A Strategy for Research and Development

Research and development (R & D) needs to be carefully planned and managed to succeed. It is easy to waste money on developing ideas that go nowhere, but getting it right can lead to business stability, security and long-term profits.

Planning

R & D should be included in your overall business plan. The plan should illustrate the direction you want the business to take and how R & D fits in with your other business activities. Set out clear objectives, time frames and budgets. A clear plan can prevent the project straying from your business goals and wasting valuable resources and money.

You may need to involve staff with specific skills to draw up the plan, for example finance staff to set up budgets. You may also need outside help.

Your plan should set out the steps that need to be taken from the inception of the ideas to the product launch. You should allocate the necessary resources to the project, including funding, staff and time. You might decide to set up a specific team to work on the project.

Management

Good management is vital to reduce risk of failure and realize as many ideas as possible.

To manage R & D projects effectively you should:

" Make sure staff involved in R & D understand the business' overall strategy;

" Ensure these employees understand what is commercially realistic;

" Assess the changing risks and potential of projects as they progress, continually developing a rigorous business case;

" Ensure that intellectual property ownership issues are resolved;

" Recognize when a project isn't going to work; and

" Understand the relative importance of different projects to your business.

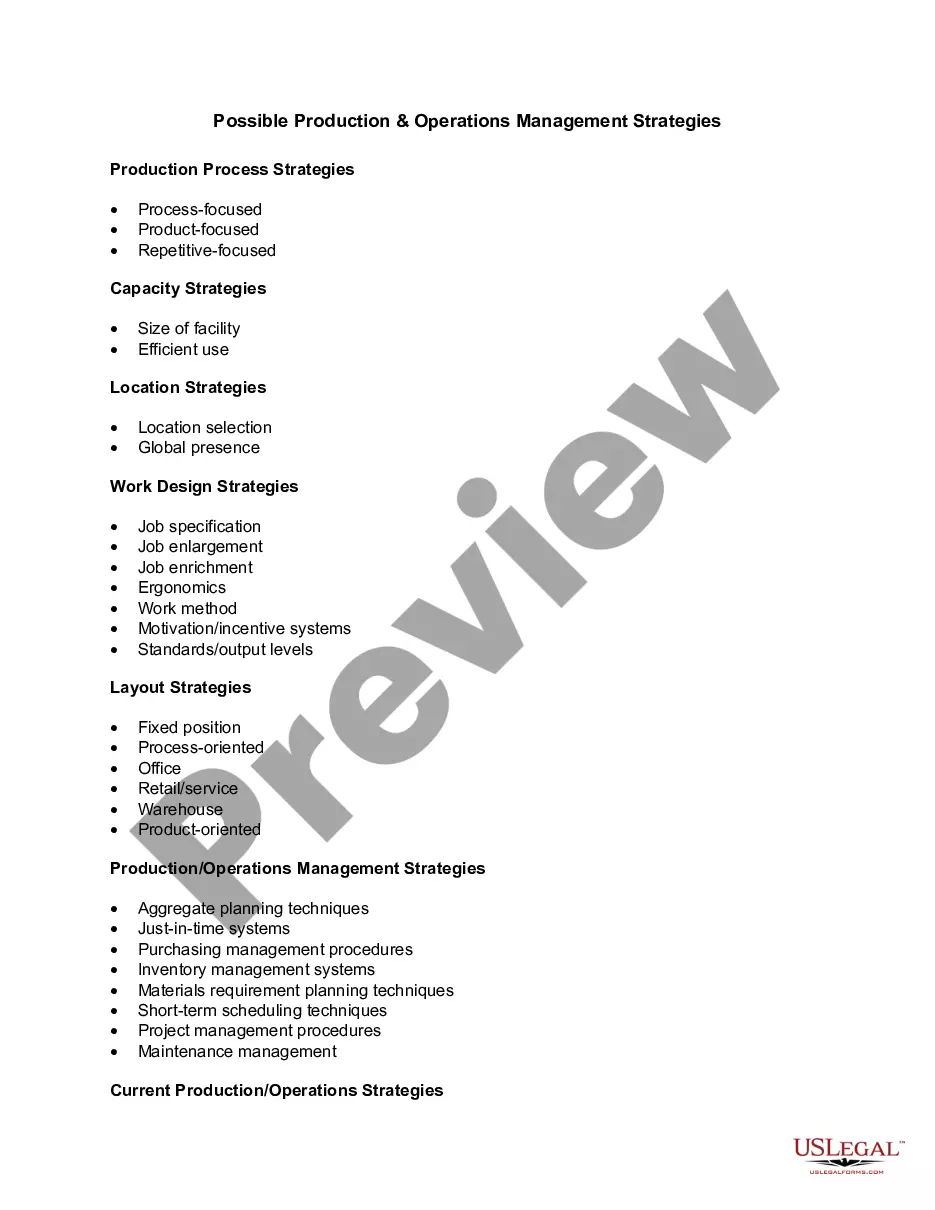

Texas Possible Production and Operations Management Strategies are the various approaches and techniques implemented by businesses operating in the state of Texas to streamline their production and operational processes. These strategies aim to enhance efficiency, reduce costs, improve customer satisfaction, and ultimately drive business growth. Key operational keywords: production, operations management, strategies, efficiency, cost reduction, customer satisfaction, growth, Texas 1. Lean Manufacturing Strategy: One of the most widely used strategies in Texas is lean manufacturing. It focuses on eliminating non-value-added activities and waste from the production process. By implementing lean principles such as just-in-time inventory management and continuous improvement, companies enhance efficiency and reduce costs. 