Utah Toll Manufacturing Agreement

Description

How to fill out Toll Manufacturing Agreement?

If you need to finish, obtain, or print legal document templates, utilize US Legal Forms, the largest collection of legal forms available online.

Take advantage of the site’s simple and user-friendly search to find the documents you need.

Various templates for business and personal purposes are organized by categories and states, or keywords. Use US Legal Forms to fetch the Utah Toll Manufacturing Agreement in just a few clicks.

Every legal document template you purchase is yours indefinitely. You will have access to each form you downloaded in your account.

Stay competitive and obtain, and print the Utah Toll Manufacturing Agreement with US Legal Forms. There are millions of professional and state-specific forms available for your business or personal needs.

- If you are already a US Legal Forms customer, Log In to your account and click the Acquire button to get the Utah Toll Manufacturing Agreement.

- You can also access forms you previously downloaded in the My documents section of your account.

- If this is your first time using US Legal Forms, follow the instructions below.

- Step 1. Ensure you have chosen the form for your specific city/state.

- Step 2. Utilize the Preview option to review the form’s content. Don't forget to check the summary.

- Step 3. If you are not satisfied with the form, use the Search area at the top of the screen to find other versions of the legal form template.

- Step 4. Once you have found the form you need, click the Buy now button. Select the pricing plan you prefer and enter your details to register for an account.

- Step 5. Complete the transaction. You can use your Visa or MasterCard or PayPal account to finalize the payment.

- Step 6. Download the legal document template and save it to your device.

- Step 7. Fill in, modify, and print or sign the Utah Toll Manufacturing Agreement.

Form popularity

FAQ

Toll manufacturing signifies that the client supplies the raw materials, while contract manufacturing may include the supplier providing those materials. Although both agreements allow businesses to outsource production, the key distinction lies in material ownership and sourcing. Entering a Utah Toll Manufacturing Agreement can clarify these aspects, ensuring that businesses can optimize their operations and costs effectively.

Toll processing refers to the service of processing raw materials into final products on behalf of clients, who retain ownership of the inputs. This service is beneficial for companies looking to optimize production without the associated capital expenditures. Utilizing a Utah Toll Manufacturing Agreement enables businesses to take advantage of specialized processing capabilities, effectively scaling their production needs.

In SAP, toll manufacturing is an integrated process that allows businesses to manage production activities outsourced to third-party manufacturers. This system streamlines operations by maintaining oversight of inventory and facilitating tracking of costs involved in the manufacturing process. By embracing a Utah Toll Manufacturing Agreement, companies can leverage SAP functionalities to efficiently manage their tolling relationships.

Tolling manufacturing refers to the practice where a third party manufactures products for a client using the client's materials. This arrangement is beneficial because it allows for flexibility and reduced costs. By entering into a Utah Toll Manufacturing Agreement, businesses can focus on their core operations while leveraging the expertise of specialized manufacturers.

The toll manufacturing process involves a company contracting another company to produce products on its behalf. Essentially, the contract manufacturer uses their own equipment and facilities to create products for the client, who supplies the raw materials. In the context of a Utah Toll Manufacturing Agreement, this process allows businesses to increase output without investing in new infrastructure.

Toll manufacturing offers several advantages, such as reducing overhead costs and minimizing the need for significant capital investment. Companies can access specialized expertise and infrastructure without the burden of direct production management. A Utah Toll Manufacturing Agreement allows businesses to respond more quickly to market demands while ensuring high-quality output through established manufacturing standards.

A toll agreement is a type of contract that allows one party to produce goods for another party using its raw materials or inputs. This arrangement is particularly beneficial when companies want to outsource manufacturing while reducing capital investment. By utilizing a Utah Toll Manufacturing Agreement, businesses can streamline operations and focus on their core competencies without worrying about facility maintenance.

