Tennessee Workplace Safety Rules

Description

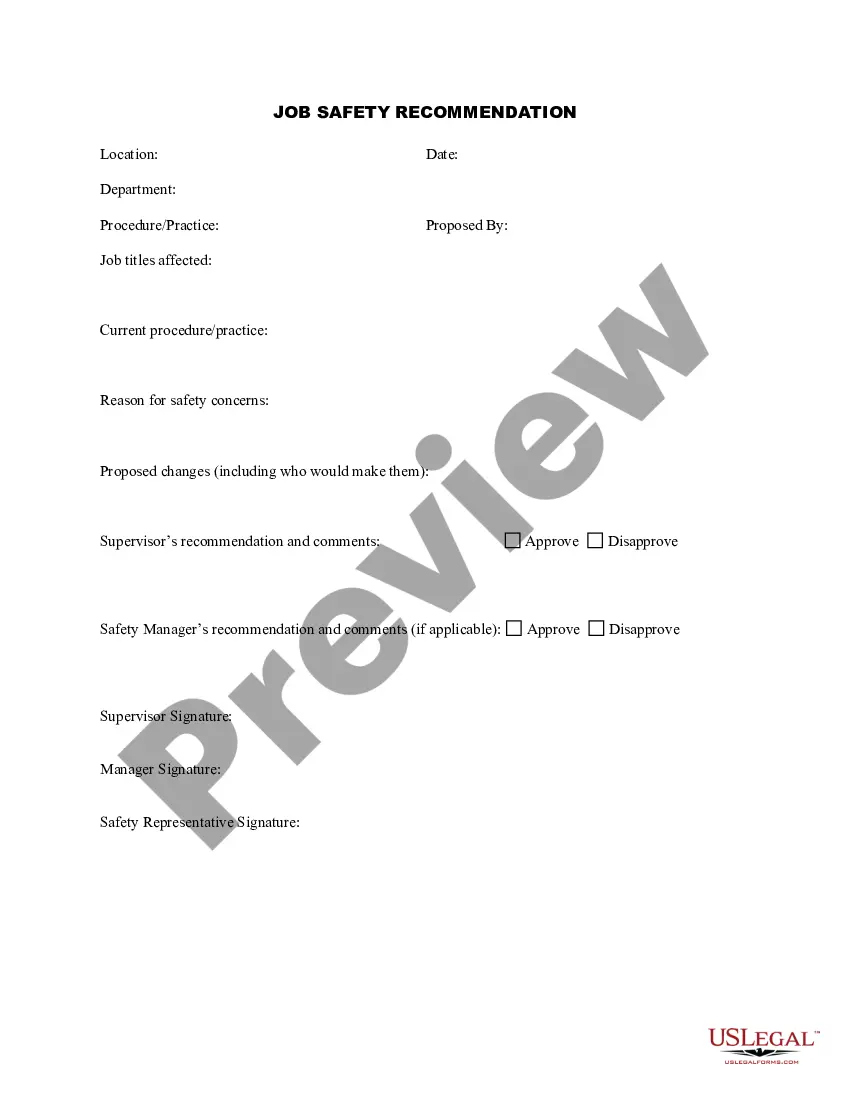

How to fill out Workplace Safety Rules?

Selecting the appropriate legal document format could present a challenge.

Clearly, there are numerous online templates accessible on the web, but how can you find the legal form you need.

Utilize the US Legal Forms website. The service offers a multitude of templates, including the Tennessee Workplace Safety Regulations, suitable for both business and personal uses.