2. Six Sigma: Texas-based companies also embrace Six Sigma, a data-driven methodology aimed at minimizing defects and variation in manufacturing and operational processes. By employing statistical analysis and process improvements, businesses in Texas can optimize quality and reduce operational inefficiencies. 3. Total Quality Management (TQM): TQM is another crucial strategy adopted by businesses in Texas. It emphasizes continuous improvement, customer satisfaction, and employee involvement. Organizations incorporate TQM principles like quality control, quality assurance, and quality improvement to enhance operational processes and customer experiences. 4. Supply Chain Management: Texas businesses also focus on effective supply chain management strategies. By integrating suppliers, manufacturers, and distributors, companies achieve seamless coordination and collaboration, reducing lead times, minimizing stock outs, and optimizing overall supply chain performance. 5. Strategic Capacity Planning: To anticipate future demands, Texas companies implement strategic capacity planning strategies. By analyzing market trends and forecasting demand, they ensure their production and operational capacities align with expected requirements. This allows companies to avoid costly underutilization or bottlenecks and maintain a competitive edge. 6. Agile Manufacturing: In order to swiftly respond to changing market demands, Texas businesses adopt agile manufacturing strategies. Agile manufacturing focuses on flexibility and adaptability, allowing companies to quickly adjust production processes, incorporate customer feedback, and rapidly bring new products to the market. 7. Technology Integration: Texan companies are also leveraging technology integration strategies to optimize production and operational processes. Innovations like automation, artificial intelligence, Internet of Things (IoT), and cloud computing help businesses streamline operations, enhance efficiency, and reduce costs. 8. Continuous Improvement: Continuous improvement is a fundamental mindset adopted by Texas companies. By encouraging employees to identify inefficiencies and suggest improvements, organizations foster a culture of innovation and a commitment to ongoing optimization of production and operational processes. Overall, Texas Possible Production and Operations Management Strategies encompass a range of techniques and philosophies aimed at enhancing efficiency, reducing costs, and driving business growth. Whether through lean manufacturing, Six Sigma, TQM, supply chain management, capacity planning, agile manufacturing, technology integration, or continuous improvement, Texan businesses are committed to delivering exceptional products and services to their customers.