Utah Maintenance Engineer Checklist

Description

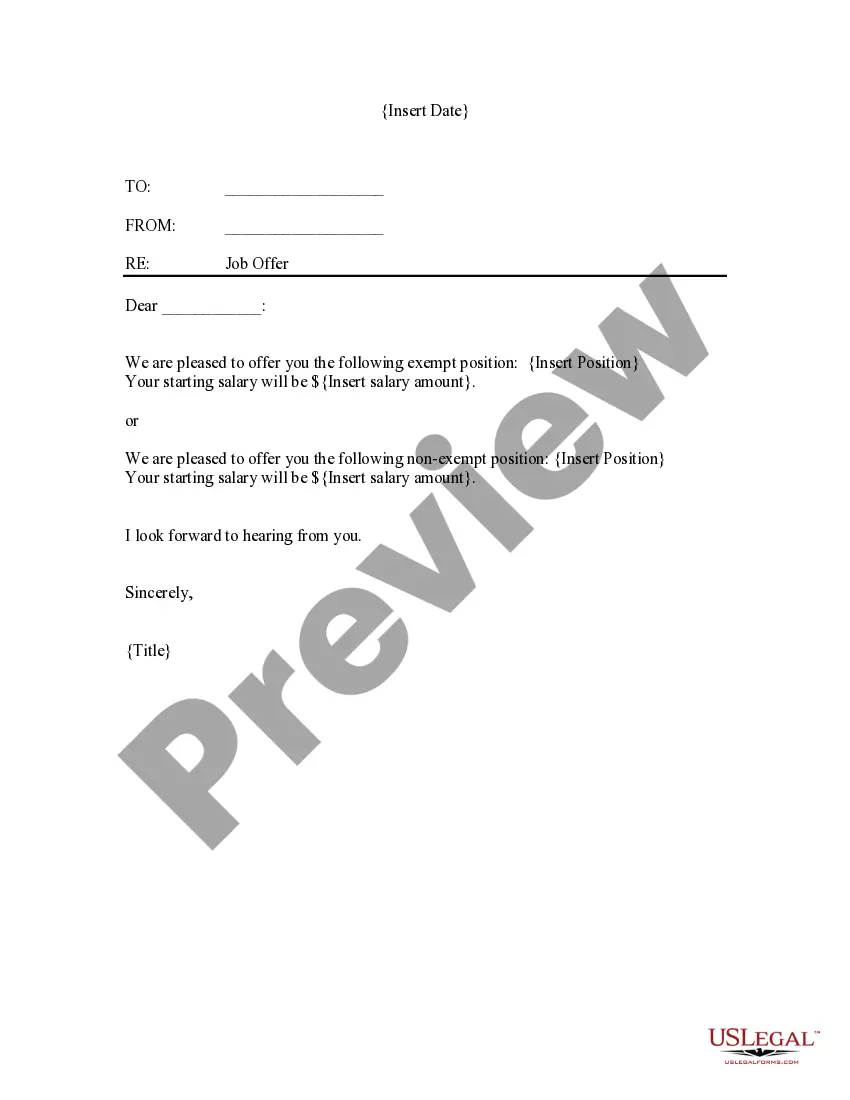

How to fill out Maintenance Engineer Checklist?

Selecting the appropriate official document format can be rather challenging.

Clearly, there are numerous templates available online, but how can you find the official type that you need.

Utilize the US Legal Forms site. The service provides thousands of templates, including the Utah Maintenance Engineer Checklist, which you can use for business and personal purposes.

