Tennessee Manufacturer Analysis Checklist

Description

How to fill out Manufacturer Analysis Checklist?

Have you ever found yourself needing documents for various business or specific purposes almost every workday.

Numerous legal form templates can be found online, but identifying trustworthy ones can be challenging.

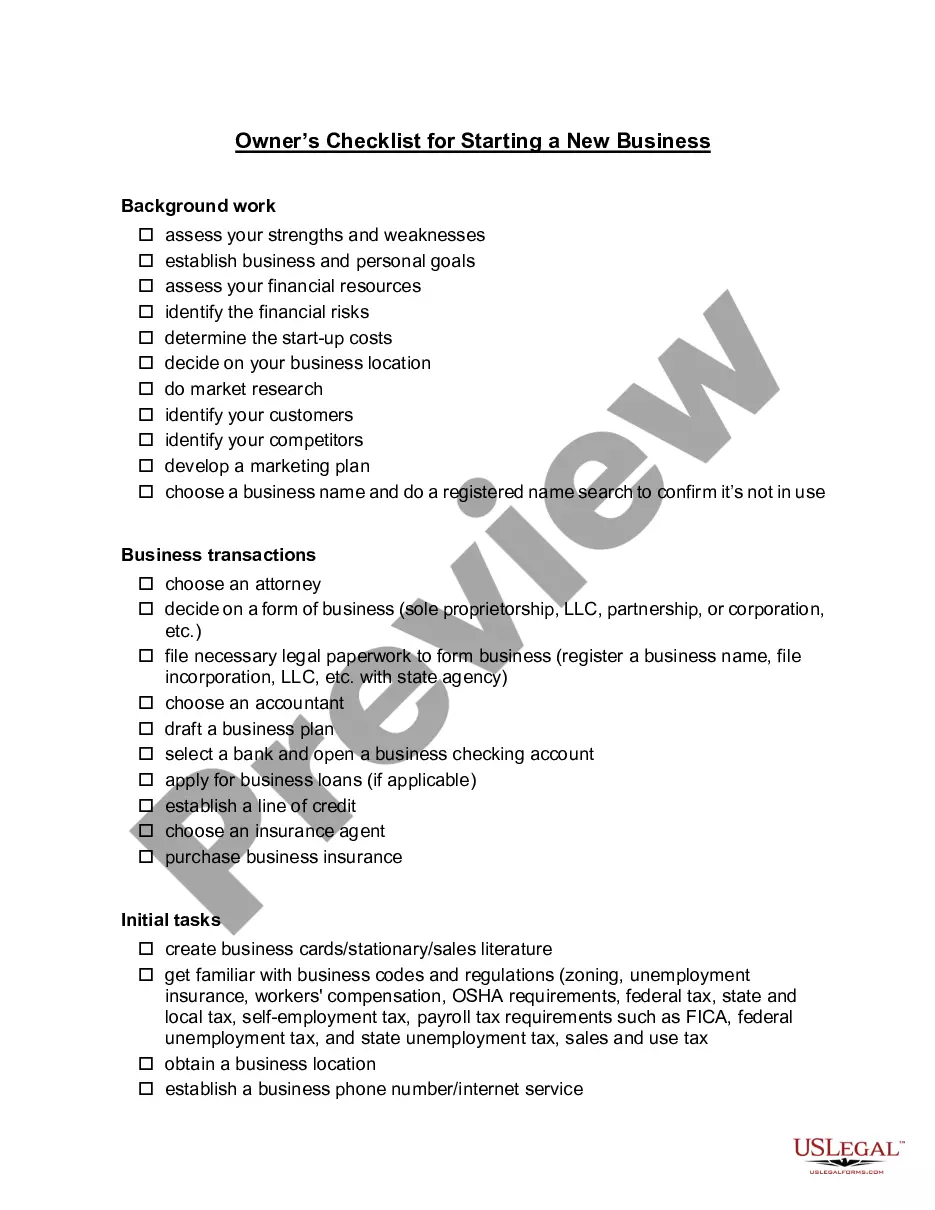

US Legal Forms provides thousands of form templates, including the Tennessee Manufacturer Analysis Checklist, designed to meet federal and state requirements.

