Virginia Maintenance Assistance - Technician Checklist

Category:

State:

Multi-State

Control #:

US-380EM

Format:

Word;

Rich Text

Instant download

Description

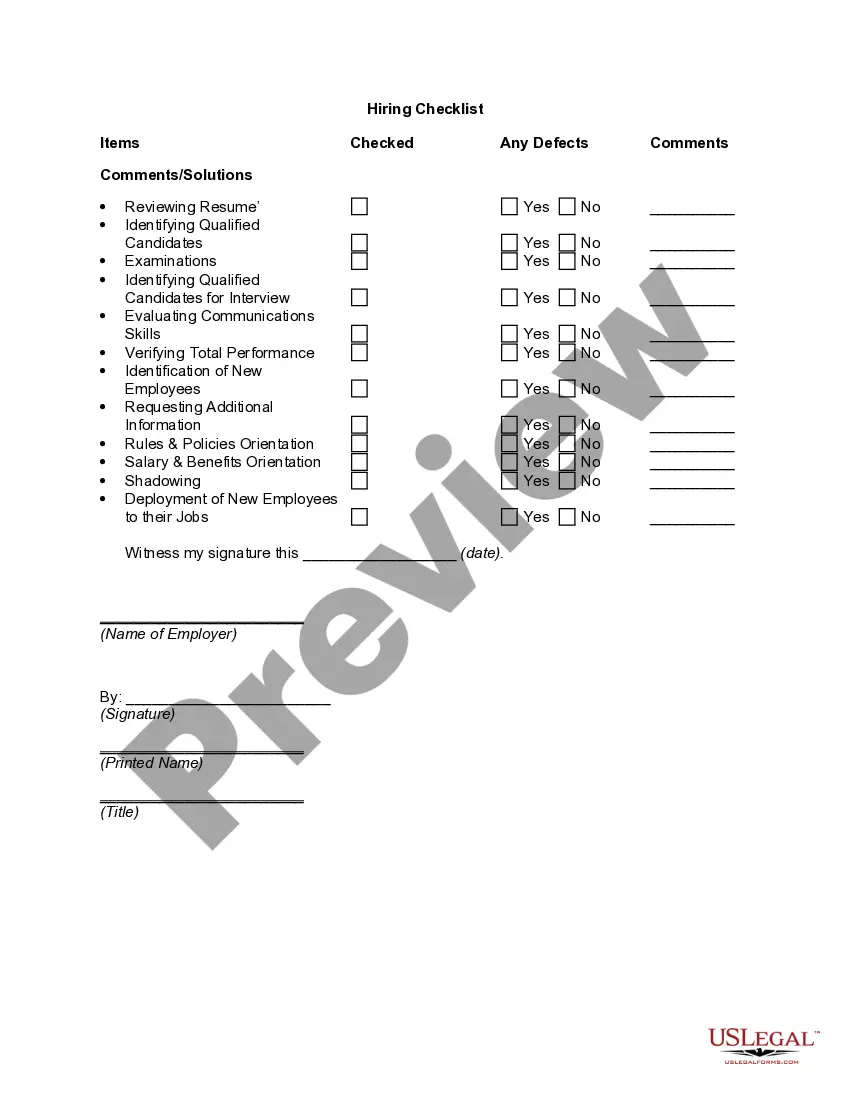

This form is used to list the potential duties of a maintenance assistant/technician.

How to fill out Maintenance Assistance - Technician Checklist?

It is feasible to allocate time online searching for the sanctioned document template that satisfies the federal and state requirements you need.

US Legal Forms offers thousands of legitimate forms that have been reviewed by experts.

You can easily download or print the Virginia Maintenance Assistance - Technician Checklist from my service.