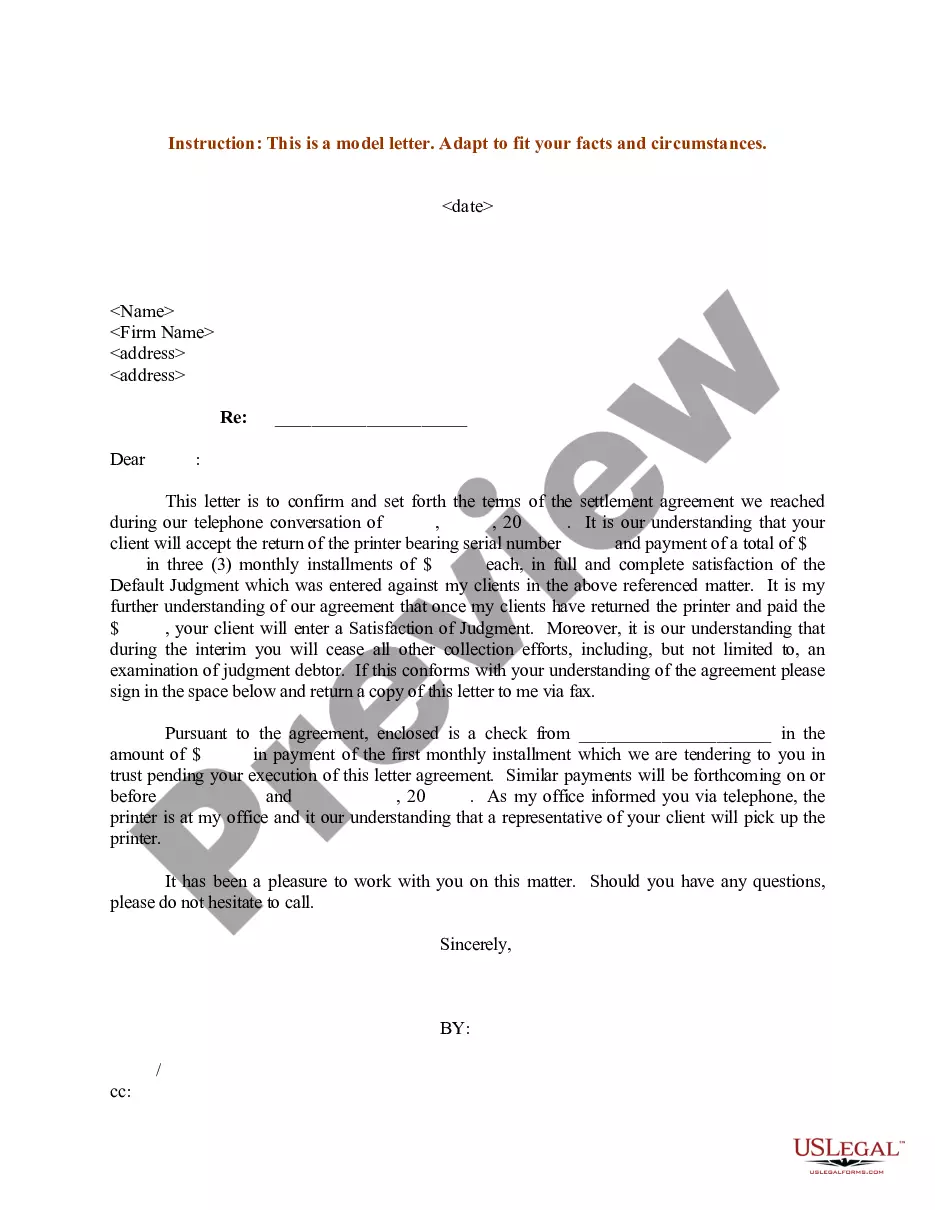

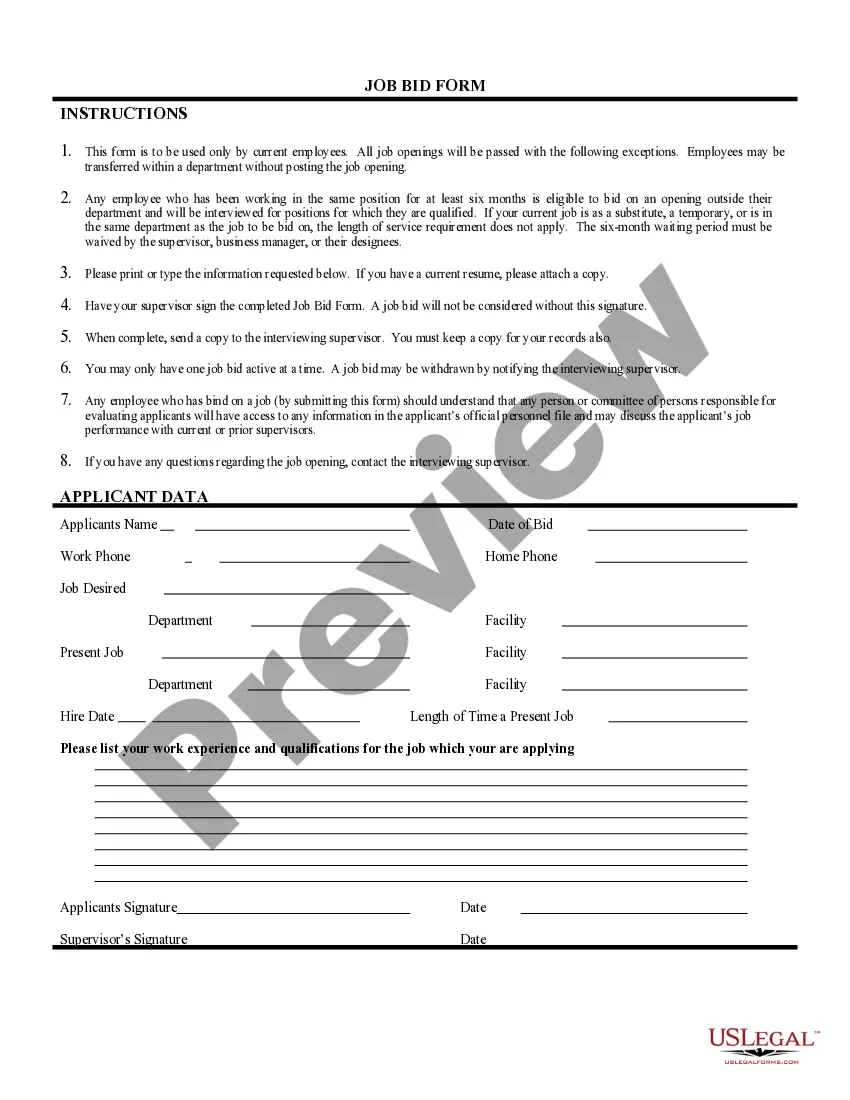

If the form does not meet your needs, use the Search field to find the appropriate form. When you are confident the form is suitable, click the Buy now button to obtain it. Choose the pricing plan you prefer and enter the required details. Create your account and complete the purchase using your PayPal account or credit card. Select the file format and download the legal document template to your device. Fill, edit, print, and sign the acquired Tennessee Workplace Safety Regulations. US Legal Forms is the largest repository of legal forms where you can find a wide variety of document templates. Use the service to download professionally crafted documents that meet state requirements.

- All templates are verified by experts and comply with state and federal regulations.

- If you are already a registered user, sign in to your account and click the Acquire button to obtain the Tennessee Workplace Safety Regulations.

- Use your account to browse the legal forms you have previously purchased.

- Visit the My documents section of your account to retrieve another copy of the document you need.

- If you are a new user of US Legal Forms, follow these straightforward steps.

- First, confirm that you have selected the correct form for your city/region. You can review the document using the Review button and look through the form description to ensure it meets your requirements.