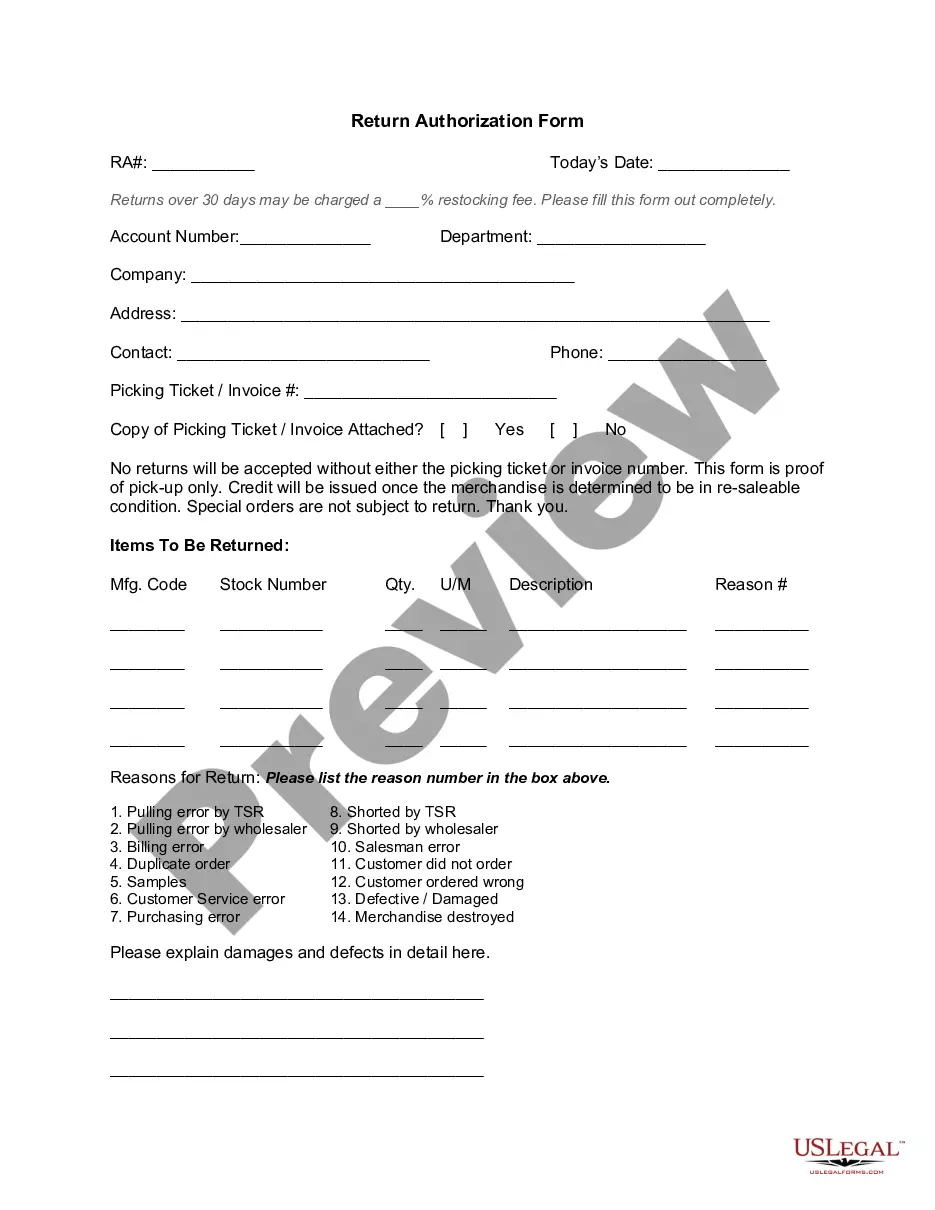

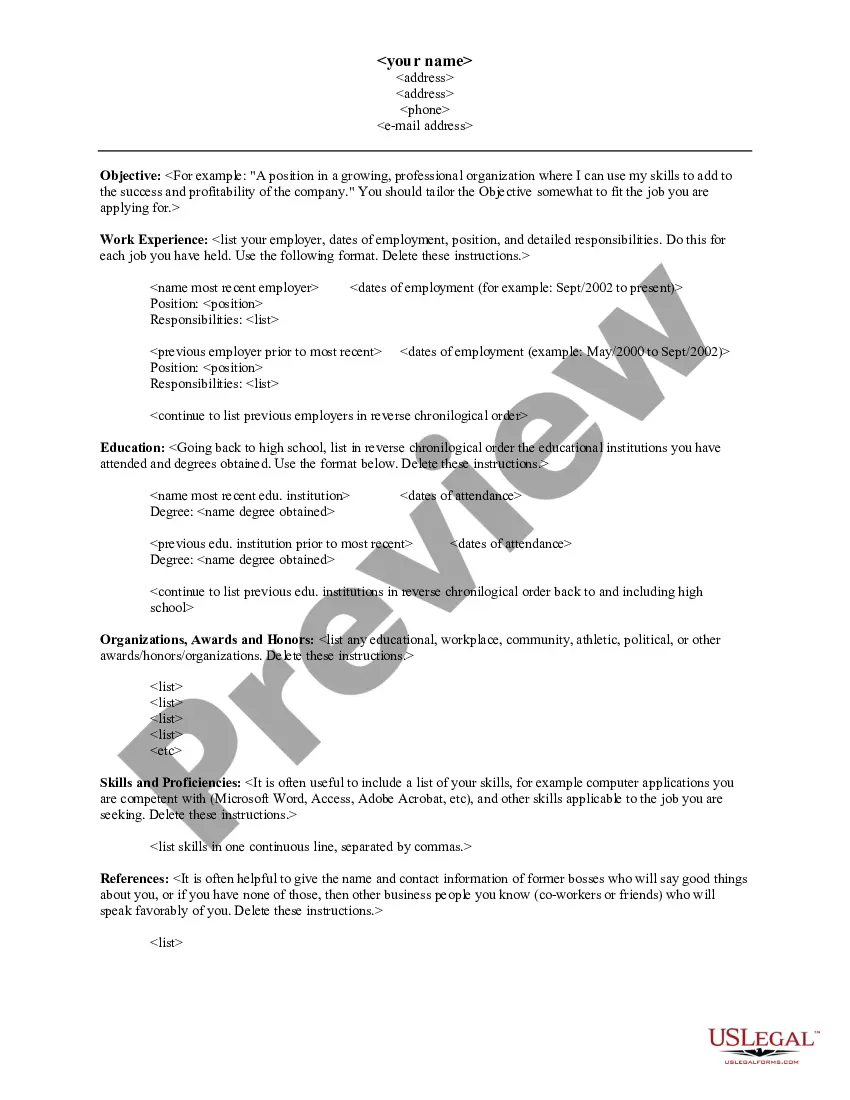

