checklist for electricians or technicians responsible for maintaining electrical equipment. This would cover tasks like checking wiring connections, testing circuit breakers, inspecting grounding systems, and identifying potential hazards. 4. Plumbing systems: A checklist targeted towards technicians responsible for maintaining plumbing systems in residential or commercial buildings. This might include tasks such as checking for leaks, cleaning drains, inspecting water heaters, and fixing plumbing fixtures. In summary, the South Carolina Maintenance Assistance — Technician Checklist is a versatile tool that provides a comprehensive guide for technicians to carry out their maintenance responsibilities effectively. By utilizing this checklist, professionals can ensure that equipment remains in optimal condition, minimizing downtime, and maximizing performance.

South Carolina Maintenance Assistance - Technician Checklist

Description

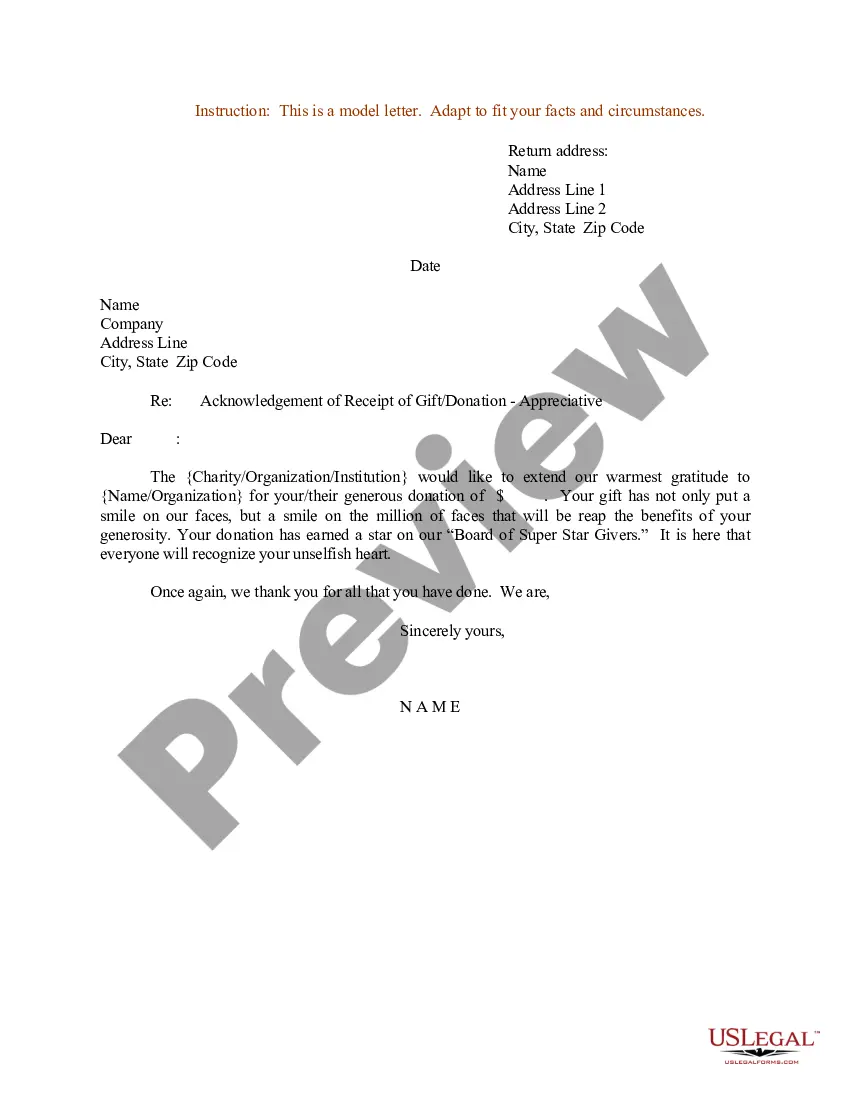

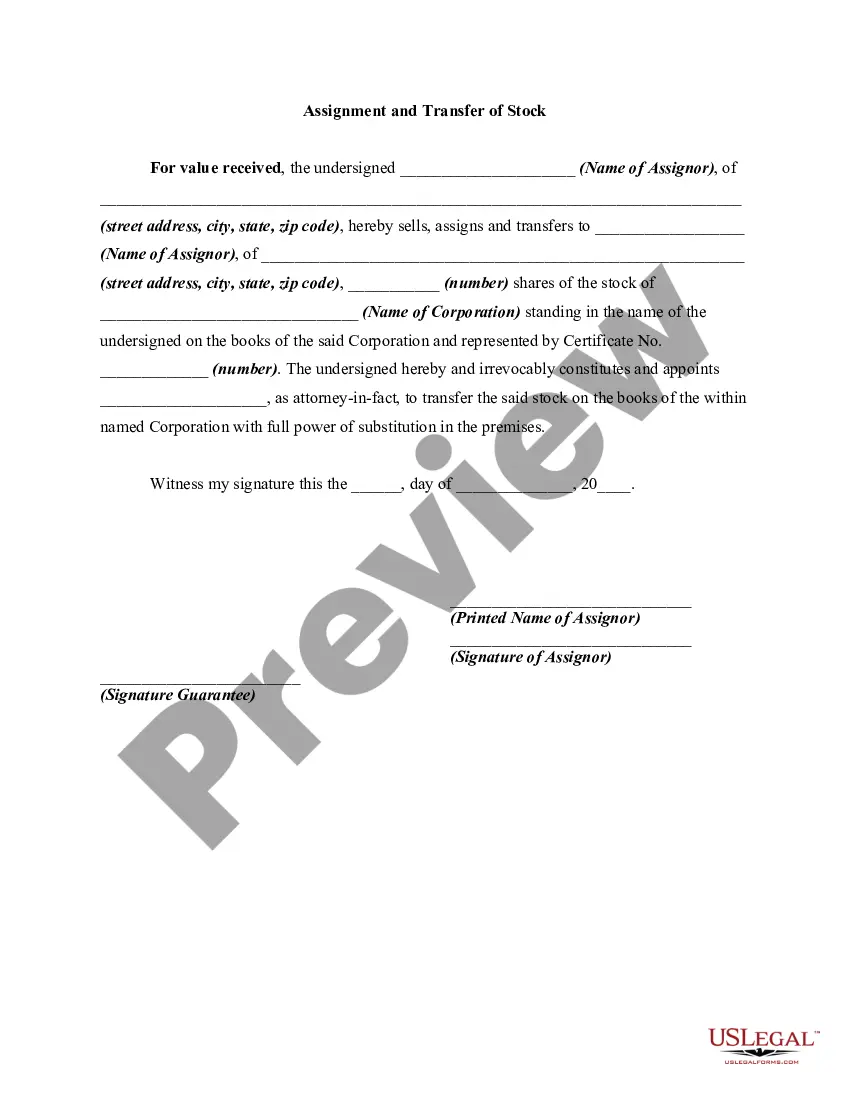

How to fill out Maintenance Assistance - Technician Checklist?

US Legal Forms - one of the greatest libraries of legal forms in the United States - delivers a wide range of legal document themes you are able to obtain or produce. While using site, you may get a large number of forms for enterprise and personal reasons, categorized by categories, states, or key phrases.You can get the latest types of forms like the South Carolina Maintenance Assistance - Technician Checklist within minutes.

If you currently have a registration, log in and obtain South Carolina Maintenance Assistance - Technician Checklist through the US Legal Forms library. The Acquire option will show up on every type you perspective. You have accessibility to all previously saved forms from the My Forms tab of your own accounts.

In order to use US Legal Forms for the first time, listed below are straightforward instructions to help you started off:

- Be sure to have selected the proper type for your personal city/area. Select the Preview option to check the form`s content material. Read the type information to ensure that you have chosen the proper type.

- In case the type does not match your requirements, use the Research industry on top of the display screen to get the one which does.

- In case you are pleased with the shape, confirm your decision by clicking on the Acquire now option. Then, pick the prices plan you favor and offer your references to sign up for the accounts.

- Process the financial transaction. Make use of charge card or PayPal accounts to complete the financial transaction.

- Select the formatting and obtain the shape on the gadget.

