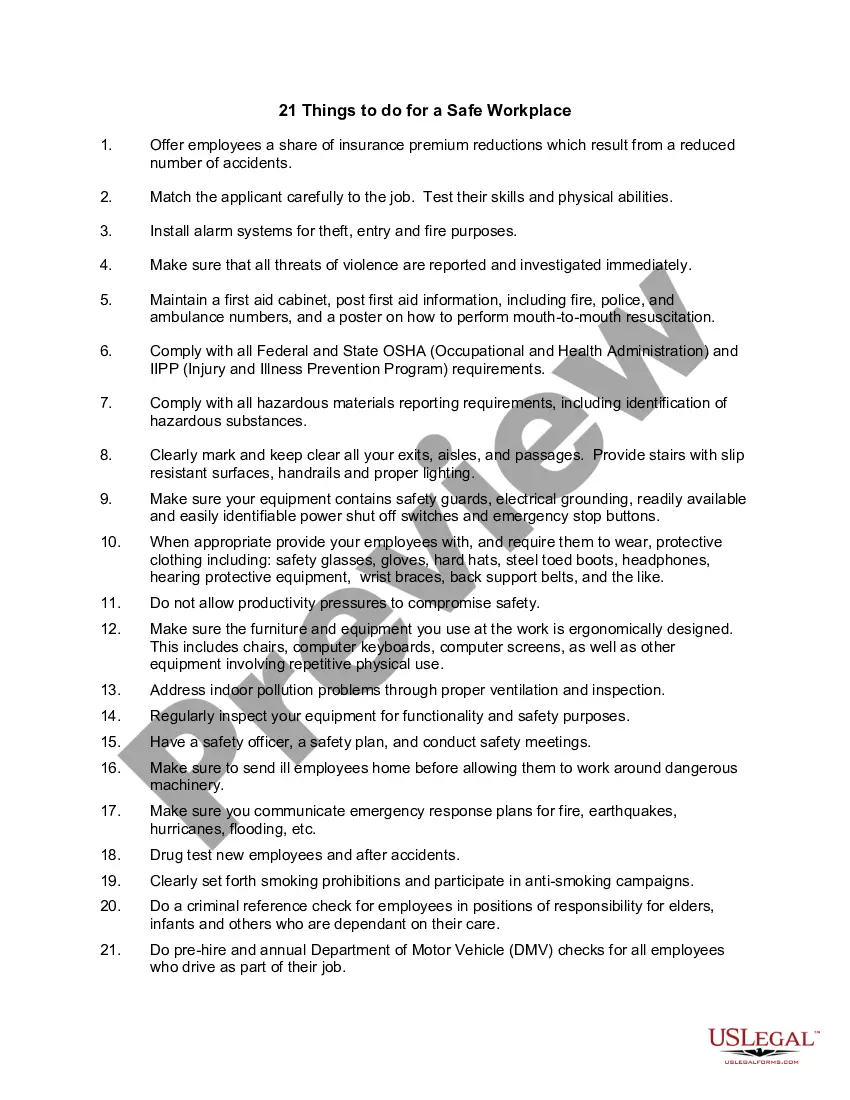

Vermont 21 Things to do for a Safe Workplace

Description

How to fill out 21 Things To Do For A Safe Workplace?

US Legal Forms - among the largest collections of legal documents in the USA - offers a range of legal document templates you can download or print.

By utilizing the site, you can find thousands of forms for business and personal purposes, organized by categories, states, or keywords.

You can access the most recent versions of forms such as the Vermont 21 Things to Do for a Safe Workplace in seconds.

Examine the form description to ensure you have selected the appropriate form.

If the form does not meet your needs, use the Search box at the top of the screen to find one that does.

- If you have an account, Log In and download Vermont 21 Things to Do for a Safe Workplace from your US Legal Forms library.

- The Download button will appear on each form you view.

- You can access all previously saved forms in the My documents section of your account.

- To use US Legal Forms for the first time, follow these simple steps to get started.

- Ensure you have selected the correct form for your municipality/region.

- Click the Preview button to review the form's content.

