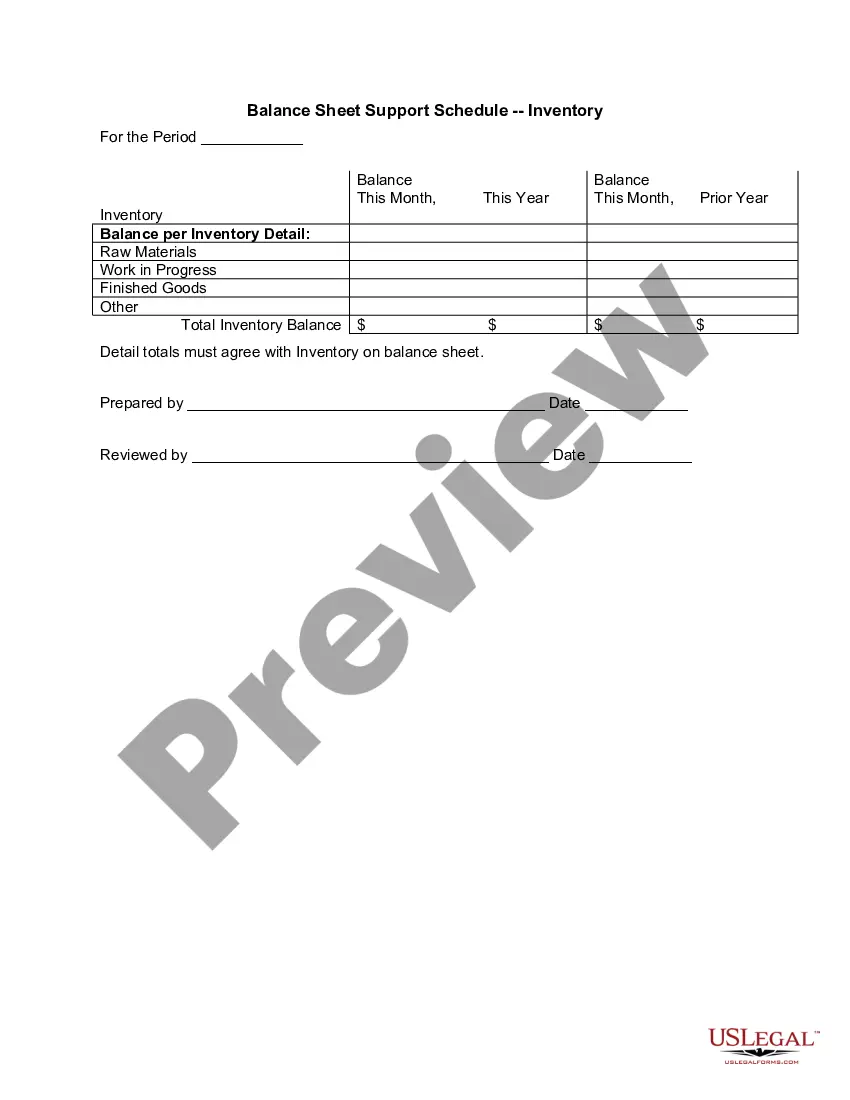

This schedule is tailored for small businesses.

The Tennessee Balance Sheet Support Schedule — Inventory is a crucial financial document that outlines the inventory holdings and its valuation of a business or organization in Tennessee. It provides a comprehensive breakdown of the company's tangible assets, including raw materials, work-in-progress, and finished goods, at a given point in time. This schedule plays a vital role in assessing the financial health and stability of a company and is often used by investors, lenders, and management for decision-making purposes. The Tennessee Balance Sheet Support Schedule — Inventory serves as an essential tool for evaluating the efficiency of inventory management and gauging the overall health of a company's supply chain. It allows businesses to track the cost of inventory accurately, assess the value of goods on hand, and determine the potential obsolescence or spoilage risks associated with their inventory. Moreover, it assists in measuring the company's liquidity and ability to meet its short-term obligations. There are different types of Tennessee Balance Sheet Support Schedule — Inventory, each serving a specific purpose: 1. Raw materials inventory: This category includes the basic materials required to produce goods but have not undergone any processing. It consists of items such as steel, fabric, chemicals, or wood that are yet to be transformed into finished goods. 2. Work-in-progress inventory: Also known as work-in-process (WIP) inventory, this type refers to partially completed goods that are still in the production process. It represents the value of materials, labor, and overhead costs incurred until a specific stage of production. 3. Finished goods inventory: This category encompasses the final products ready for sale. It consists of fully completed and packaged goods that are awaiting distribution to customers or retailers. 4. Merchandise inventory: This type of inventory is specific to retail businesses. It refers to the inventory of goods that are ready for sale to customers, typically bought from suppliers or manufacturers. 5. Consignment inventory: This refers to inventory that is held by one party, referred to as the consignor, and placed with another party, known as the consignee, for sale. The consignee only pays for the inventory once it is sold, while the consignor maintains ownership until then. Properly managing and tracking these various types of inventory is essential for any business to maintain financial stability, optimize production, and satisfy customer demand. The Tennessee Balance Sheet Support Schedule — Inventory acts as a reliable record of the company's inventory position, helping stakeholders make informed decisions to drive growth and profitability.