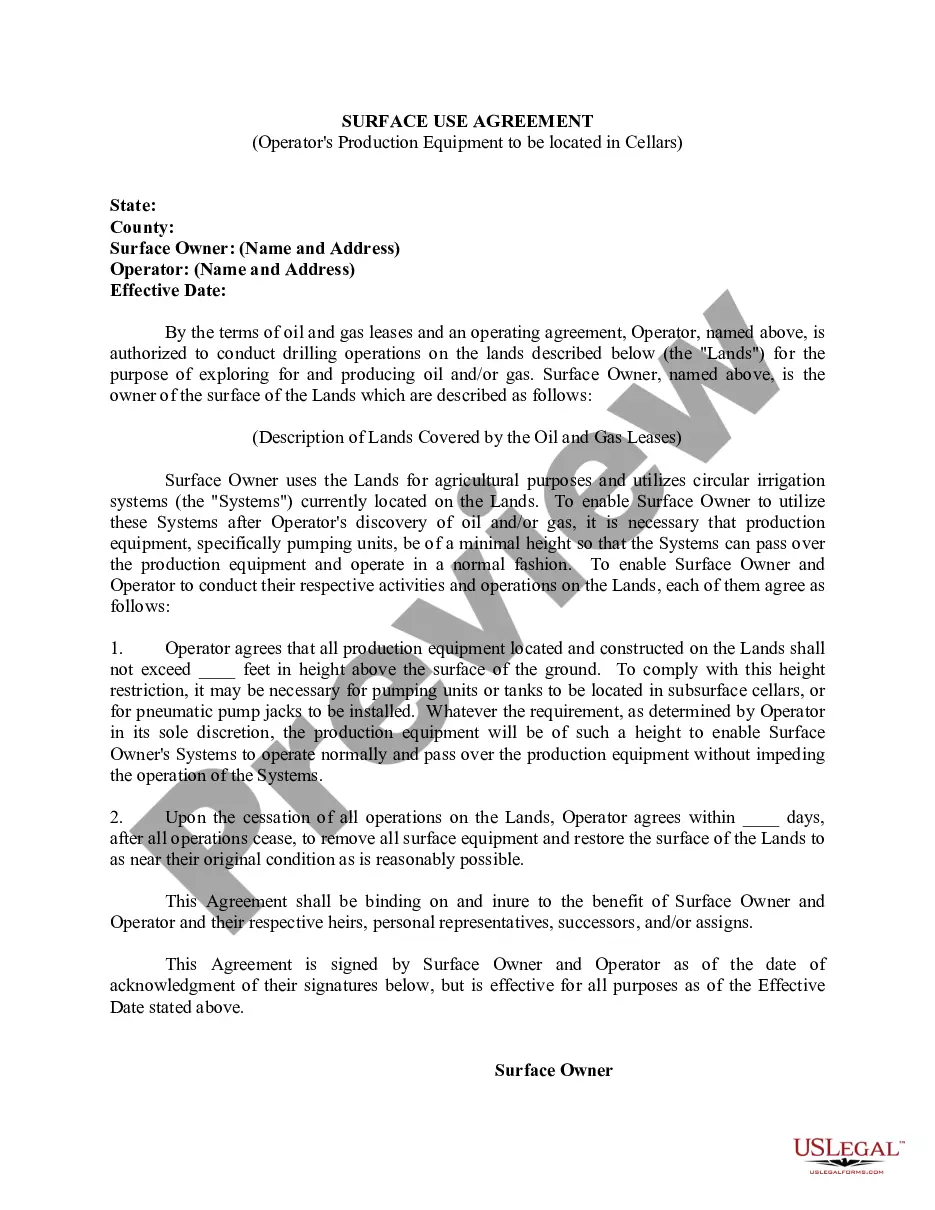

Texas Surface Use Agreement when Operator's Production Equipment to Be Located in Cellars

Description

How to fill out Surface Use Agreement When Operator's Production Equipment To Be Located In Cellars?

Are you in the place where you need to have papers for sometimes organization or personal uses almost every time? There are plenty of legal document web templates accessible on the Internet, but locating kinds you can trust is not simple. US Legal Forms provides 1000s of develop web templates, like the Texas Surface Use Agreement when Operator's Production Equipment to Be Located in Cellars, that happen to be published to satisfy state and federal needs.

When you are presently acquainted with US Legal Forms site and have a free account, merely log in. After that, you can obtain the Texas Surface Use Agreement when Operator's Production Equipment to Be Located in Cellars template.

Unless you offer an profile and wish to begin to use US Legal Forms, follow these steps:

- Get the develop you require and ensure it is for the proper area/region.

- Use the Preview key to check the form.

- See the explanation to ensure that you have selected the proper develop.

- When the develop is not what you`re looking for, use the Research industry to get the develop that suits you and needs.

- When you find the proper develop, just click Purchase now.

- Select the costs program you desire, fill out the desired information to make your money, and purchase the order utilizing your PayPal or bank card.

- Decide on a practical data file structure and obtain your version.

Discover all of the document web templates you may have bought in the My Forms menus. You can get a further version of Texas Surface Use Agreement when Operator's Production Equipment to Be Located in Cellars whenever, if needed. Just click on the essential develop to obtain or print out the document template.