Form popularity

FAQ

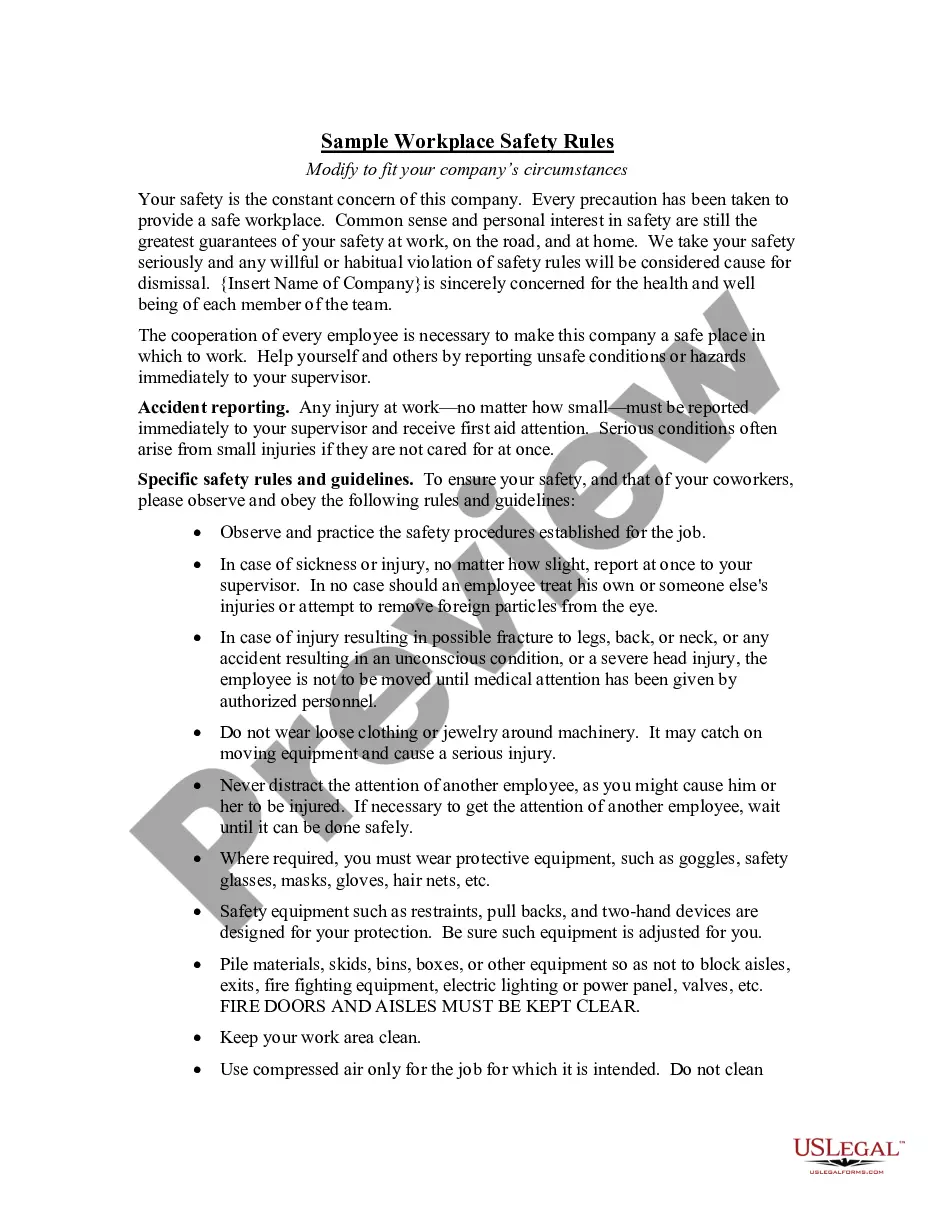

The duty of employers to provide a safe workplace is rooted in legal requirements and ethical obligations. Employers must create an environment where employees feel secure in performing their tasks without fear of injury. This aligns directly with the Vermont 21 Things to do for a Safe Workplace, which outlines essential practices for improving safety. By committing to these standards, employers promote workplace safety and employee well-being.

Employers have a primary responsibility to ensure that their workplace is safe for all employees. This includes identifying potential hazards, providing necessary training, and implementing safety protocols. By following the Vermont 21 Things to do for a Safe Workplace, employers can reduce risks and create a proactive culture around safety. Regular assessments and updates are vital for maintaining a safe environment.

