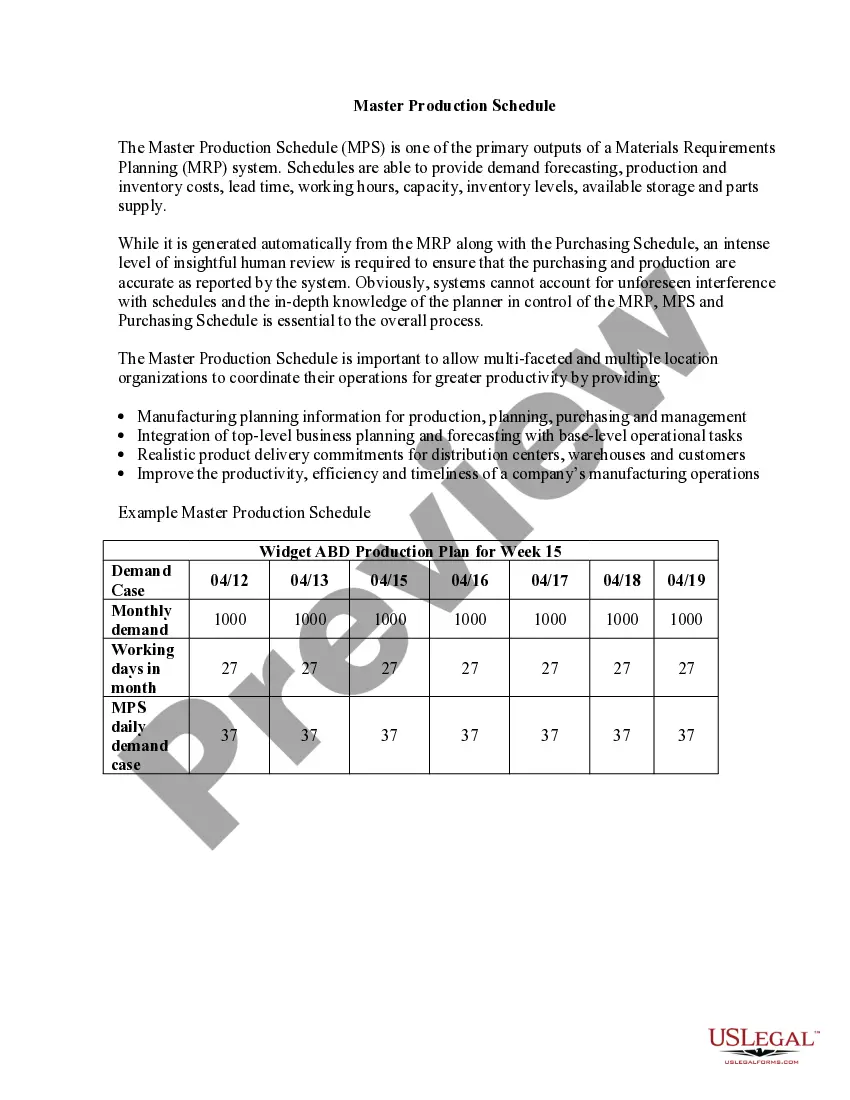

A Master Production Schedule (MPS) is a detailed plan used to manage the production of finished goods within a company. It is a key tool used by production planners to determine how many of each item should be produced, when it should be produced, and when it should be delivered. MPS typically takes into account customer orders, forecasted demand, available capacity, and supplier lead times. There are two main types of MPS: fixed-time and rolling. A fixed-time MPS is used when production is planned on a fixed timeline, such as a month or a year. A rolling MPS is used when production is planned over a rolling period, such as a week or two weeks. In both cases, the MPS is used to ensure that production is meeting customer demand and that sufficient inventory is available to meet demand.

Master Production Schedule

Description

How to fill out Master Production Schedule?

US Legal Forms is the most simple and profitable way to find appropriate legal templates. It’s the most extensive online library of business and personal legal documentation drafted and verified by legal professionals. Here, you can find printable and fillable blanks that comply with national and local regulations - just like your Master Production Schedule.

Getting your template requires just a few simple steps. Users that already have an account with a valid subscription only need to log in to the website and download the form on their device. Afterwards, they can find it in their profile in the My Forms tab.

And here’s how you can obtain a professionally drafted Master Production Schedule if you are using US Legal Forms for the first time:

- Read the form description or preview the document to make sure you’ve found the one corresponding to your demands, or locate another one using the search tab above.

- Click Buy now when you’re sure of its compatibility with all the requirements, and judge the subscription plan you like most.

- Register for an account with our service, sign in, and pay for your subscription using PayPal or you credit card.

- Decide on the preferred file format for your Master Production Schedule and download it on your device with the appropriate button.

Once you save a template, you can reaccess it whenever you want - simply find it in your profile, re-download it for printing and manual fill-out or import it to an online editor to fill it out and sign more efficiently.

Take full advantage of US Legal Forms, your reputable assistant in obtaining the required official paperwork. Give it a try!

Form popularity

FAQ

Material Requirements Planning (MRP) is a standard supply planning system to help businesses, primarily product-based manufacturers, understand inventory requirements while balancing supply and demand.

The components of a Master Production Schedule typically include the production plan, bill of materials, resource requirements, and delivery dates.

A master production schedule (MPS) delineates what products a manufacturer will produce, when and in what quantities. An MPS links sales demand with manufacturing capacity. The purpose of master production scheduling is to create a realistic plan that minimizes overstock while maximizing on-time delivery.

As the name implies, a master production schedule determines what products are manufactured, when they are produced, and in what quantities. The required raw materials are identified by the finished goods BOM, the data from which is integrated with current inventory data to create the MRP for raw materials procurement.

So, if I make a pen, it has a cap, a barrel, a spring. and a refill. Based on the definition above, the pen is an MPS item. The cap, barrel, spring and refill are MRP items.

Material requirements planning (MRP) is a software-based integrated inventory and supply management system that companies use to estimate quantities of raw materials and schedule production.