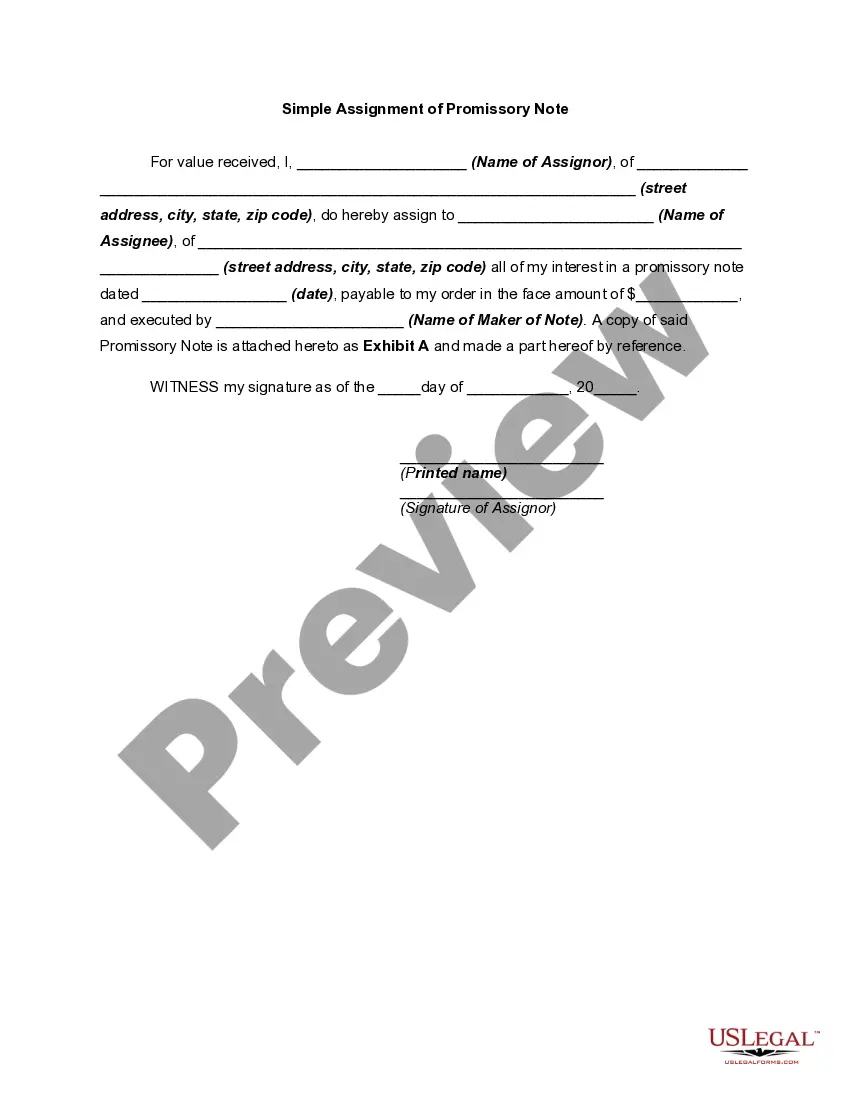

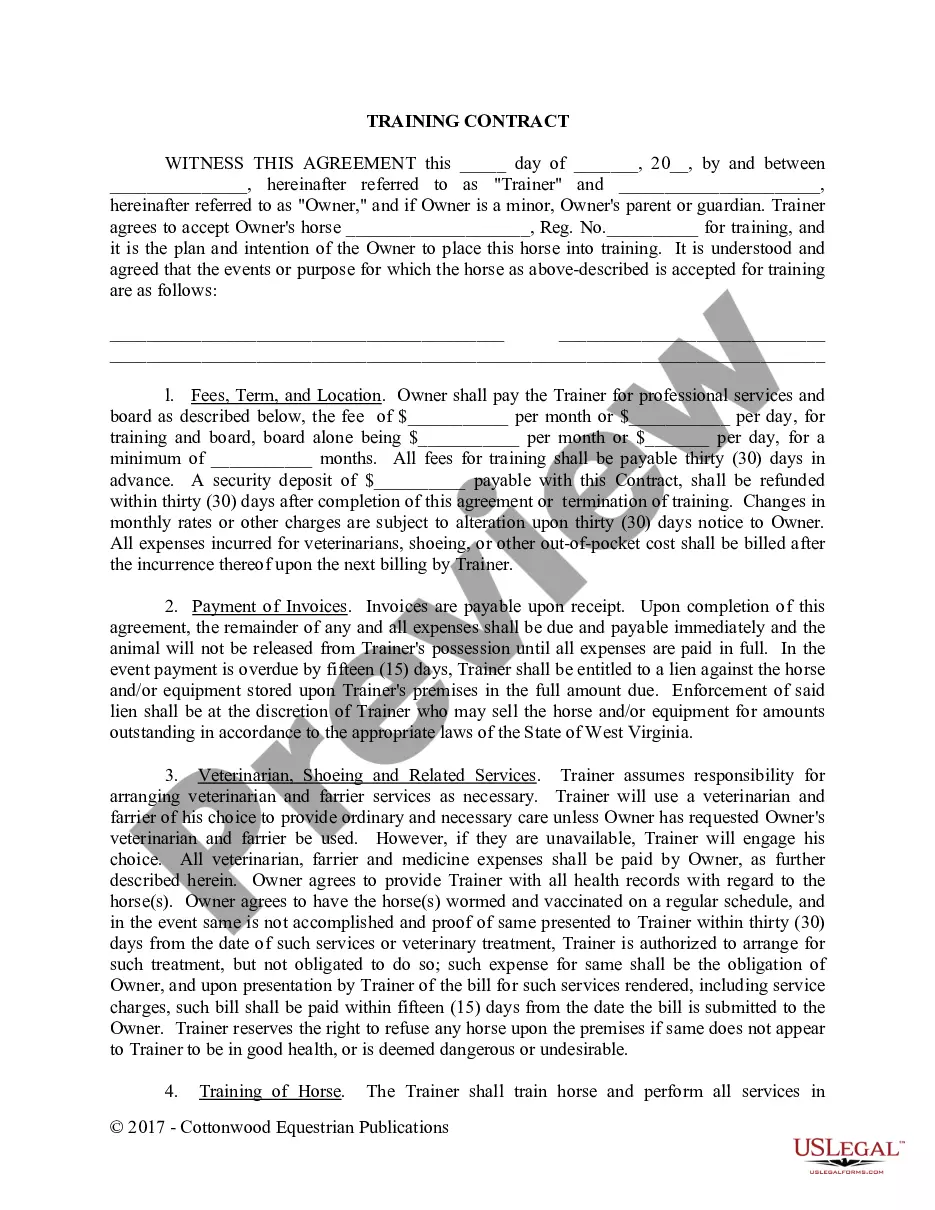

If available, utilize the Preview button to review the document template simultaneously.

- If you already have a US Legal Forms account, you can Log In and click the Download button.

- After that, you can fill out, modify, print, or sign the Virginia Maintenance Assistance - Technician Checklist.

- Each legal document template you obtain is yours permanently.

- To obtain another copy of a purchased form, go to the My documents section and click the corresponding button.

- If you are using the US Legal Forms website for the first time, follow the simple instructions below.

- First, ensure that you have selected the correct document template for your area/city that you select.

- Review the form description to make sure you have chosen the correct one.