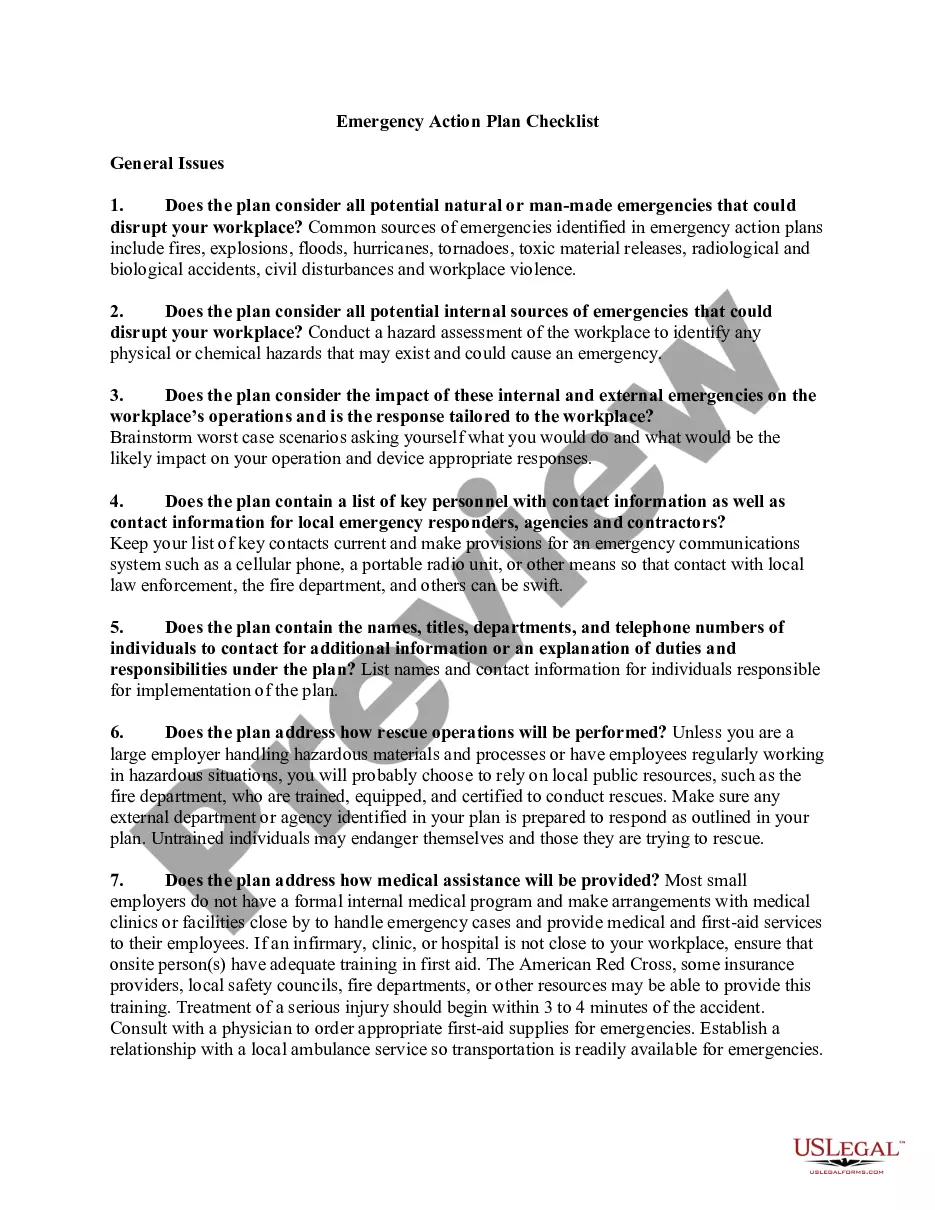

An OSHA 7 form is used to report workplace injuries and illnesses. This documentation helps employers and OSHA monitor safety trends and address potential concerns. Utilizing the information on OSHA 7 forms can complement your efforts in applying Vermont 21 Things to Do for a Safe Workplace.

OSHA's safety guidelines focus on preventing workplace hazards and protecting employees' health. These guidelines include proper training programs, adequate maintenance of equipment, and clearly communicating safety protocols. Implementing the Vermont 21 Things to Do for a Safe Workplace will help you align with OSHA’s standards.

Ten basic safety rules include following all safety signage, using personal protective equipment, reporting unsafe conditions immediately, and keeping work areas clean and organized. Encouraging a culture of safety among employees supports compliance with these rules. By applying Vermont 21 Things to Do for a Safe Workplace, you can create a more secure environment.

OSHA recommends following seven general guidelines for workplace safety, including proper hazard communication, maintaining clean work environments, and ensuring proper use of personal protective equipment. It's important to actively involve employees in safety training and encourage reporting of unsafe conditions. When combined, these guidelines contribute to achieving Vermont 21 Things to Do for a Safe Workplace.

To ensure a safe work area, start by conducting regular safety audits and risk assessments. Training employees about safety procedures and providing necessary safety equipment is also crucial. Implementing the Vermont 21 Things to Do for a Safe Workplace can guide you to enhance safety measures effectively.

The Occupational Safety and Health Administration (OSHA) has established many guidelines to ensure workplace safety. These cover various aspects of workplace health and safety across different industries. It's essential to familiarize yourself with OSHA's guidelines to implement Vermont 21 Things to Do for a Safe Workplace effectively.

The Occupational Safety and Health Administration (OSHA) keeps employees safe by setting and enforcing workplace safety standards. These standards cover a wide range of industries and include guidelines on equipment use, hazard communication, and emergency preparedness. OSHA also conducts inspections and provides training resources to help employers implement best practices. Exploring the Vermont 21 things to do for a safe workplace can enhance your understanding of these standards and promote a culture of safety.

Employers are legally required to provide a safe workplace under the Occupational Safety and Health Act. This includes ensuring that employees are not exposed to hazardous conditions that can harm their health or safety. In addition, state regulations in Vermont outline specific safety measures employers must implement. Familiarizing yourself with the Vermont 21 things to do for a safe workplace can help maintain compliance and foster a secure environment for all.