Approval of Clean Up (Fiber Optic System)

Description

How to fill out Approval Of Clean Up (Fiber Optic System)?

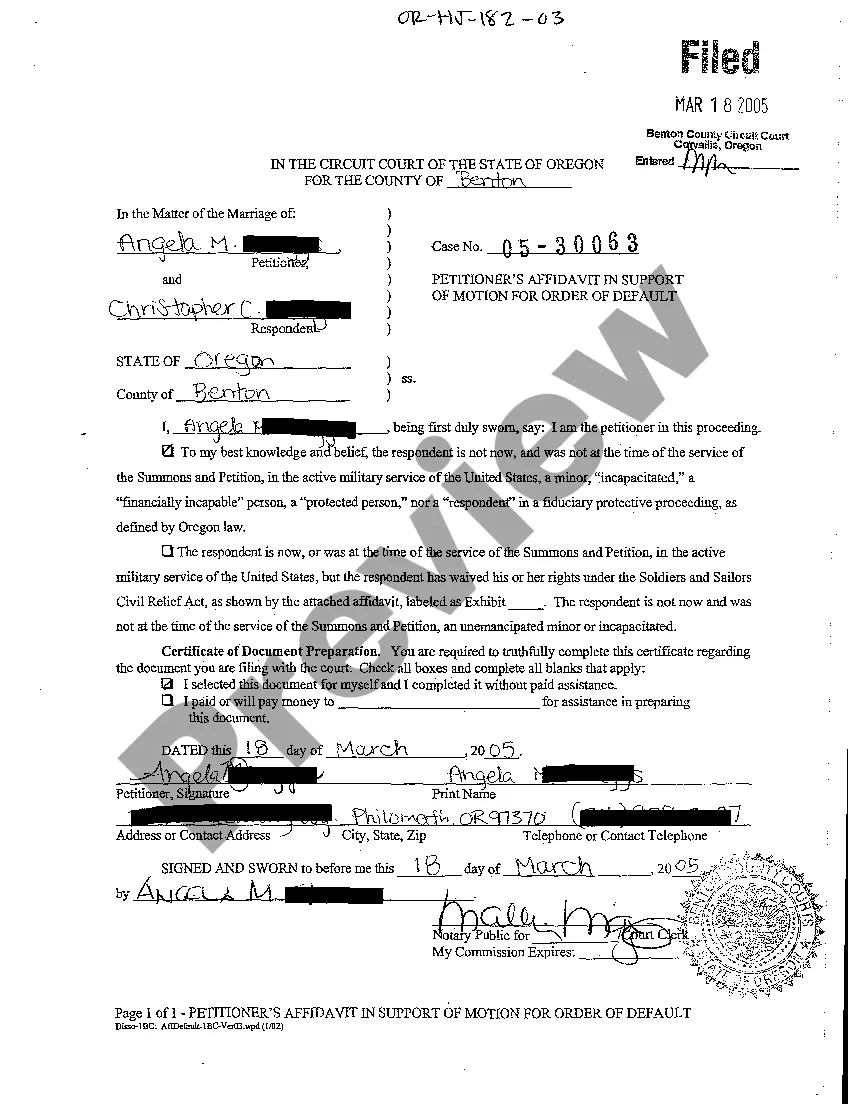

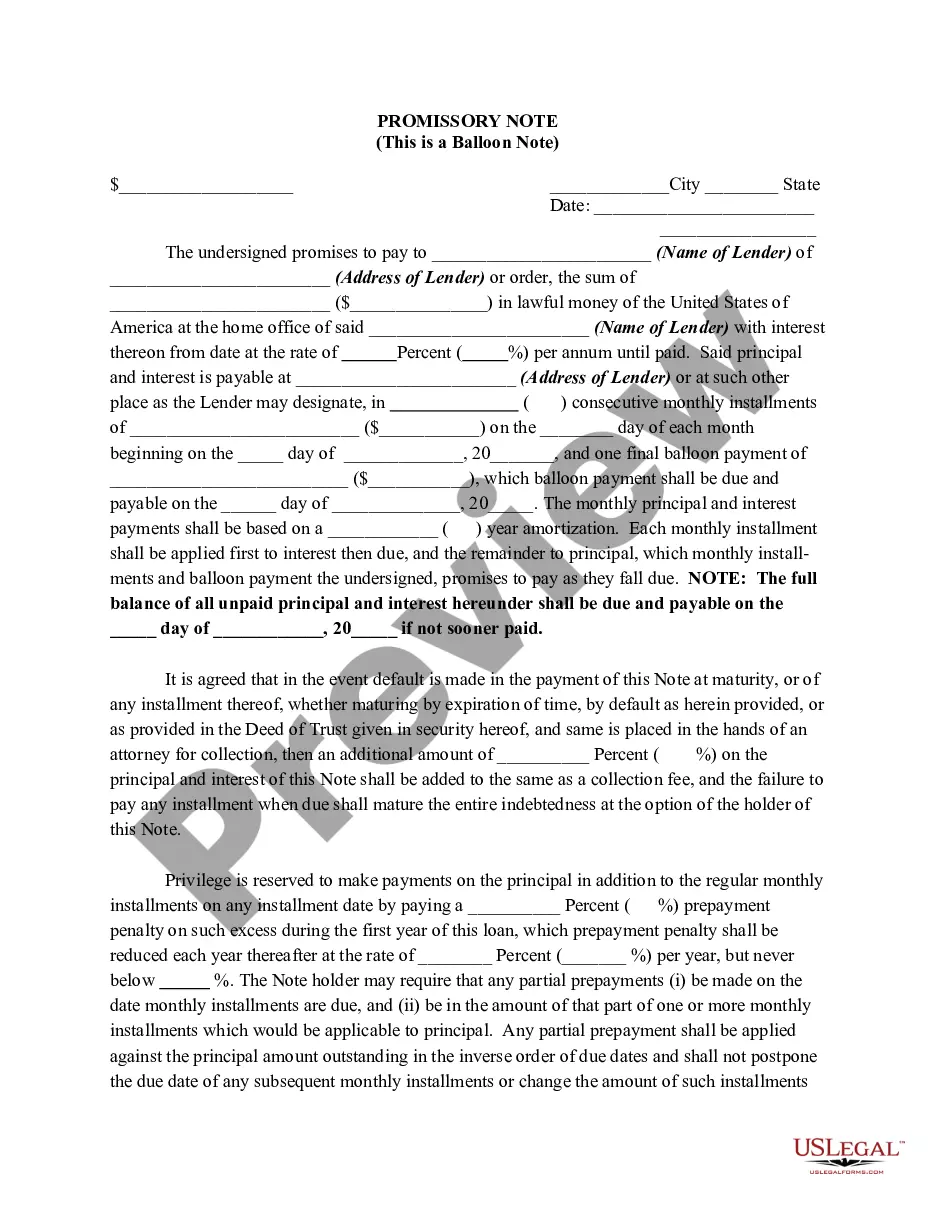

When it comes to drafting a legal document, it is easier to leave it to the specialists. Nevertheless, that doesn't mean you yourself cannot find a sample to use. That doesn't mean you yourself cannot get a sample to utilize, however. Download Approval of Clean Up (Fiber Optic System) straight from the US Legal Forms website. It gives you a wide variety of professionally drafted and lawyer-approved documents and samples.

For full access to 85,000 legal and tax forms, customers just have to sign up and select a subscription. Once you’re registered with an account, log in, look for a particular document template, and save it to My Forms or download it to your device.

To make things easier, we’ve provided an 8-step how-to guide for finding and downloading Approval of Clean Up (Fiber Optic System) quickly:

- Be sure the document meets all the necessary state requirements.