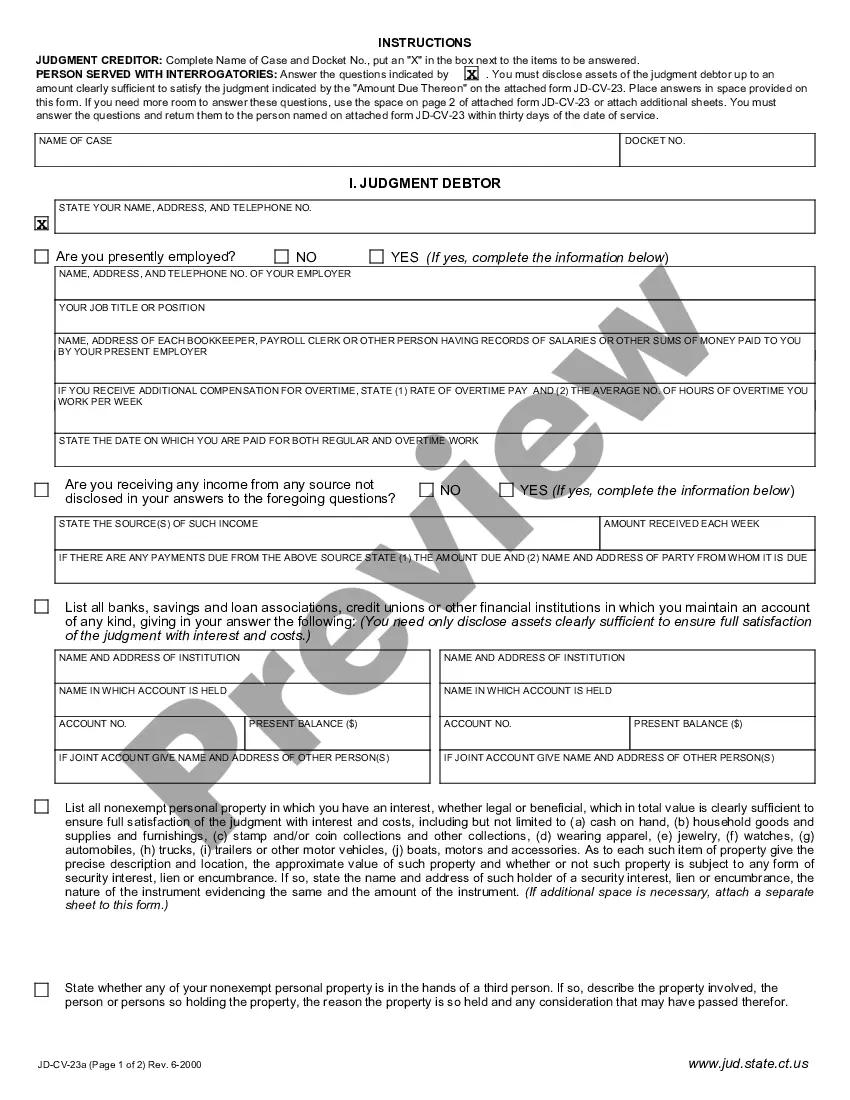

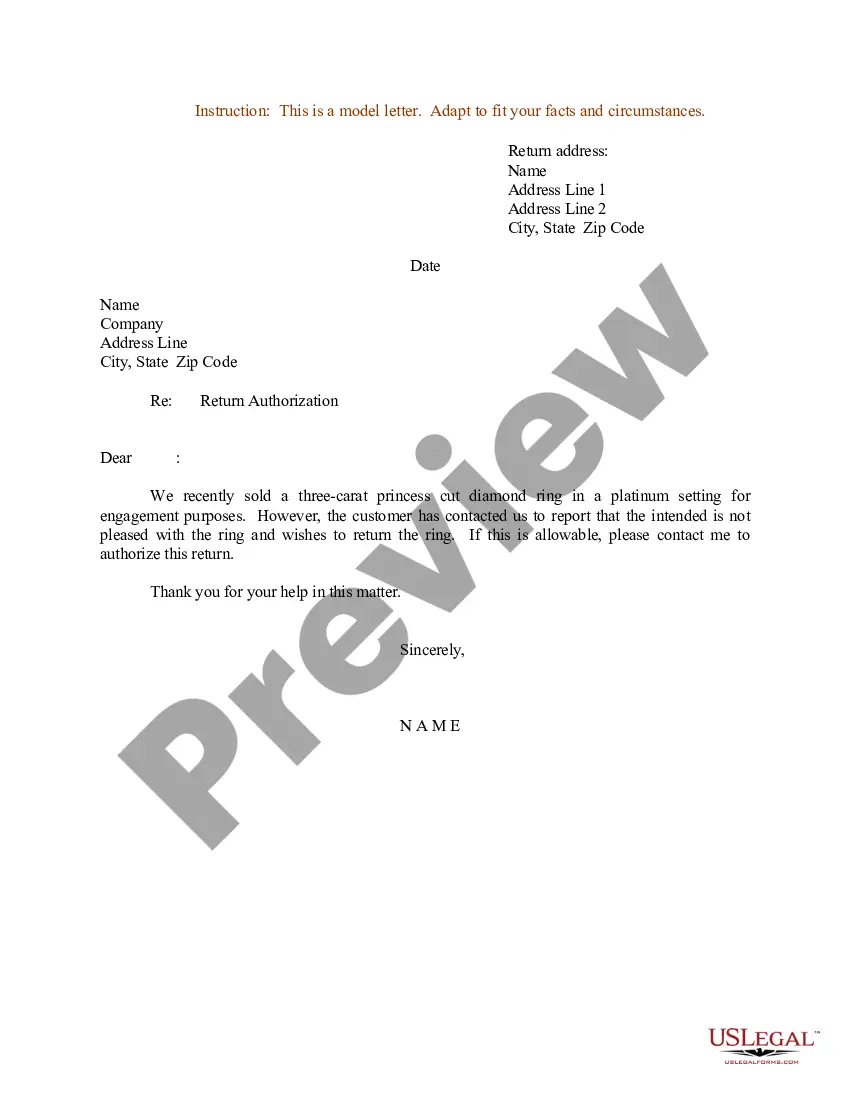

You can review the form using the Review button and read the form description to confirm it is the right one for you.