Select a preferred file format and download your copy.

Access all the document templates you’ve purchased in the My documents section. You can obtain an additional copy of the Tennessee Manufacturer Analysis Checklist at any time if necessary. Simply click on the desired form to download or print the document template.

- If you are already familiar with the US Legal Forms website and have an account, simply Log In.

- Then, you can download the Tennessee Manufacturer Analysis Checklist template.

- If you do not have an account and wish to start using US Legal Forms, follow these steps.

- Search for the form you need and ensure it is for the correct area/county.

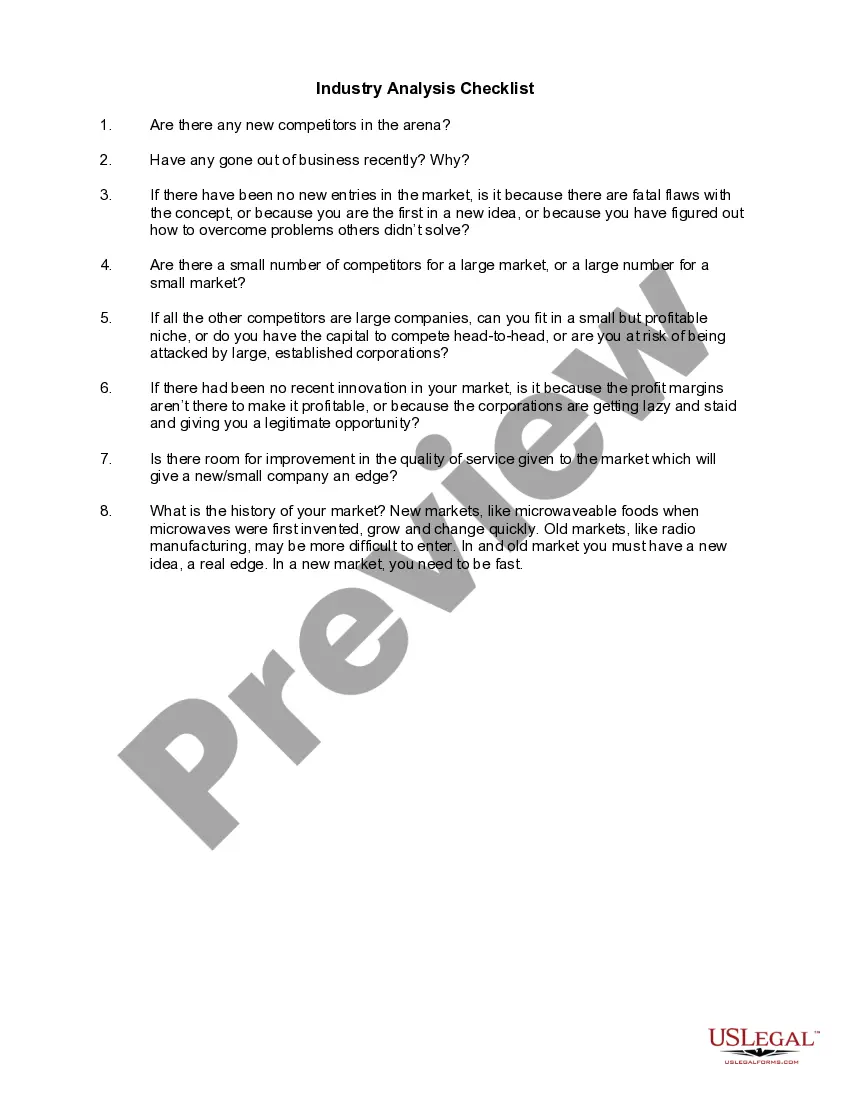

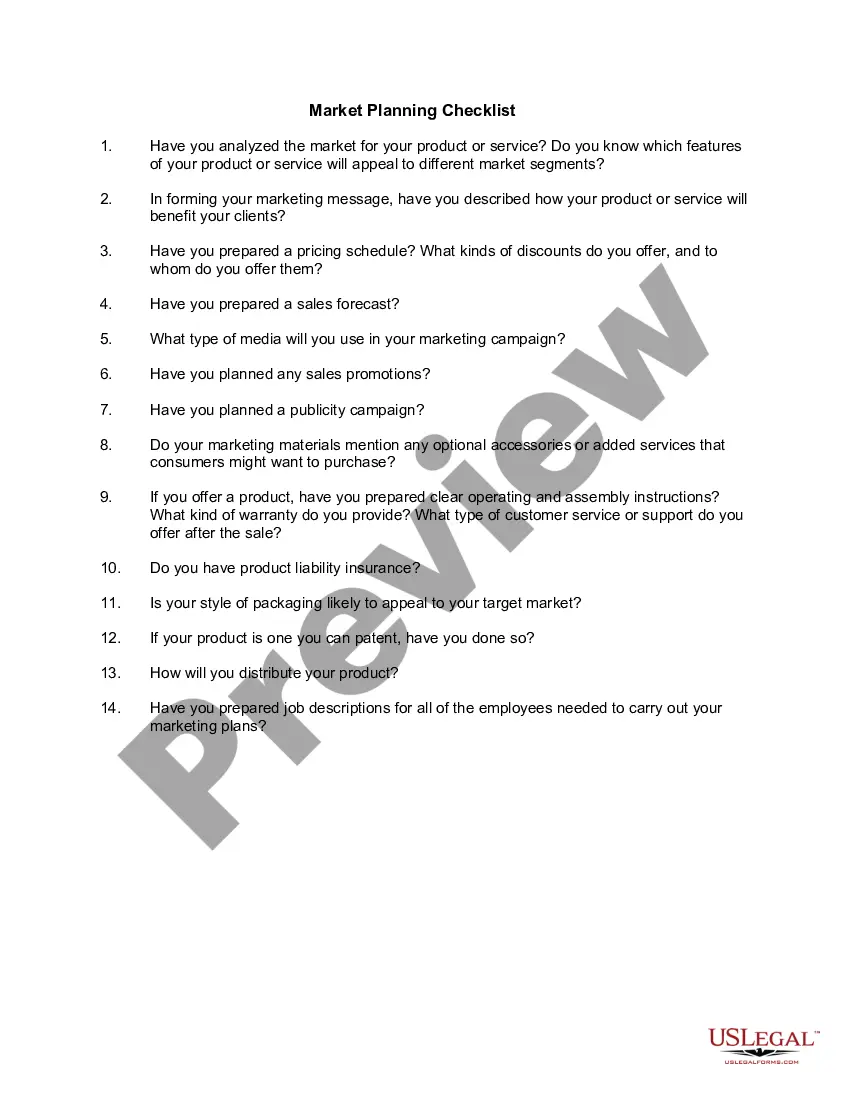

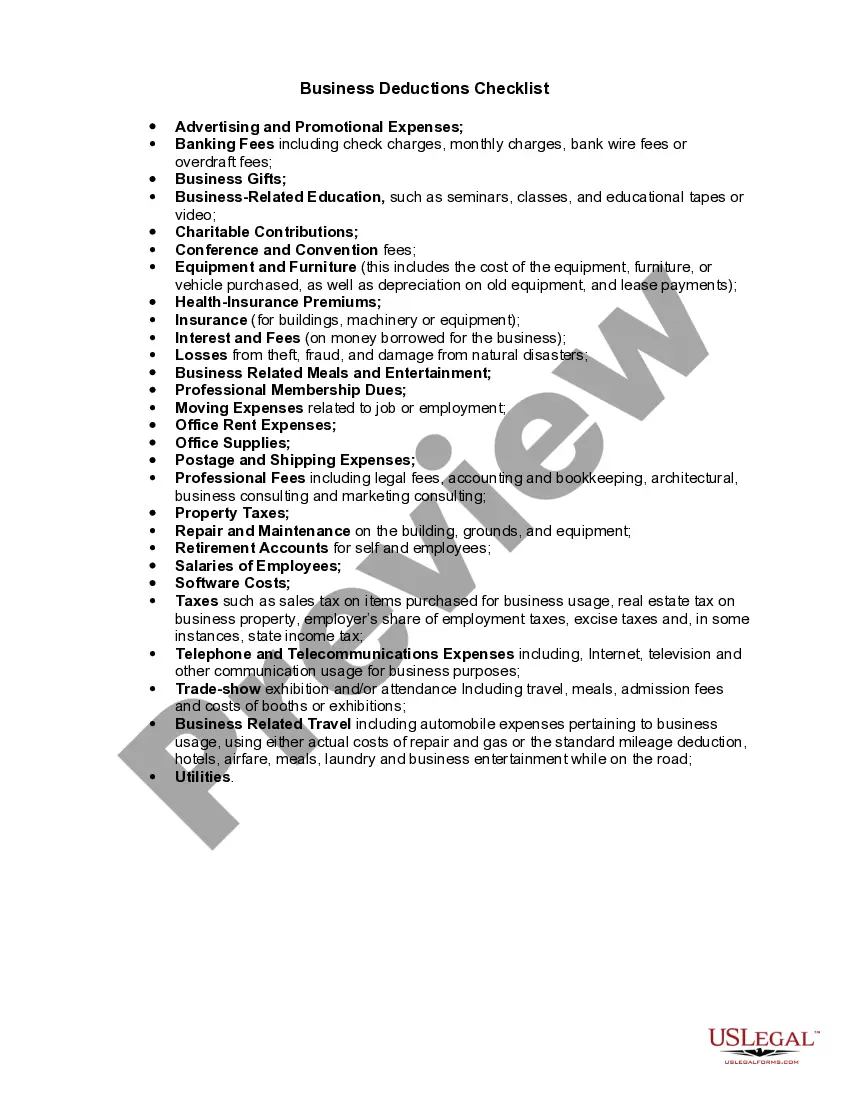

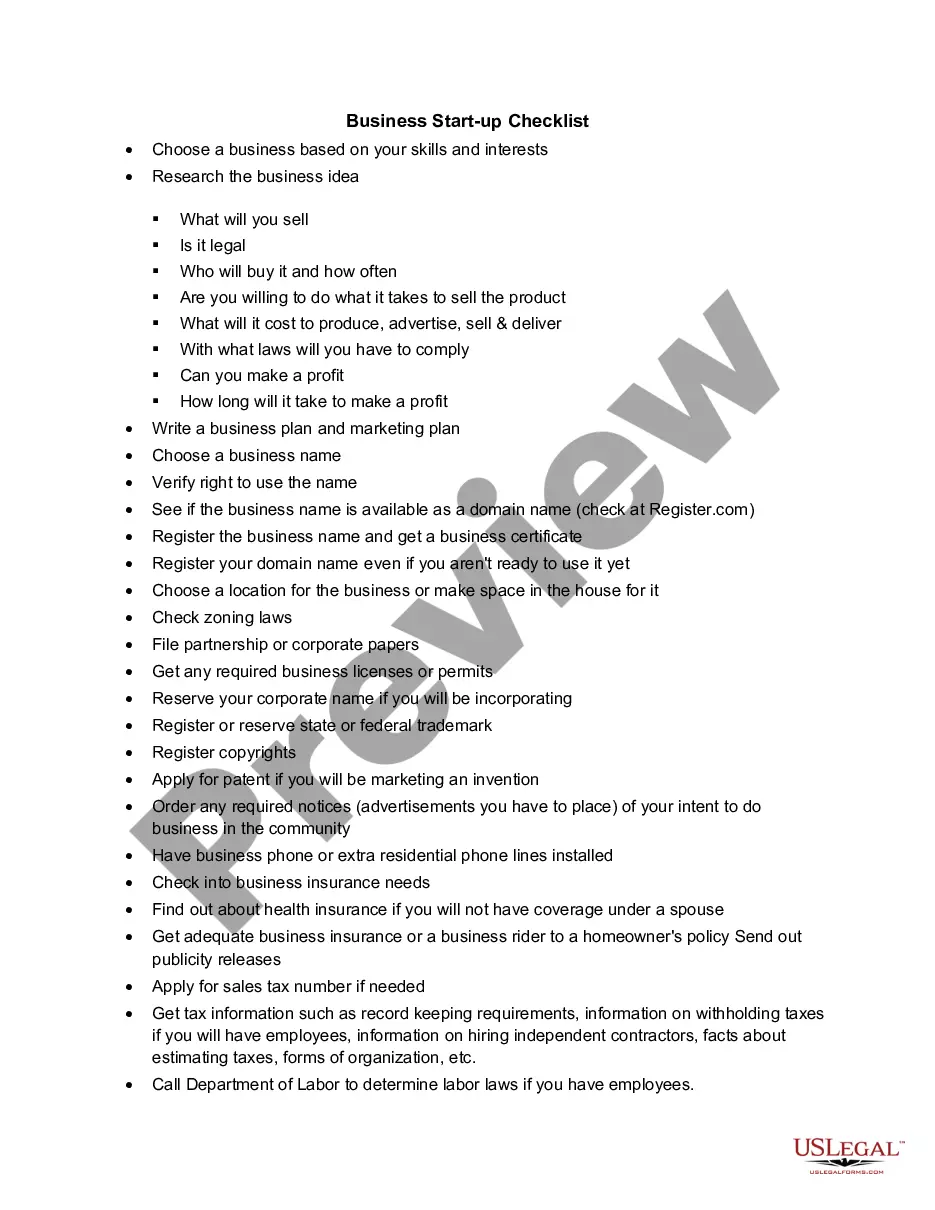

- Use the Review button to check the form.

- Read the description to confirm you have selected the right form.

- If the form is not what you are looking for, utilize the Lookup field to find the form that suits your needs and requirements.

- Once you find the appropriate form, click Buy now.

- Choose the pricing plan you want, complete the required information to create your account, and pay for the order using PayPal or Visa or MasterCard.

