Maintenance Engineer Checklist

Description

How to fill out Maintenance Engineer Checklist?

Among numerous free and paid examples which you find on the internet, you can't be sure about their accuracy. For example, who made them or if they’re qualified enough to deal with the thing you need those to. Keep calm and use US Legal Forms! Locate Maintenance Engineer Checklist templates made by skilled legal representatives and get away from the expensive and time-consuming process of looking for an attorney and after that paying them to draft a papers for you that you can find on your own.

If you already have a subscription, log in to your account and find the Download button next to the form you’re trying to find. You'll also be able to access all your previously downloaded samples in the My Forms menu.

If you’re utilizing our website the very first time, follow the guidelines below to get your Maintenance Engineer Checklist with ease:

- Make sure that the file you see is valid in your state.

- Review the file by reading the information for using the Preview function.

- Click Buy Now to start the purchasing process or look for another example utilizing the Search field located in the header.

- Choose a pricing plan and create an account.

- Pay for the subscription with your credit/debit/debit/credit card or Paypal.

- Download the form in the required format.

As soon as you have signed up and purchased your subscription, you can utilize your Maintenance Engineer Checklist as many times as you need or for as long as it continues to be valid in your state. Edit it with your favorite offline or online editor, fill it out, sign it, and print it. Do far more for less with US Legal Forms!

Form popularity

FAQ

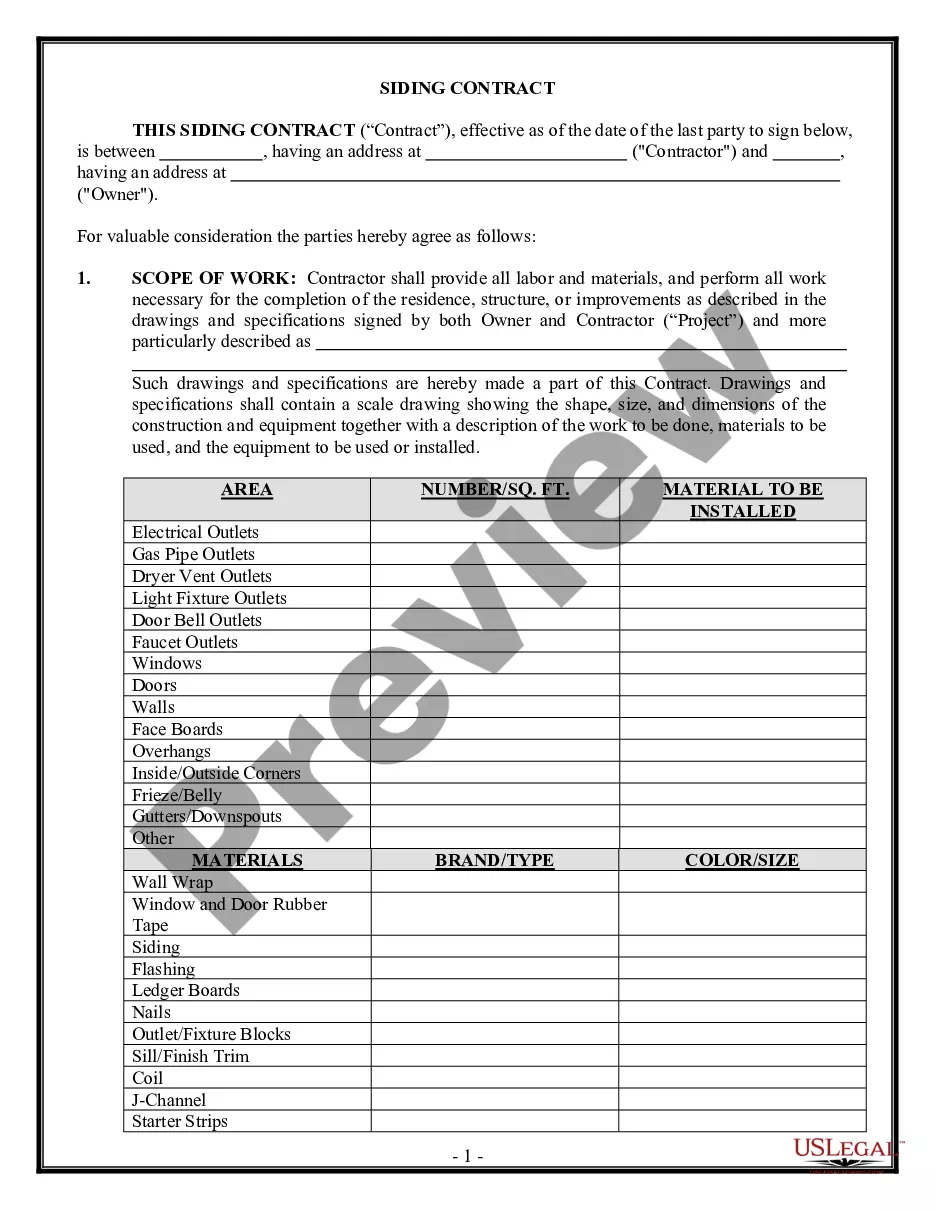

A checklist is a list of items you need to verify or check or inspect. They are used in a variety of fields from construction to health service. A preventive maintenance checklist helps to identify maintenance actions on equipment to maintain it in good conditions and to improve plant reliability.

Lubricating, cleaning, or adjusting machinery. Inspecting equipment to ensure proper operation and safety. Replacing parts that show deterioration. Checking, testing, and maintaining safety equipment, such as safety barriers, fire extinguishers, or alarm systems.

Example tasks may include cleaning, lubrication, replacing or repairing parts, or even partial or complete overhauls. More obvious examples of preventive maintenance include ensuring production line equipment is working efficiently or heating, ventilation or air conditioning elements are inspected, cleaned and updated.

Four general types of maintenance philosophies can be identified, namely corrective, preventive, risk-based and condition-based maintenance.

Preventive maintenance involves the systematic inspection of equipment where potential problems are detected and corrected in order to prevent equipment failure before it happens.

Get the Right People on the Maintenance Team. Set Goals for the Preventative Maintenance (PM) Plan. Collect Detailed Information on Existing Equipment. Decide Which Assets and Equipment to Include. Create the Preventative Maintenance Schedule.

A preventive maintenance checklist is a set of written tasks that guide the technician through a PM before it can be closed. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.

A checklist is a list of items you need to verify or check or inspect. They are used in a variety of fields from construction to health service. A preventive maintenance checklist helps to identify maintenance actions on equipment to maintain it in good conditions and to improve plant reliability.