Form popularity

FAQ

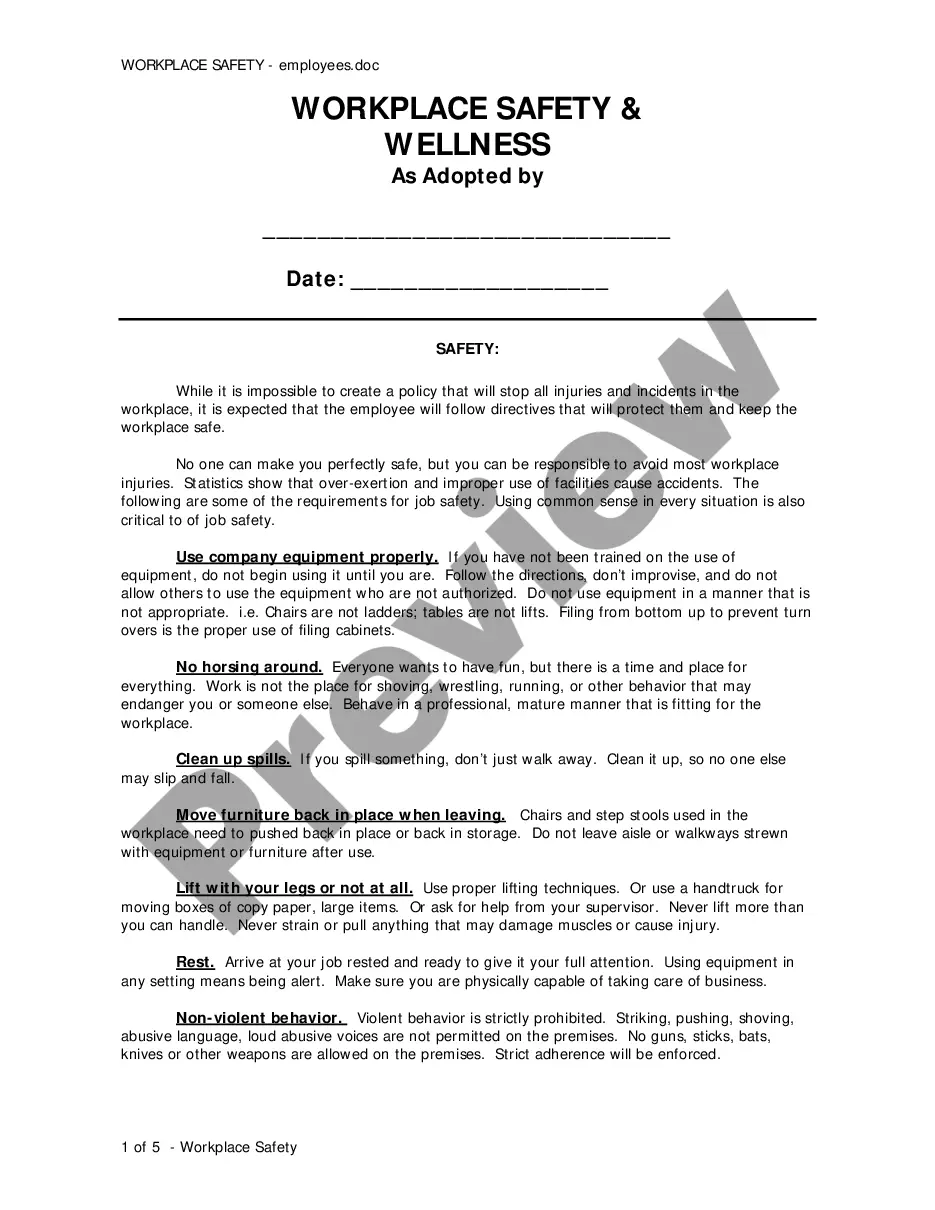

To apply safety in the workplace, begin by educating employees about the importance of following established safety guidelines, such as those outlined in the Tennessee Workplace Safety Rules. Conduct regular safety training sessions, perform safety audits, and encourage team members to voice any safety concerns. By actively engaging in safety practices, companies can create a culture of awareness and prevention.

Plural noun. regulations or rules that are put in place to ensure a product, event, etc, is safe and not dangerous.