- All of the forms are reviewed by professionals and comply with state and federal regulations.

- If you are already a registered user, Log In to your account and click the Download button to get the Utah Maintenance Engineer Checklist.

- Use your account to browse the official forms you have previously acquired.

- Go to the My documents tab in your account and download another copy of the document you require.

- If you are a new user of US Legal Forms, here are simple steps you can follow.

- First, ensure you have chosen the correct type for your jurisdiction.

Form popularity

FAQ

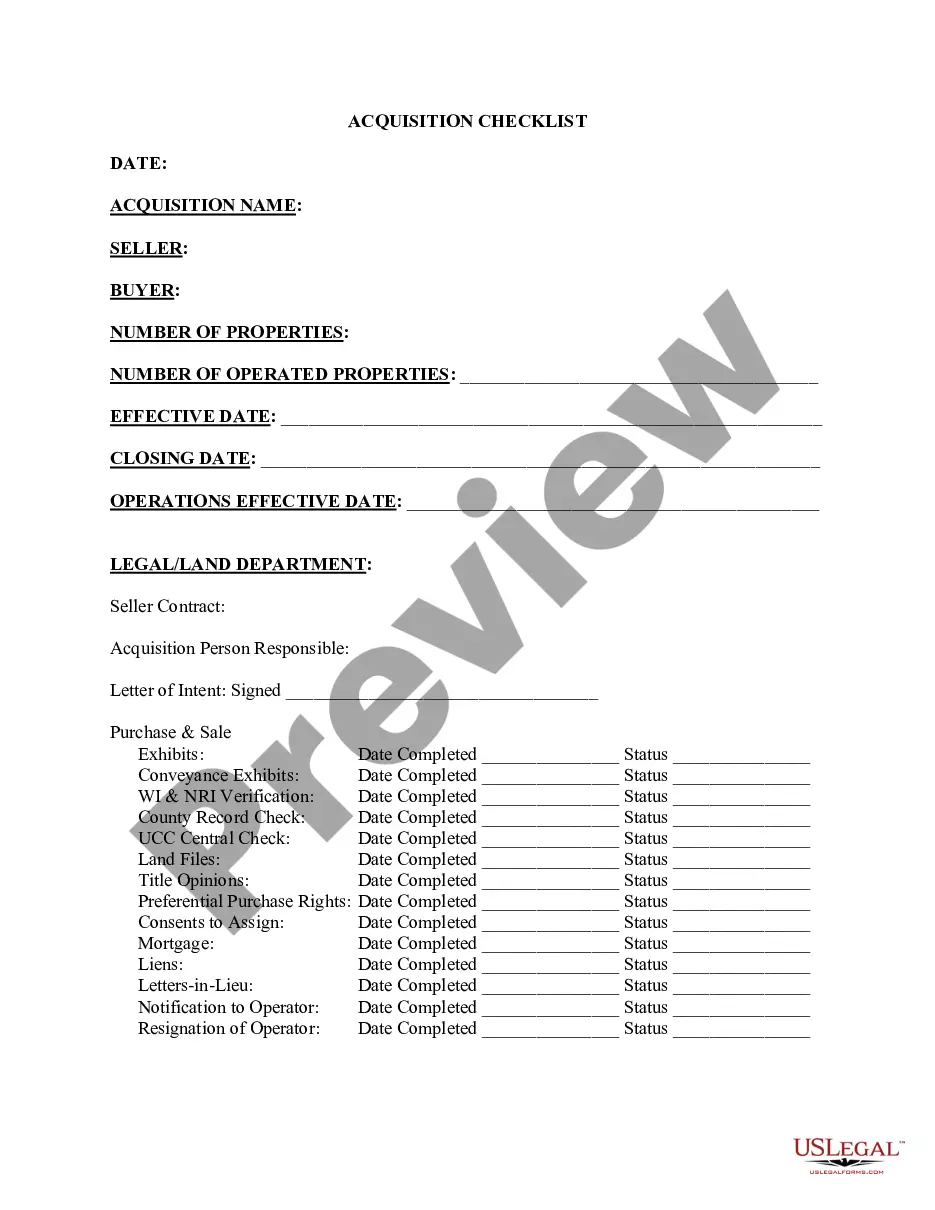

Examples of routine maintenance Routine maintenance in a factory setting involves lubricating, cleaning, and adjusting machines, replacing equipment parts on a schedule, inspecting certain components, or performing conditioned monitoring exercises.

