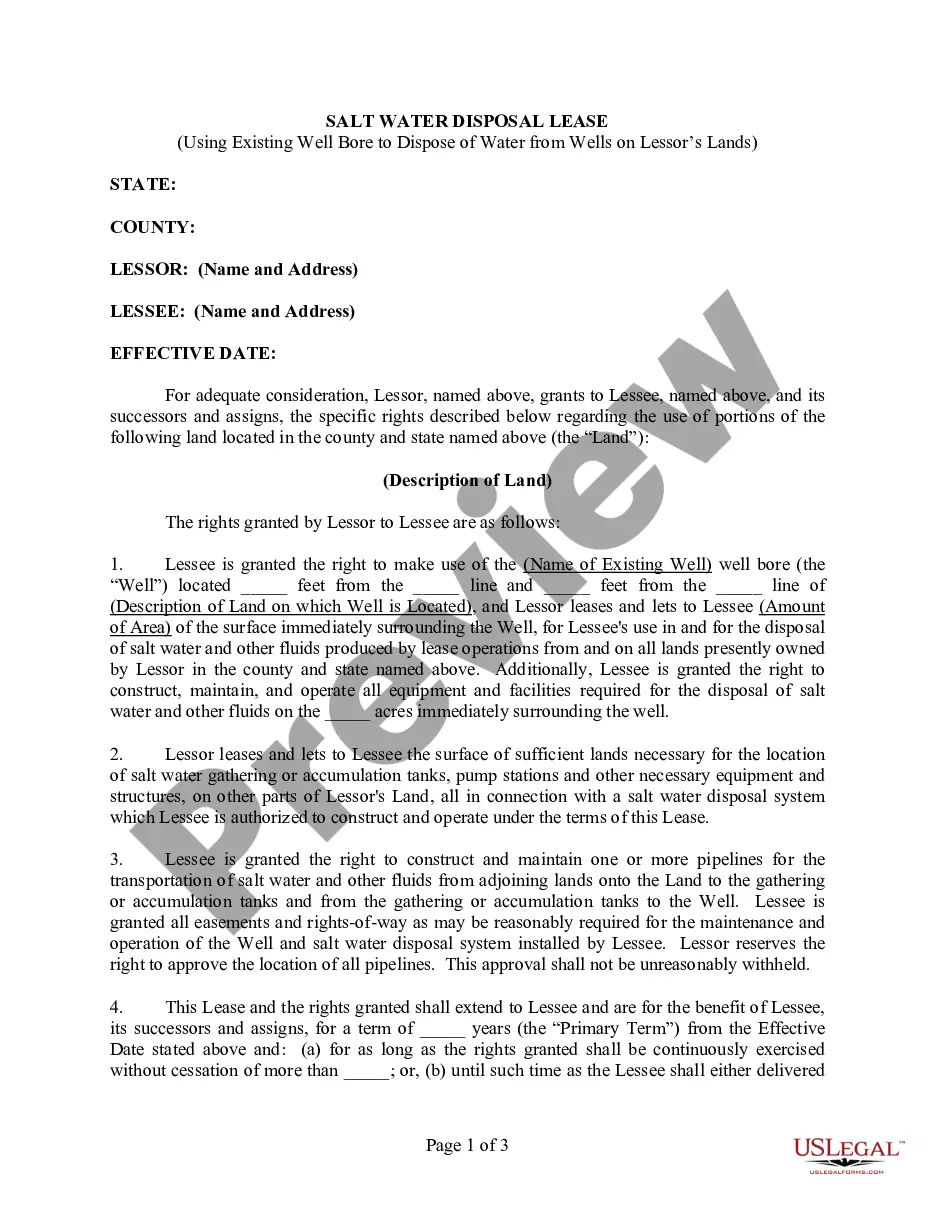

This lease rider form may be used when you are involved in a lease transaction, and have made the decision to utilize the form of Oil and Gas Lease presented to you by the Lessee, and you want to include additional provisions to that Lease form to address specific concerns you may have, or place limitations on the rights granted the Lessee in the standard lease form.