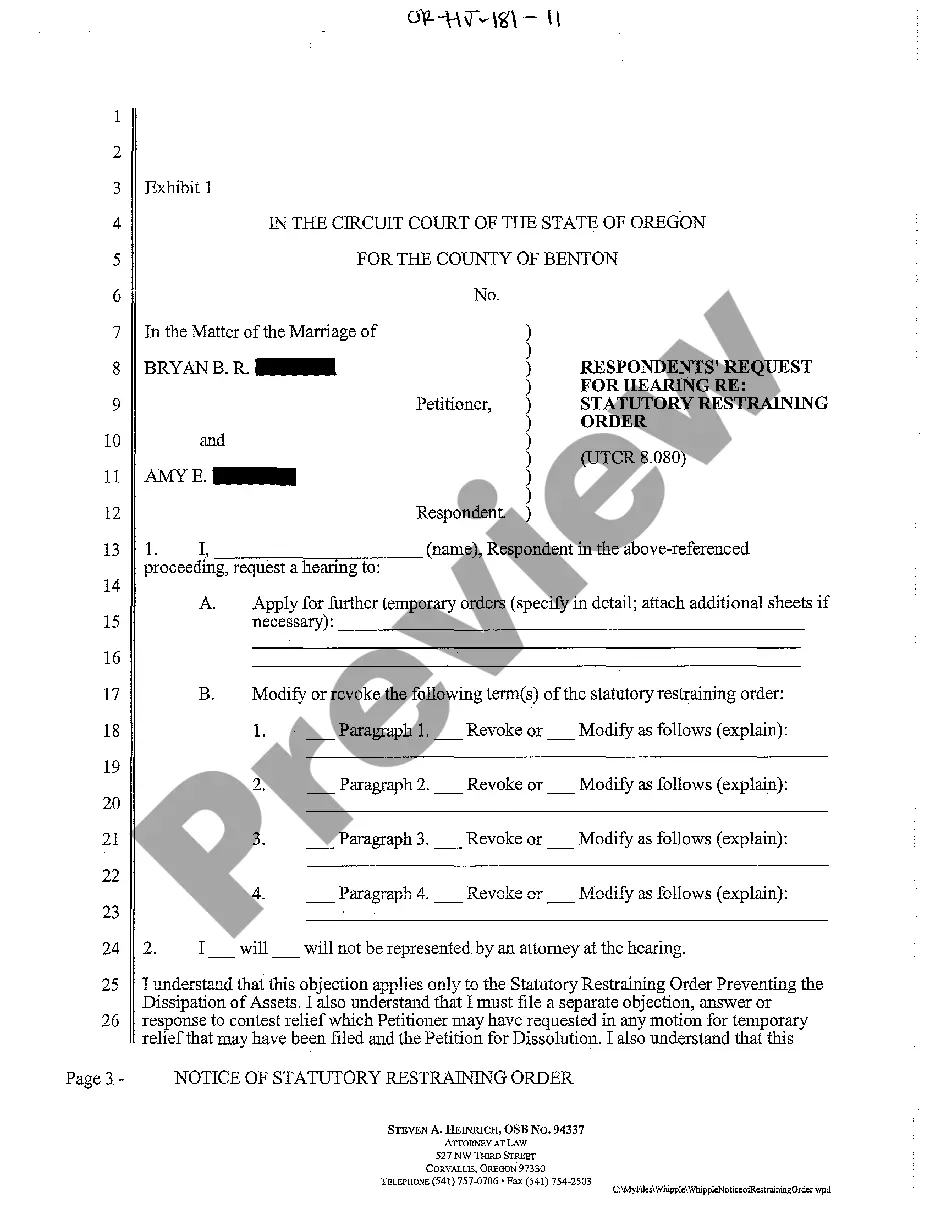

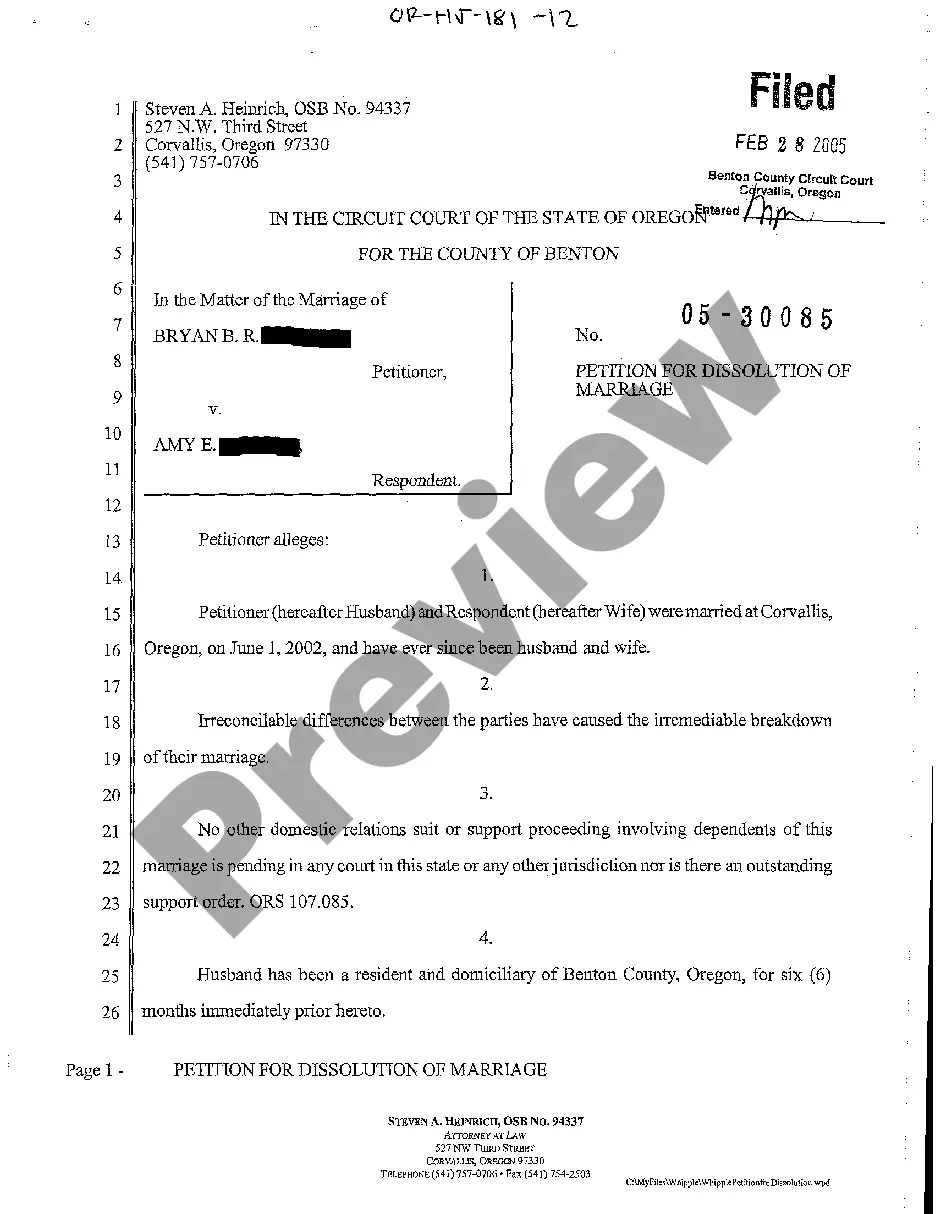

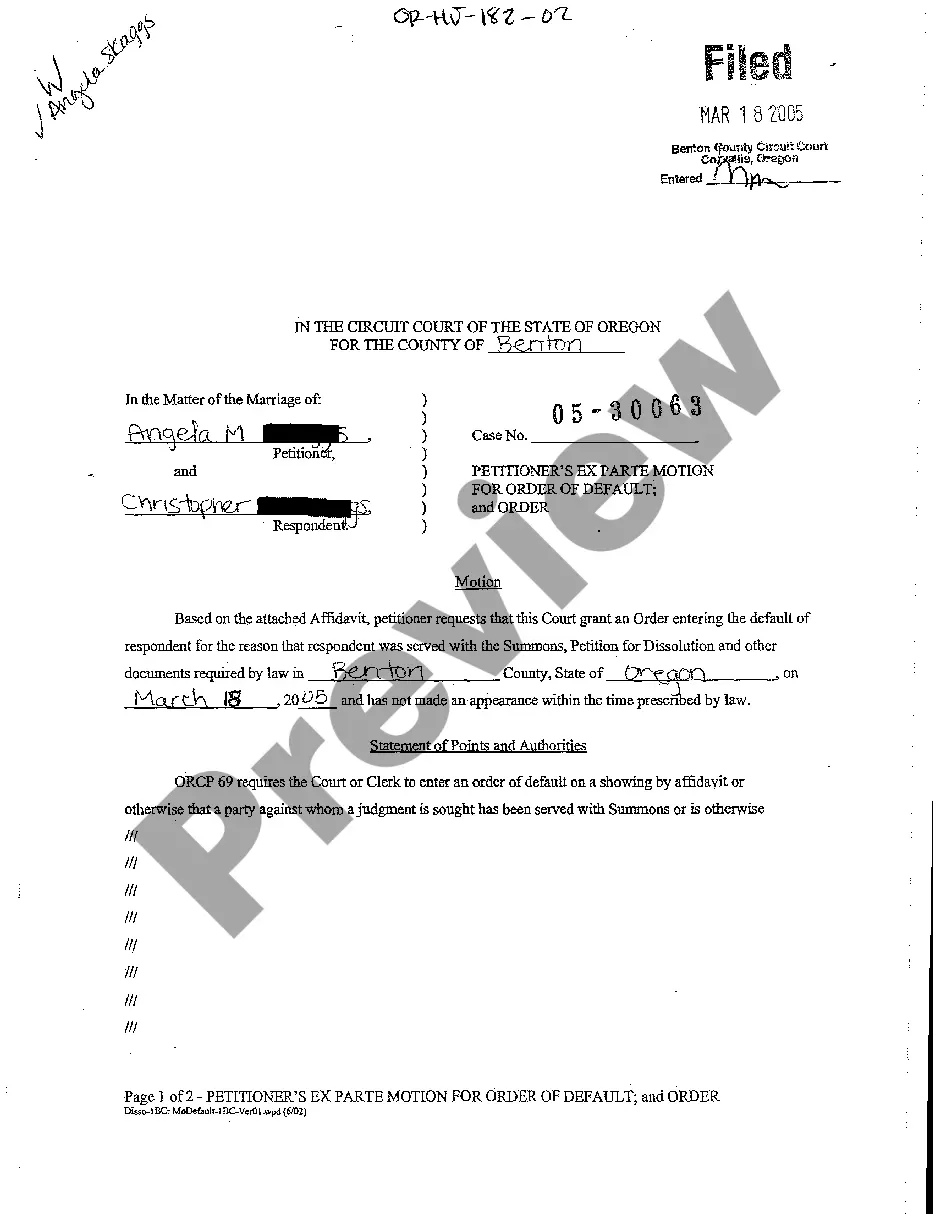

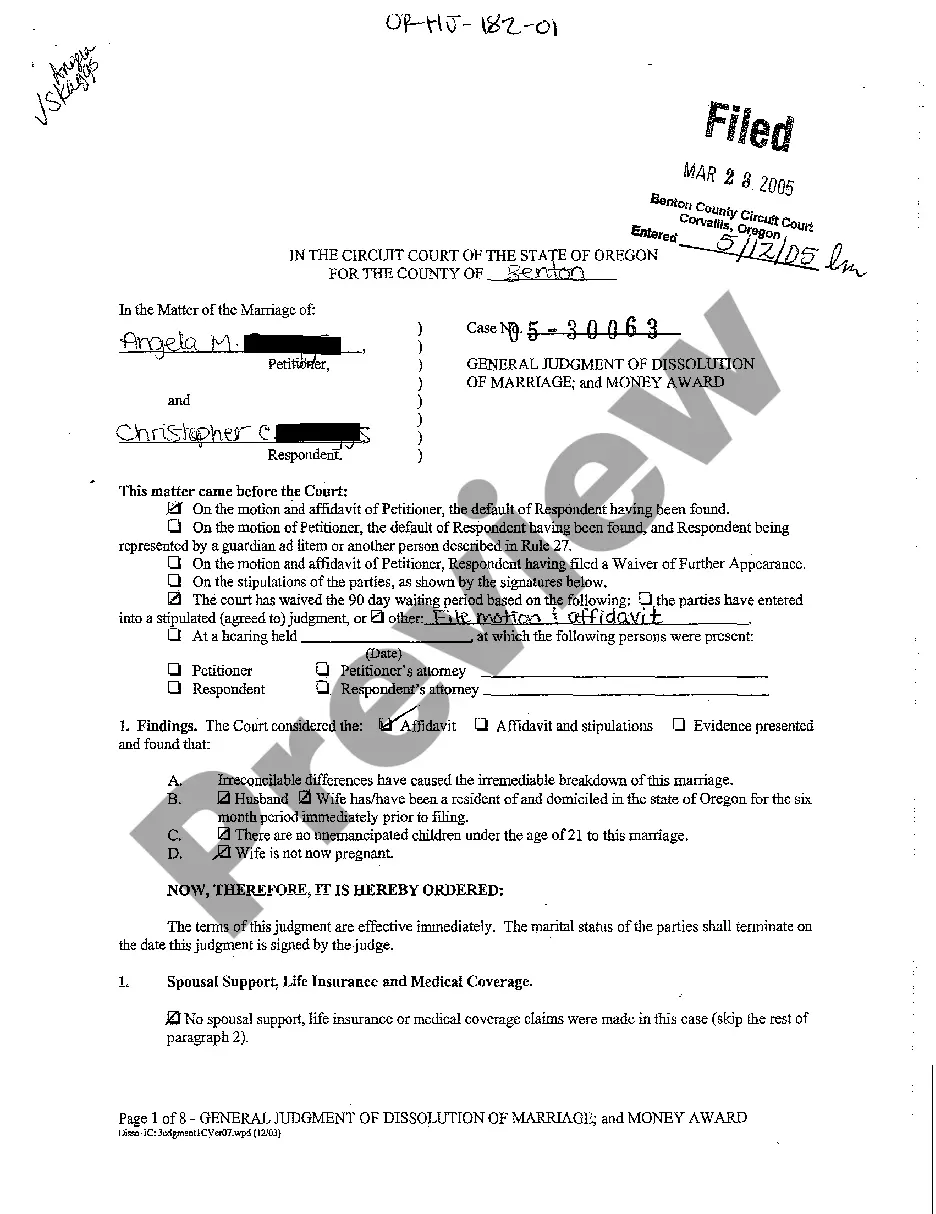

- If available preview it and read the description before buying it.

- Hit Buy Now.

- Choose the suitable subscription to meet your needs.

- Make your account.

- Pay via PayPal or by debit/visa or mastercard.

- Select a needed format if several options are available (e.g., PDF or Word).

- Download the document.

As soon as the Approval of Clean Up (Fiber Optic System) is downloaded you are able to complete, print out and sign it in any editor or by hand. Get professionally drafted state-relevant files in a matter of seconds in a preferable format with US Legal Forms!