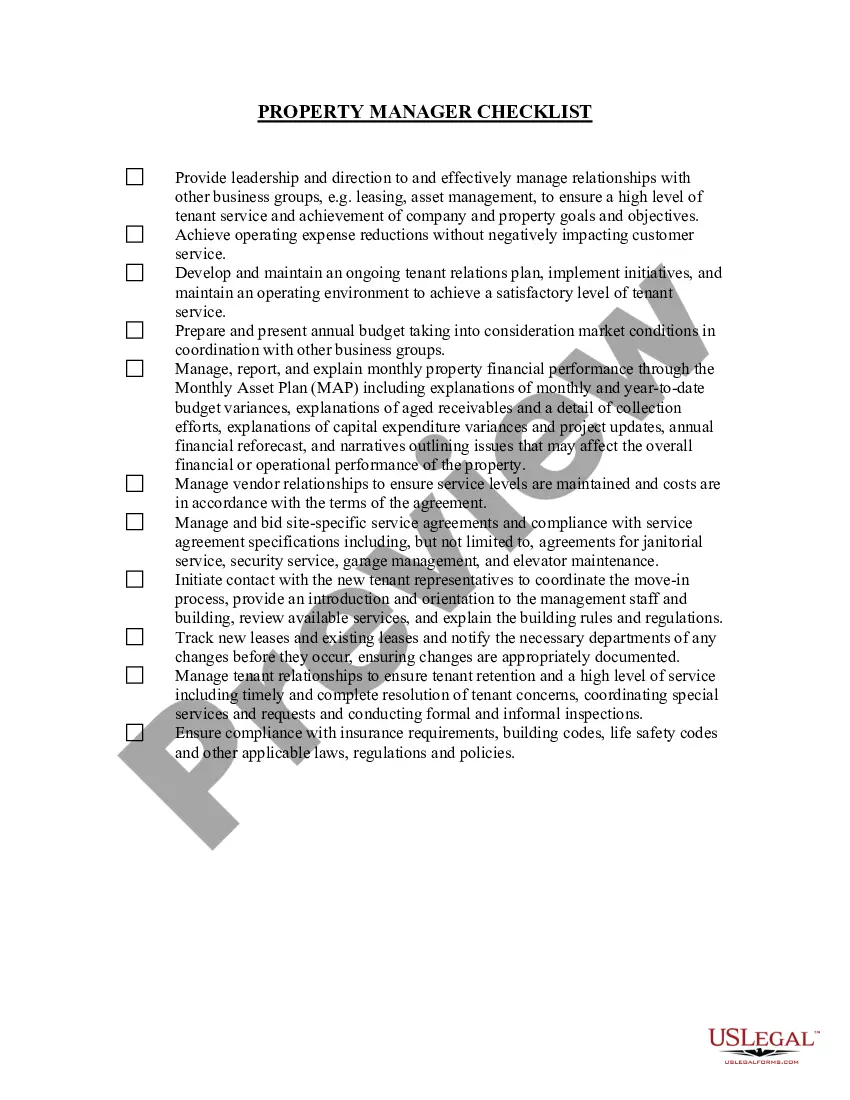

A preventive maintenance checklist is a set of tasks that the technician needs to complete in order to close a preventive maintenance work order. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.

A preventive maintenance checklist is a set of tasks that the technician needs to complete in order to close a preventive maintenance work order. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.

Typical examples of routine maintenance include:Lubricating, cleaning, or adjusting machinery.Inspecting equipment to ensure proper operation and safety.Replacing parts that show deterioration.Checking, testing, and maintaining safety equipment, such as safety barriers, fire extinguishers, or alarm systems.More items...