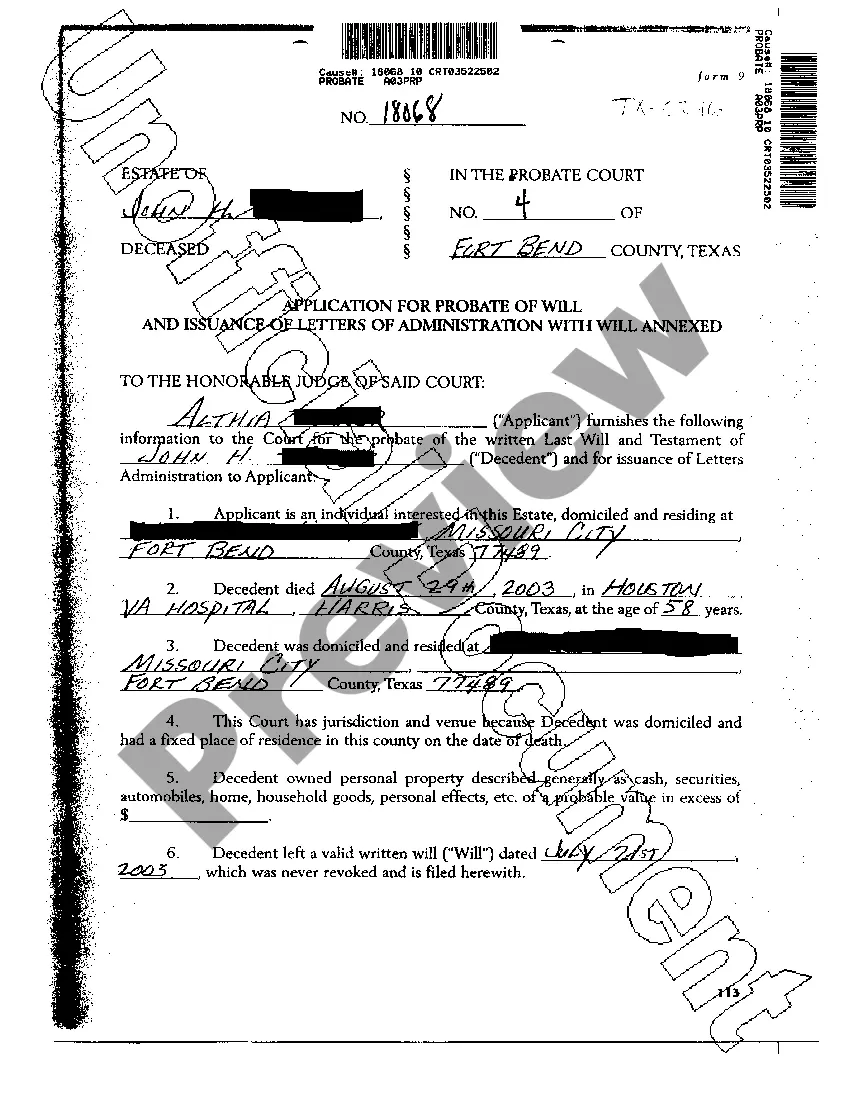

Texas Conversion of An Oil Or Gas Well to An injection Or Water Well

Description

How to fill out Conversion Of An Oil Or Gas Well To An Injection Or Water Well?

Have you been within a situation where you need to have papers for sometimes organization or individual reasons nearly every day? There are a lot of legal papers layouts available online, but finding types you can trust is not easy. US Legal Forms delivers thousands of type layouts, such as the Texas Conversion of An Oil Or Gas Well to An injection Or Water Well, which can be created to satisfy federal and state needs.

When you are currently familiar with US Legal Forms site and get your account, simply log in. Following that, you may down load the Texas Conversion of An Oil Or Gas Well to An injection Or Water Well template.

Unless you offer an accounts and want to begin to use US Legal Forms, adopt these measures:

- Obtain the type you will need and make sure it is for your correct town/area.

- Take advantage of the Preview option to review the shape.

- Browse the description to ensure that you have selected the right type.

- In case the type is not what you`re seeking, use the Lookup industry to find the type that meets your requirements and needs.

- Whenever you obtain the correct type, simply click Buy now.

- Opt for the pricing plan you want, fill in the required details to create your account, and pay money for the transaction using your PayPal or bank card.

- Select a convenient paper file format and down load your backup.

Locate each of the papers layouts you have purchased in the My Forms food selection. You can aquire a additional backup of Texas Conversion of An Oil Or Gas Well to An injection Or Water Well any time, if required. Just click the needed type to down load or produce the papers template.

Use US Legal Forms, by far the most comprehensive variety of legal forms, in order to save efforts and avoid faults. The assistance delivers expertly made legal papers layouts that can be used for an array of reasons. Create your account on US Legal Forms and begin producing your life easier.

