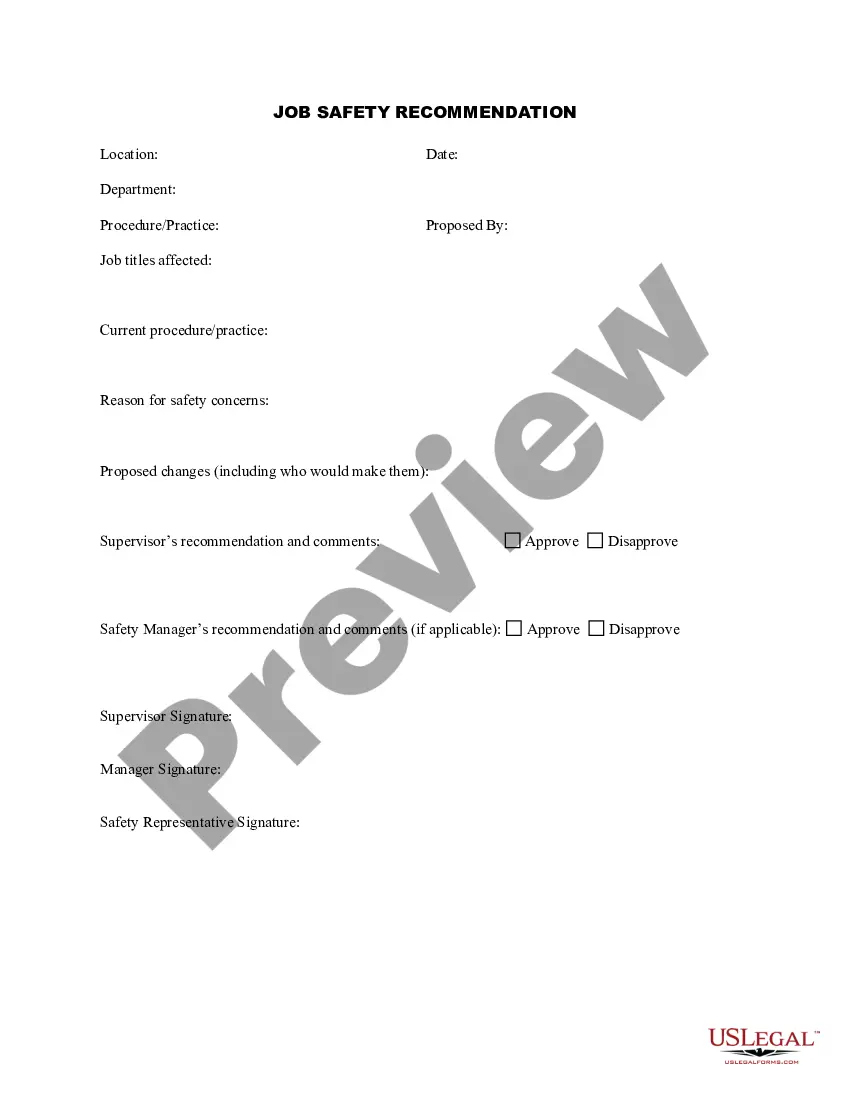

South Dakota Job Safety Recommendation is a comprehensive guideline that aims to ensure a safe working environment for employees across various industries. These recommendations promote the implementation of best practices, training programs, and safety measures to prevent workplace accidents and occupational hazards. By adhering to these recommendations, employers can protect their employees, avoid costly incidents, and maintain a productive workforce. Different types of South Dakota Job Safety Recommendations include: 1. Hazard Communication: Also known as the "Right-to-Know" law, this recommendation focuses on informing employees about the possible hazards associated with the chemicals they handle at work. It includes guidelines regarding proper labeling, safety data sheets, and employee training to ensure the safe handling and storage of hazardous materials. 2. Fall Protection: This recommendation aims to minimize the risk of falls, which are among the leading causes of workplace injuries. It provides guidance on implementing fall protection measures such as guardrails, safety nets, personal fall arrest systems, and proper training for employees working at heights. 3. Electrical Safety: This recommendation focuses on preventing electrical accidents such as electric shocks, electrocution, and fires. It outlines the procedures for using electrical equipment safely, including proper grounding, maintaining insulation, and implementing lockout/ragout procedures to protect workers servicing electrical equipment. 4. Machine Guarding: With the aim of preventing workplace injuries caused by machinery, this recommendation emphasizes the installation of appropriate guards and devices to protect employees from moving parts, flying debris, and other hazardous machine operations. It includes guidelines on regular equipment maintenance, employee training, and safe work practices. 5. Ergonomics: Addressing the well-being of workers in terms of comfort and reduced physical strain, this recommendation focuses on designing workstations and job tasks to minimize the risk of musculoskeletal disorders. It provides guidance on proper posture, adjustable workstations, regular breaks, and employee education. 6. Respiratory Protection: This recommendation aims to safeguard workers from airborne contaminants, such as dust, chemicals, and infectious agents. It includes guidance on the use of respiratory protective equipment, fit testing, training, and proper maintenance to ensure adequate protection. 7. Personal Protective Equipment (PPE): This recommendation outlines the requirement and proper use of personal protective equipment to safeguard employees from different workplace hazards. It covers various types of PPE, including eyewear, gloves, helmets, high-visibility clothing, and respiratory protection, along with emphasizing their correct usage, fit, maintenance, and employer responsibility. It is crucial for employers and employees in South Dakota to familiarize themselves with these recommendations and implement them in their respective workplaces. Regular training, hazard assessments, and continuous improvement efforts contribute to creating a safe and healthy work environment, benefiting both employees and employers.

South Dakota Job Safety Recommendation

Description

How to fill out South Dakota Job Safety Recommendation?

If you have to complete, down load, or print legal record layouts, use US Legal Forms, the largest collection of legal forms, which can be found on the web. Make use of the site`s simple and convenient research to get the files you will need. Different layouts for organization and personal reasons are sorted by types and says, or keywords and phrases. Use US Legal Forms to get the South Dakota Job Safety Recommendation with a couple of click throughs.

In case you are currently a US Legal Forms consumer, log in in your profile and click on the Obtain button to get the South Dakota Job Safety Recommendation. You may also entry forms you formerly acquired inside the My Forms tab of your own profile.

If you use US Legal Forms the first time, follow the instructions listed below:

- Step 1. Make sure you have chosen the shape for that right city/country.

- Step 2. Take advantage of the Review option to look over the form`s articles. Never neglect to read through the information.

- Step 3. In case you are unsatisfied using the type, make use of the Look for field towards the top of the screen to discover other variations in the legal type format.

- Step 4. When you have located the shape you will need, select the Get now button. Pick the rates program you favor and add your references to sign up to have an profile.

- Step 5. Method the deal. You may use your credit card or PayPal profile to perform the deal.

- Step 6. Pick the structure in the legal type and down load it in your system.

- Step 7. Total, edit and print or indication the South Dakota Job Safety Recommendation.

Each and every legal record format you get is yours forever. You may have acces to each type you acquired within your acccount. Click the My Forms portion and select a type to print or down load again.

Contend and down load, and print the South Dakota Job Safety Recommendation with US Legal Forms. There are millions of skilled and express-specific forms you can use for your personal organization or personal demands.