This lease rider form may be used when you are involved in a lease transaction, and have made the decision to utilize the form of Oil and Gas Lease presented to you by the Lessee, and you want to include additional provisions to that Lease form to address specific concerns you may have, or place limitations on the rights granted the Lessee in the “standard” lease form.

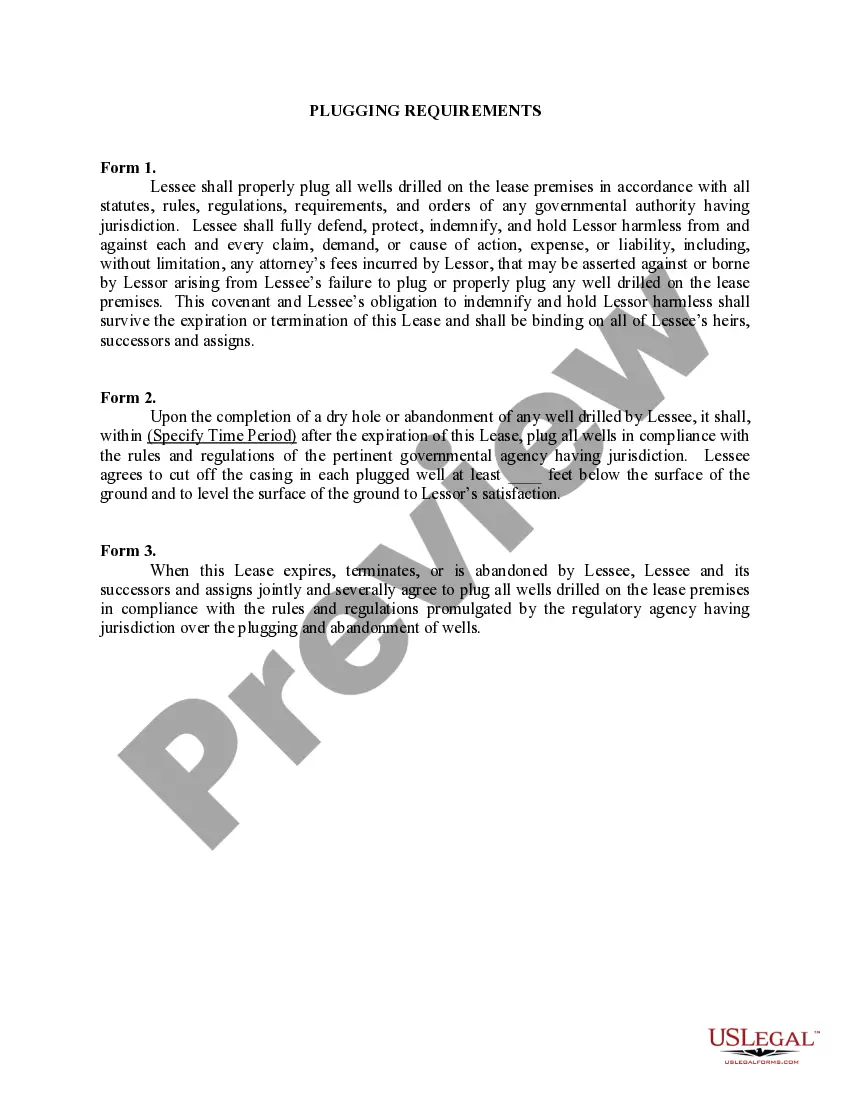

Tennessee Plugging Requirements

Description

How to fill out Plugging Requirements?

Discovering the right legitimate papers template could be a have difficulties. Needless to say, there are a variety of themes available on the net, but how can you obtain the legitimate develop you require? Make use of the US Legal Forms website. The support provides a large number of themes, like the Tennessee Plugging Requirements, which can be used for company and private needs. Each of the kinds are checked out by specialists and satisfy federal and state demands.

If you are already authorized, log in for your bank account and click the Acquire key to get the Tennessee Plugging Requirements. Use your bank account to check with the legitimate kinds you have bought formerly. Check out the My Forms tab of your respective bank account and get an additional copy of your papers you require.

If you are a whole new customer of US Legal Forms, listed below are basic instructions that you can adhere to:

- Very first, be sure you have chosen the right develop to your city/county. You can examine the form while using Preview key and study the form information to guarantee it is the right one for you.

- When the develop does not satisfy your expectations, make use of the Seach industry to obtain the proper develop.

- When you are certain that the form is proper, select the Acquire now key to get the develop.

- Pick the prices prepare you need and enter in the essential information and facts. Build your bank account and pay money for the transaction using your PayPal bank account or Visa or Mastercard.

- Pick the file format and down load the legitimate papers template for your device.

- Comprehensive, change and printing and signal the obtained Tennessee Plugging Requirements.

US Legal Forms is the greatest library of legitimate kinds in which you will find different papers themes. Make use of the company to down load expertly-produced documents that adhere to express demands.

Form popularity

FAQ

05 PERMITS. (a) Any person may perform electrical work (for which an inspection is required) upon his/her own residence provided he/she first applies for and obtains a residential property owner's electrical permit. This permit shall only extend to the applicant and the immediate members of the applicant's family.

An oil or gas well is plugged and abandoned when it reaches the end of its useful life or becomes a dry hole. These operations include activities and tasks that present hazards to workers.

A natural gas well isn't at all like a water well (where you drill a hole in the ground and water fills it). Natural gas tends to be contained within the underground rock itself. The rock must be broken to release the gas. And if it's brought out the wrong way, it can contaminate the groundwater supply surrounding it.

Fracking is a temporary process that occurs after a well has been drilled and usually takes only about 3-5 days per well. Sometimes, wells are re-fracked to extend their production, but the energy each well can produce may last for 20 to 40 years.

The vast majority of drilling operations in Tennessee are standard vertical tests drilled with air rotary equipment that vary in depth from 2,000 feet to 6,000 feet.