Form popularity

FAQ

Avoiding Dirty Fiber: Cleaning and Inspection of Optical Fiber Connectors. Cleanliness of fiber optic connections is critical to the performance of optical communication networks.Dirty fiber that blocks the fiber core generates strong back reflections (Return Loss), and may impact attenuation (Insertion Loss).

A suitable source for an optical fiber communications system must have certain characteristics which include the following: emission at a wavelength within a window of low fiber transmission loss, efficient conversion of prime power to light coupled into the fiber, high reliability, ease of modulation, adequate

An optical fiber-end face must be flat, smooth, and perpendicular to the fiber's axis to ensure proper fiber connection. Light is reflected or scattered at the connection interface unless the connecting fiber end faces are properly prepared.

IEC Standard 61300-3-35 is a global common set of requirements for fiber optic connector end face quality designed to guarantee insertion loss and return loss performance.

Dry cleaning, cleaning with isopropyl alcohol, and wet cleaning of connectors provide poor results. The best fiber optic connector cleaning method is the combination cleaning method. This technique involves using a small amount of solvent on a wiping material and immediately drying the surface.

For plastic optical fibers, the fiber core size ranges from 0.25mm to 3mm of which 1mm is the most popular.

When you unplug a fiber-optic cable from a transceiver, place rubber safety caps over the transceiver and on the end of the cable. Anchor fiber-optic cables to prevent stress on the connectors. Avoid bending fiber-optic cables beyond their minimum bend radius.

For multimode fiber, the loss is about 3 dB per km for 850 nm sources, 1 dB per km for 1300 nm. (3.5 and 1.5 dB/km max per EIA/TIA 568) This roughly translates into a loss of 0.1 dB per 100 feet (30 m) for 850 nm, 0.1 dB per 300 feet(100 m) for 1300 nm.

Benefits to using the IEC 61300-3-35 standard for fiber-endface measurement and inspection.