Form popularity

FAQ

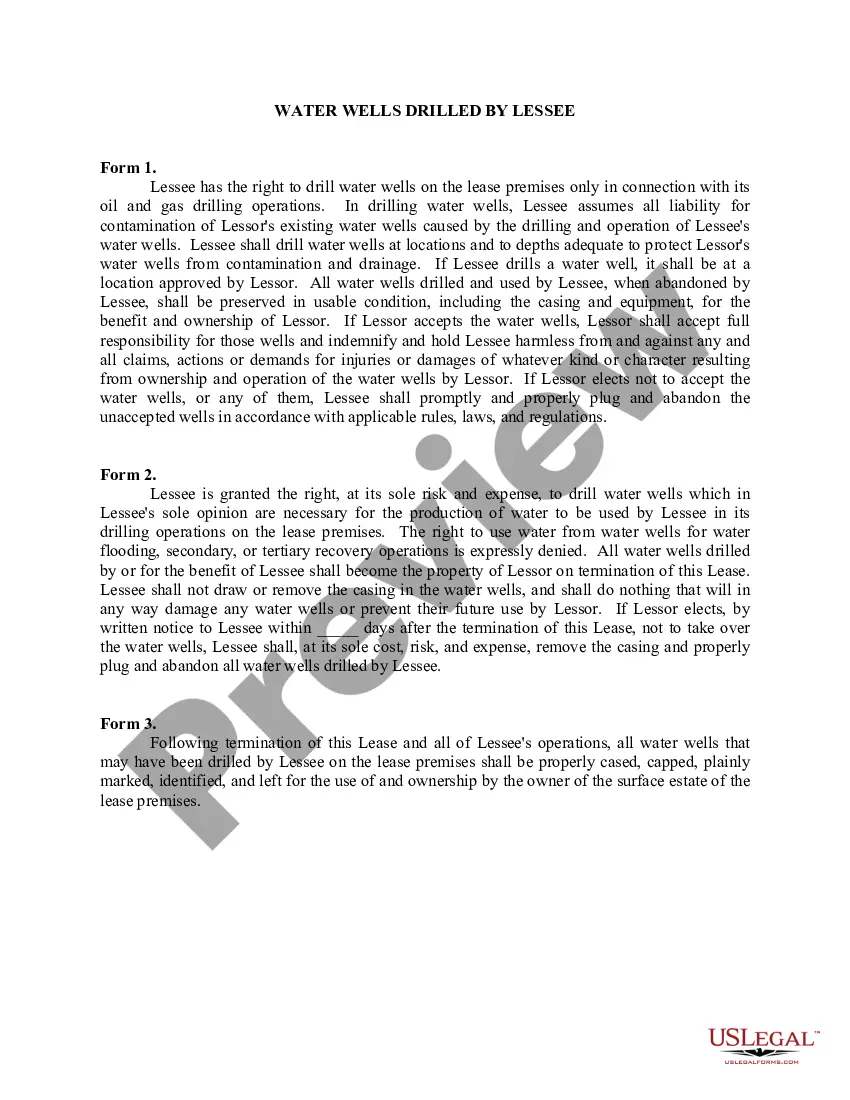

Public wells serve public water supply systems and are regulated by the Public Drinking Water Section of the TCEQ.

Private water well owners in Texas do not need to register their well unless the property falls within the jurisdiction of a groundwater conservation district (GCD). You can use the Texas Alliance of Groundwater Districts (TAGD) GCD Index to determine if your property falls within the boundary of a GCD.

An ?Exempt Well? is a well that does not require a Permit and is used solely for domestic purposes or for providing water for livestock, poultry or environmental flows that is drilled, completed, or equipped so that it is incapable of producing more than 25,000 gallons (17.4 gpm) of groundwater per day; . . .

Can I drill a well on my property? Texas operates under what's called a ?rule of capture,? which means if you own the land, you can drill a well there. If you're located within a groundwater conservation district, however, you'll have to abide by their regulations on groundwater withdrawal.

Texas has more than 54,700 permitted oil and gas injection and disposal wells with approximately 34,200 currently active as of July 2015. Of these 34,200 active injection and disposal wells, about 8,100 are wells that are used for disposal, the remainder (about 26,100) are injection wells.

Texas. The State of Texas doesn't require homeowners to be licensed in order to drill a well on their own property. Property owners must check with their Groundwater Conservation District for specific water well guidelines for their region.

The median cost of plugging a well without restoring the surface is about $20,000. Plugging and reclaiming the surface around the well?which may be done for aesthetic, environmental, or job creation reasons?increases the median cost to $76,000. Each additional 1,000 feet of well depth increases costs by 20 percent.