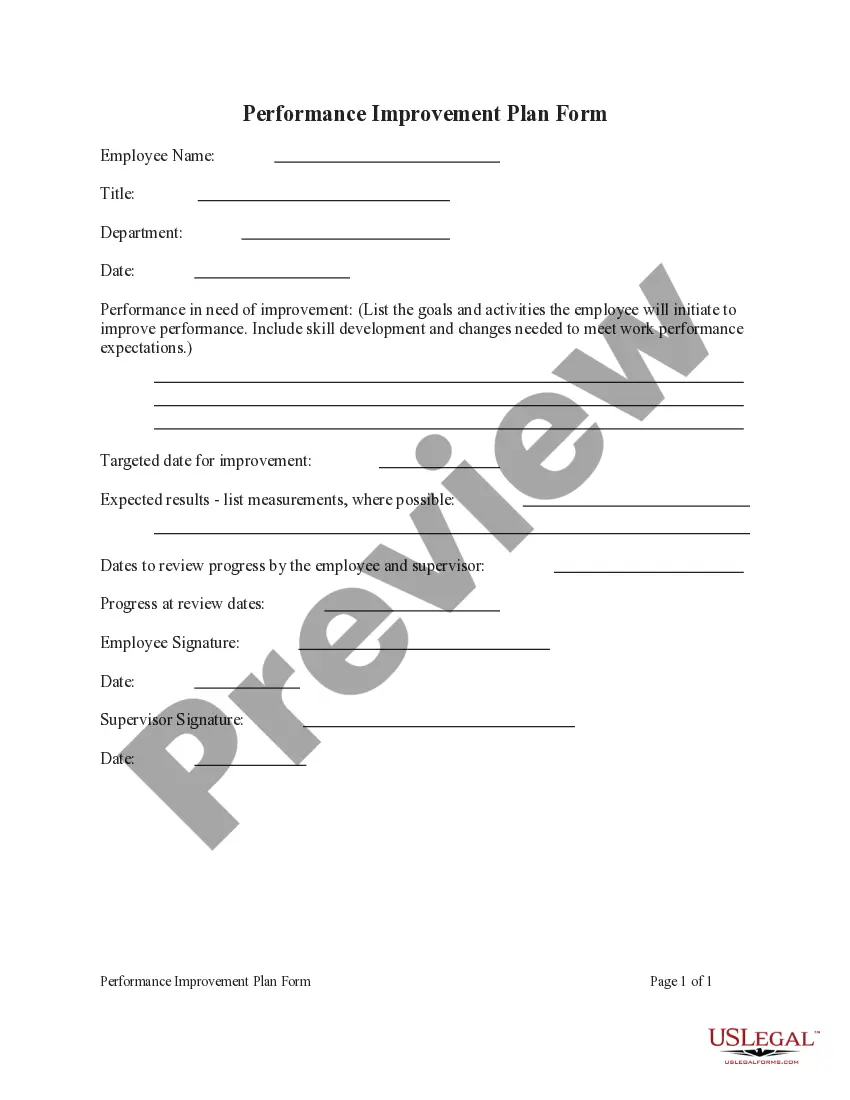

Simply put, maintenance performed on a regular basis to reduce the likelihood of failure is preventive maintenance. Also called planned or preventative maintenance, PM is conducted throughout an asset's normal operating conditions.

In order to build a most effective checklist that fits their enterprise, businesses should first:Delegate maintenance duties to relevant people.Set preventive maintenance program goals.Gether information about existing equipment.Shortlist equipment before including in the checklist.More items...?

For example: performing regular business and equipment inspections, cleaning and lubricating essential equipment, and tidying your business's grounds are all examples of preventive maintenance. The goal of preventive maintenance is to prevent equipment failure before it occurs, and to reduce the risk of accidents.

Maintenance checklists and logbooks are tools used by technicians to document equipment maintenance inspections. Equipment maintenance involves the continuous process of checking, repairing, and servicing operating equipment to ensure businesses can operate without interruption.

An effective preventative maintenance schedule avoids equipment failure, which can represent not only decreased productivity but also workplace safety risks to employees. In addition, a preventive maintenance checklist reduces human errors and contains important safety instructions that minimize the chance of injury.