Use US Legal Forms, the most extensive selection of legal varieties, to conserve some time and stay away from mistakes. The services provides professionally manufactured legal document web templates that can be used for a variety of uses. Make a free account on US Legal Forms and initiate making your daily life easier.

Form popularity

FAQ

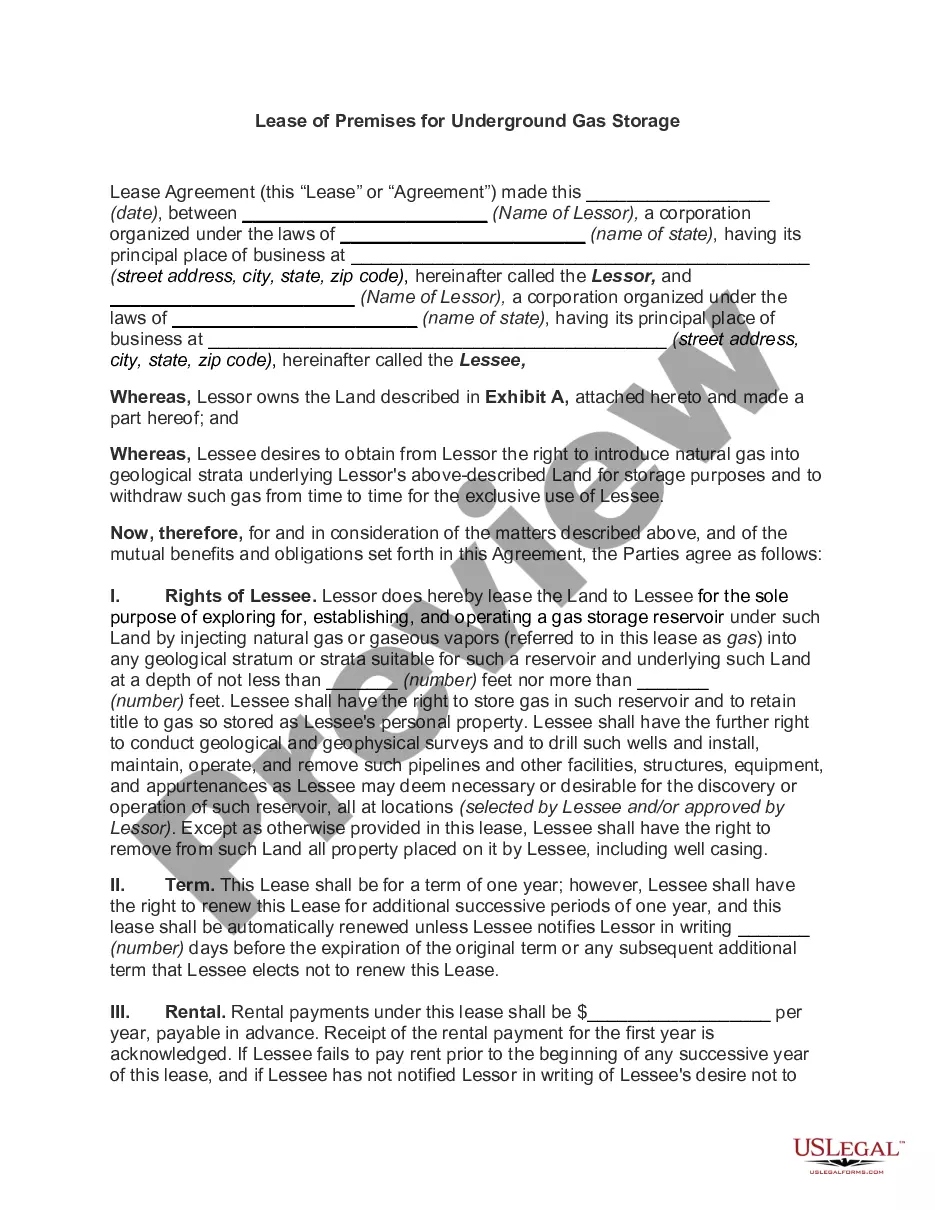

A surface use agreement, which is also sometimes referred to as a land use agreement, is an agreement between the landowner and an oil and gas company or an operator for the use of the landowner's land in the development of the oil and gas.

Concerning land ownership and property law, subsurface rights can allow a property owner to discover and utilize anything extracted from underneath a property without interference from a second party. Purchasing both rights for a property is possible.

Subsurface rights usually include the right to oil, minerals and even water that's found beneath the land's surface.

Subsurface means in a well, or below the surface of the ground. Seismic surveys are used to find subsurface rock structures that may contain hydrocarbons. Directional wells can be used to drill multiple wells from a common drilling pad or to reach a subsurface location beneath land where drilling cannot be done.

A surface use agreement, which is also sometimes referred to as a land use agreement, is an agreement between the landowner and an oil and gas company or an operator for the use of the landowner's land in the development of the oil and gas.

Subsurface rights means the rights to all minerals, mineral fuels, and other resources, including, but not limited to, oil, gas, coal, oil shale, uranium, metals, and phosphate, whether or not they are mixed with any other substance found or located beneath the surface of the earth.