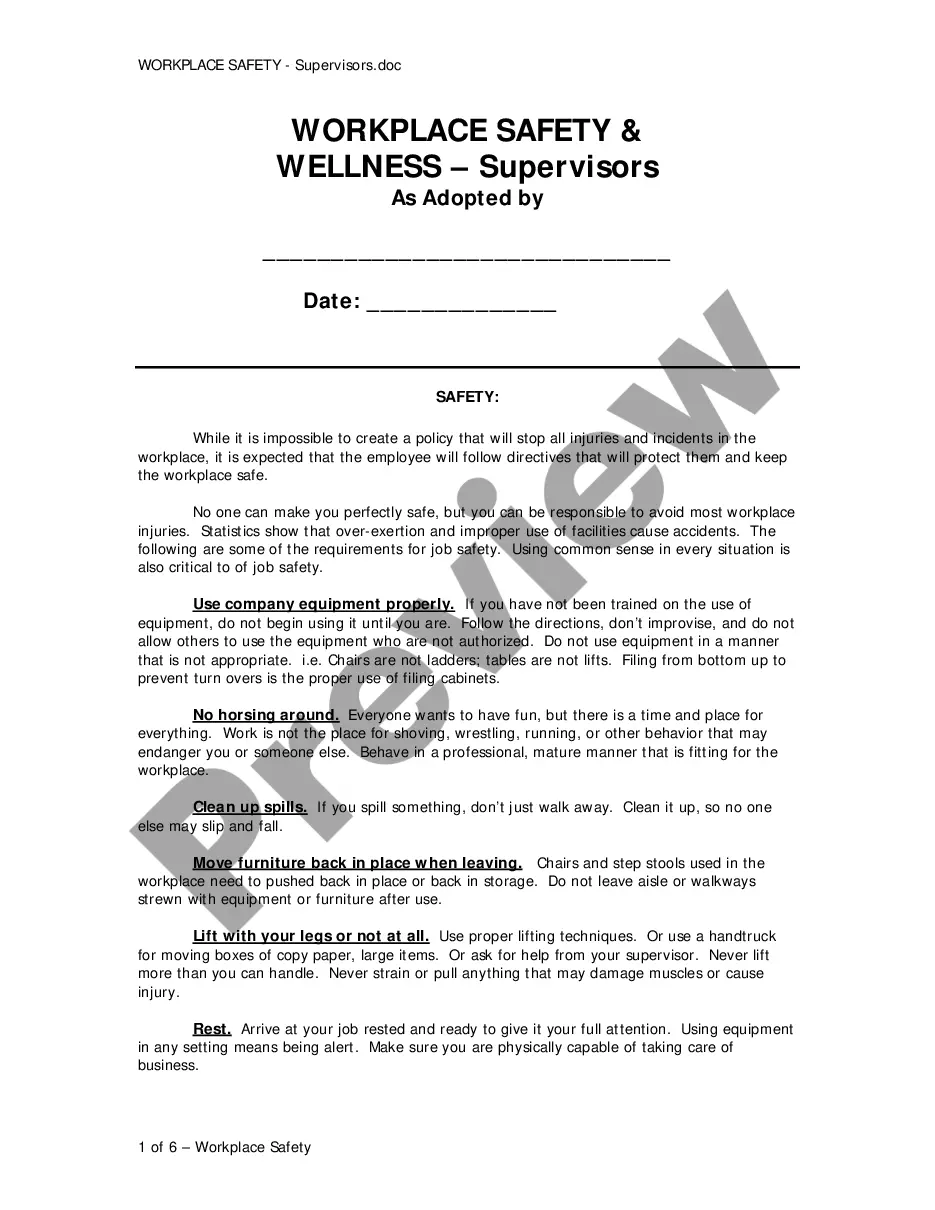

Tennessee OSHA improves occupational safety and health through enforcement of the general industry, construction and agricultural occupational safety and health standards in workplaces.

Region 4 Occupational Safety and Health Administration.

Tennessee is a state-plan state; that is, it has a federally approved occupational safety and health regulatory program.

The following 22 states or territories have OSHA-approved State Plans that cover both private and state and local government workers:Alaska.Arizona.California.Hawaii.Indiana.Iowa.Kentucky.Maryland.More items...

You have the right to a safe workplace. The Occupational Safety and Health Act of 1970 (OSH Act) was passed to prevent workers from being killed or otherwise harmed at work. The law requires employers to provide their employees with working conditions that are free of known dangers.

Most safety regulations in the workplace are enforced by the Occupational Health and Safety Administration, according to the U.S. Department of Labor. Safety regulations are meant to protect workers, while punishing businesses that put their employees in danger.

Tennessee. Tennessee operates an OSHA-approved State Plan covering most private sector workers and all state and local government workers.

Tennessee OSHA (TOSHA) is part of the Tennessee Department of Labor and Workforce Development which is headed by the Commissioner. The central office is located in Nashville. There are also five field offices in Knoxville, Memphis, Chattanooga, Kingsport, and Jackson.