This lease rider form may be used when you are involved in a lease transaction, and have made the decision to utilize the form of Oil and Gas Lease presented to you by the Lessee, and you want to include additional provisions to that Lease form to address specific concerns you may have, or place limitations on the rights granted the Lessee in the standard lease form.

South Carolina Salt Water - Disposal, Storage, and Handling

Description

How to fill out Salt Water - Disposal, Storage, And Handling?

Discovering the right legitimate document format can be quite a battle. Of course, there are a lot of templates accessible on the Internet, but how will you obtain the legitimate develop you need? Take advantage of the US Legal Forms web site. The services offers a large number of templates, for example the South Carolina Salt Water - Disposal, Storage, and Handling, which you can use for business and private requirements. Each of the types are checked by experts and meet federal and state specifications.

When you are presently signed up, log in for your account and click on the Download key to find the South Carolina Salt Water - Disposal, Storage, and Handling. Use your account to check through the legitimate types you might have purchased in the past. Visit the My Forms tab of the account and obtain yet another version of the document you need.

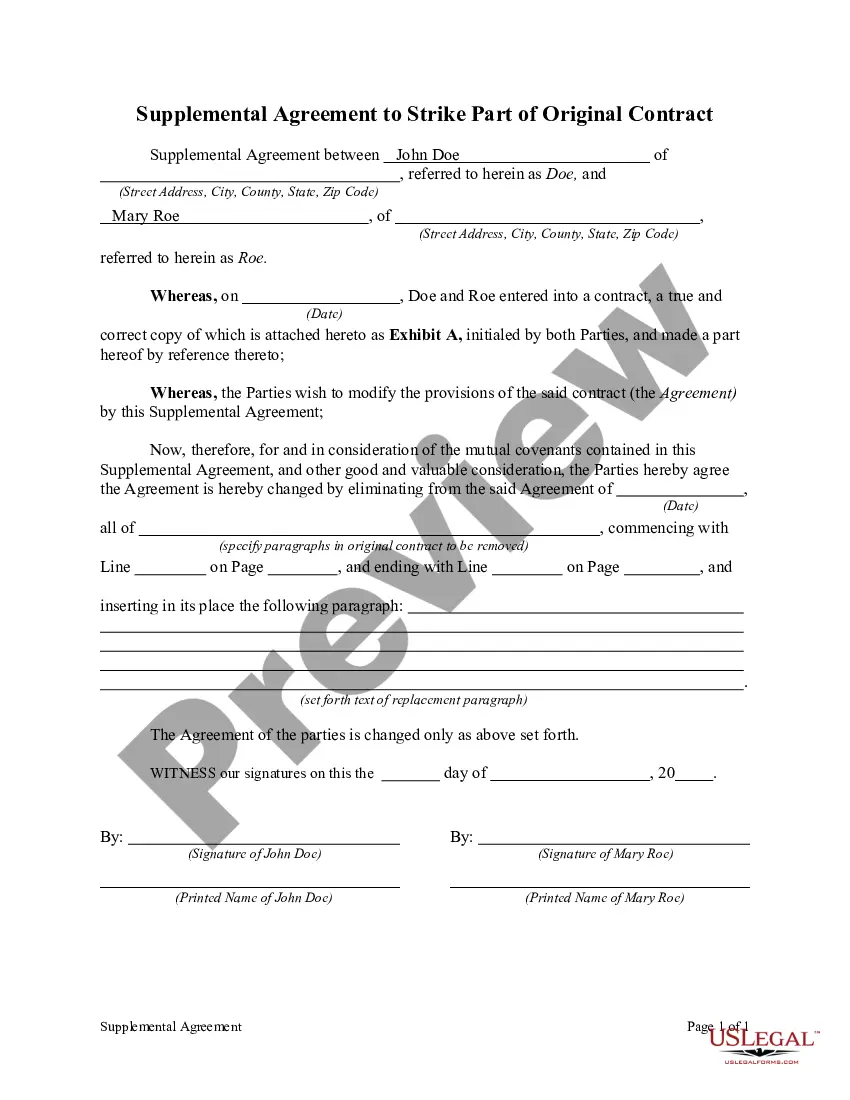

When you are a new customer of US Legal Forms, listed here are basic directions so that you can follow:

- Initial, make sure you have chosen the appropriate develop for your personal area/area. You are able to look through the shape while using Preview key and read the shape information to ensure this is the best for you.

- If the develop does not meet your preferences, utilize the Seach area to get the proper develop.

- Once you are positive that the shape is proper, click on the Buy now key to find the develop.

- Opt for the rates strategy you desire and type in the essential information. Create your account and pay money for your order using your PayPal account or Visa or Mastercard.

- Pick the file format and download the legitimate document format for your device.

- Comprehensive, modify and produce and indicator the received South Carolina Salt Water - Disposal, Storage, and Handling.

US Legal Forms is definitely the greatest local library of legitimate types for which you can see numerous document templates. Take advantage of the service to download appropriately-made papers that follow condition specifications.

Form popularity

FAQ

Call: SCDHEC Emergency Response 24-Hour Toll Free: (888) 481-0125 or (803) 253- 6488 (emergency/24-hours.) South Carolina Law requires reports of spills and releases, which may impact the environment. Do not delay reporting! Calling a local DHEC office DOES NOT COUNT legally as reporting a spill.

All applications must be submitted via regular US Postal mail to the Bureau of Financial Management. Processing time is approximately 12-15 business days.

To find out if your application has been processed, call our office at (803) 896-4426 or access our Verification of S.C. Controlled Substances Registration link to check on the status of your application.

How should infectious waste be packaged and stored? Sharps must be placed in rigid, leak- and puncture-resistant containers secured tightly. All other waste should be stored and maintained in a rigid or semi-rigid leak-proof container.

Horseshoe crab permits, taking and handling requirements; penalty. (A) Taking or possessing horseshoe crabs (Limulus polyphemus) is unlawful except under permit granted by the department.