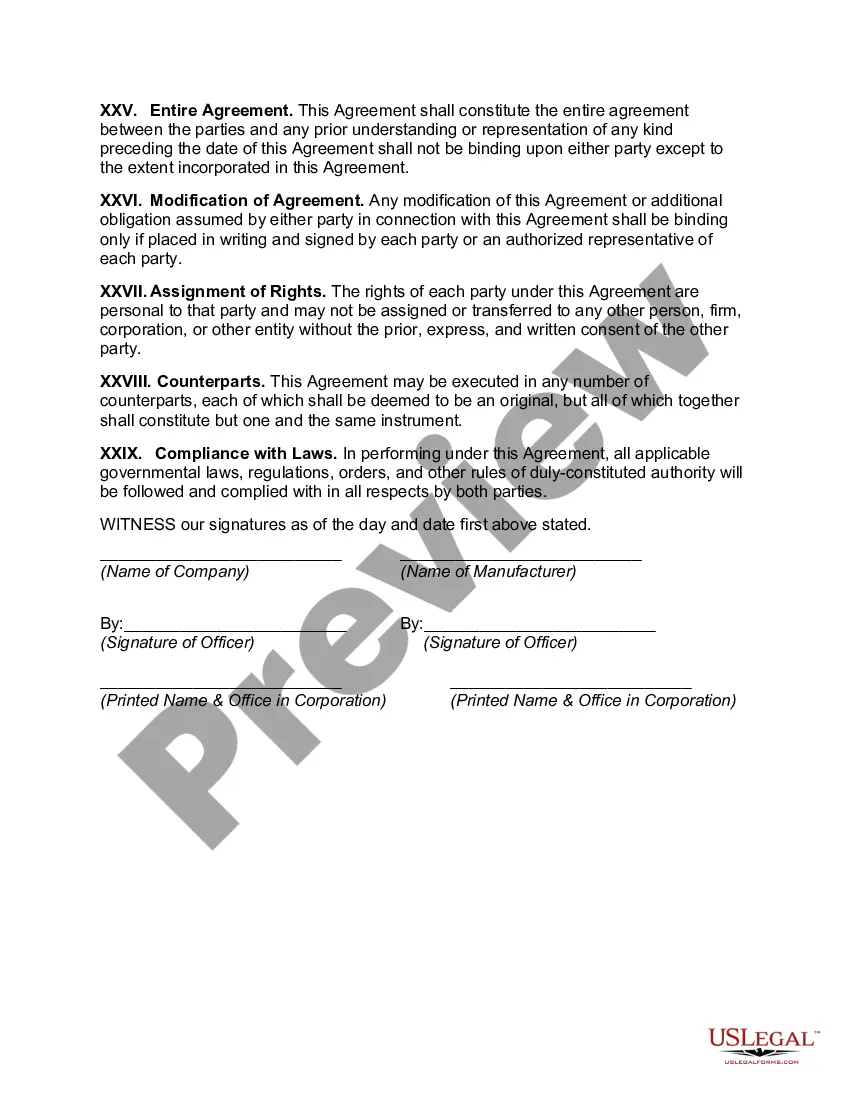

A toll manufacturing agreement is a contract between a company and a manufacturer where the manufacturer produces goods on behalf of the company. This agreement outlines the specific terms, such as production processes, quality standards, and payment structures. In the context of a Utah Toll Manufacturing Agreement, businesses can leverage local manufacturers to enhance production efficiency while maintaining control over their product specifications.

The main difference lies in their roles within the production process. Manufacturers create products from raw materials, while subcontractors may provide specific tasks such as assembly, packaging, or component production. Understanding this distinction is crucial when drafting a Utah Toll Manufacturing Agreement, as it helps establish clear responsibilities and expectations for all parties involved.

Subcontract manufacturing involves hiring another company to produce goods on behalf of your business. This method allows businesses to focus on their core competencies while relying on the expertise of subcontractors for manufacturing. A well-structured Utah Toll Manufacturing Agreement can include terms related to subcontract manufacturers, ensuring quality, timelines, and costs align with your business goals.