- Make alterations. Load, change and produce and indicator the saved South Carolina Maintenance Assistance - Technician Checklist.

Each and every format you included in your bank account does not have an expiration day and is your own for a long time. So, if you want to obtain or produce an additional version, just visit the My Forms segment and then click about the type you require.

Obtain access to the South Carolina Maintenance Assistance - Technician Checklist with US Legal Forms, one of the most considerable library of legal document themes. Use a large number of professional and state-specific themes that meet your small business or personal needs and requirements.

Form popularity

FAQ

Technical knowledge.Attention to details.Organization and task prioritization skills.Ability to see the big picture.Proactiveness.Excellent verbal communication skills.Comfortable working in a team.Ability to work quickly under pressure.More items...?

The average Professional Technician salary is $78,289 per year, or $37.64 per hour, in the United States. People on the lower end of that spectrum, the bottom 10% to be exact, make roughly $59,000 a year, while the top 10% makes $102,000.

4 Essential Skills Any Maintenance Technician Should HaveProblem Solving.Physical Ability.Attention to Detail.Versatility.

There are different types of maintenance skills that can lead to your success within the workplace as a maintenance professional, including:Technical skills.Interpersonal and communication skills.Attention to detail.Problem-solving skills.Administrative and organizational skills.Physical ability.More items...?

How much does a Maintenance technician make in Ireland? The average maintenance technician salary in Ireland is 20ac 45 000 per year or 20ac 23.08 per hour. Entry-level positions start at 20ac 38 533 per year, while most experienced workers make up to 20ac 55 000 per year.

The average salary for a maintenance technician in South Carolina is $44,500 per year.

The Highest Paid Jobs in Mechanical MaintenanceDiesel Mechanics. Diesel mechanics maintain the engines of vehicles that run on diesel fuel, such as buses, 18-wheelers and construction vehicles.HVAC Mechanics.Heavy Equipment Mechanics.Industrial Machinery Mechanics.Aircraft Mechanic salary.

Maintenance and Repair Workers made a median salary of $40,850 in 2020. The best-paid 25 percent made $53,150 that year, while the lowest-paid 25 percent made $32,020.

Maintenance Technician Responsibilities:Inspect buildings, equipment, and systems to identify any issues.Repair faulty equipment units and damaged structures.Develop and implement preventative maintenance procedures.Manage heating and plumbing systems to guarantee functionality.Plan and schedule repairs.More items...