Form popularity

FAQ

To file your annual report online in Tennessee, first visit the Secretary of State’s website. You will need to provide specific information about your business for the filing. The online portal is user-friendly, assisting you with any inquiries during the process. Remember to reference the Tennessee Manufacturer Analysis Checklist to ensure you have all the required documents and information ready for a successful submission.

Filing your annual report in Tennessee is a straightforward process. Begin by gathering the necessary information about your business, including its name, address, and officer details. You can easily complete the process online through the state’s official website. Utilizing resources like the Tennessee Manufacturer Analysis Checklist will guide you through the steps, making the filing efficient.

Failing to file your annual report in Tennessee can lead to serious consequences for your business. The state may impose penalties, including late fees and possible dissolution of your company. To avoid these issues, it is vital to stay organized and proactive with your filings. The Tennessee Manufacturer Analysis Checklist can help you ensure compliance and maintain your business's good standing.

The most profitable businesses in Tennessee are often in the manufacturing sector, healthcare, and logistics industries. These fields continue to thrive due to the state’s strategic location and resources. If you are contemplating a manufacturing business, consider using the Tennessee Manufacturer Analysis Checklist to understand market conditions and profitability metrics.

A good business to start in Tennessee often revolves around manufacturing, given the state's strong industrial base. This sector benefits from an established infrastructure and workforce. To maximize your venture's potential, the Tennessee Manufacturer Analysis Checklist can help you assess your business idea and identify key industry characteristics.

A general phone number for Tennessee can be found online, directing you to various governmental departments. Each department has its own specific contact number for more detailed inquiries. Use resources like the Tennessee Manufacturer Analysis Checklist for business-related queries to ensure you connect with the right department.

For inquiries regarding Tennessee taxes, you can contact the Department of Revenue at their direct line. They provide crucial support for both individuals and businesses seeking tax information. Utilizing the Tennessee Manufacturer Analysis Checklist can also help you navigate tax implications specific to manufacturing operations.

The Tennessee woman-owned business certification aims to promote equality and support female entrepreneurs in the state. This certification can enhance visibility and credibility for businesses owned by women. By leveraging resources like the Tennessee Manufacturer Analysis Checklist, women can better understand certifications that may benefit their manufacturing enterprises.

The main contact number for the state of Tennessee varies based on the department you need to reach. Generally, a dedicated phone line for state-related inquiries is available to assist residents and business owners. For specific manufacturer-related questions, consider referring to the Tennessee Manufacturer Analysis Checklist for more streamlined guidance.

Tennessee is the 16th state in the United States, joining the Union on June 1, 1796. This historical significance contributes to its unique culture and business landscape. Utilizing tools like the Tennessee Manufacturer Analysis Checklist can provide insights into how this background may influence your operations.