Vermont Toll Manufacturing Agreement

Description

How to fill out Toll Manufacturing Agreement?

If you need to finalize, acquire, or generate authentic document templates, utilize US Legal Forms, the foremost collection of legal documents available online.

Employ the site’s straightforward and user-friendly search function to locate the documents you seek. Numerous templates for both business and personal use are categorized by types and states, or keywords.

Utilize US Legal Forms to find the Vermont Toll Manufacturing Agreement in just a few clicks.

Each legal document format you purchase is yours permanently. You have access to every document you acquired with your account. Click on the My documents section and select a document to print or download again.

Complete and download, and print the Vermont Toll Manufacturing Agreement with US Legal Forms. There are thousands of professional and state-specific forms you can utilize for your business or personal needs.

- If you are already a US Legal Forms user, Log In to your account and click on the Download option to locate the Vermont Toll Manufacturing Agreement.

- You can also access documents you previously downloaded from the My documents section of your account.

- If you are using US Legal Forms for the first time, refer to the instructions below.

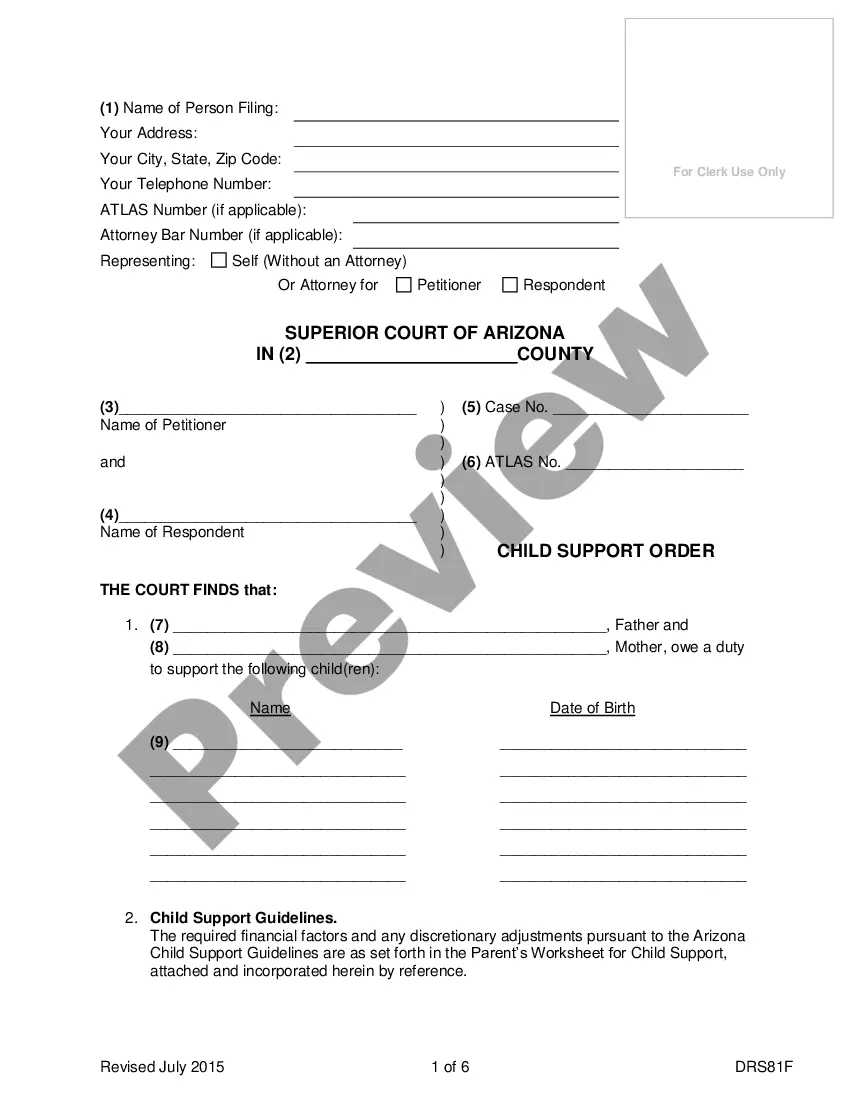

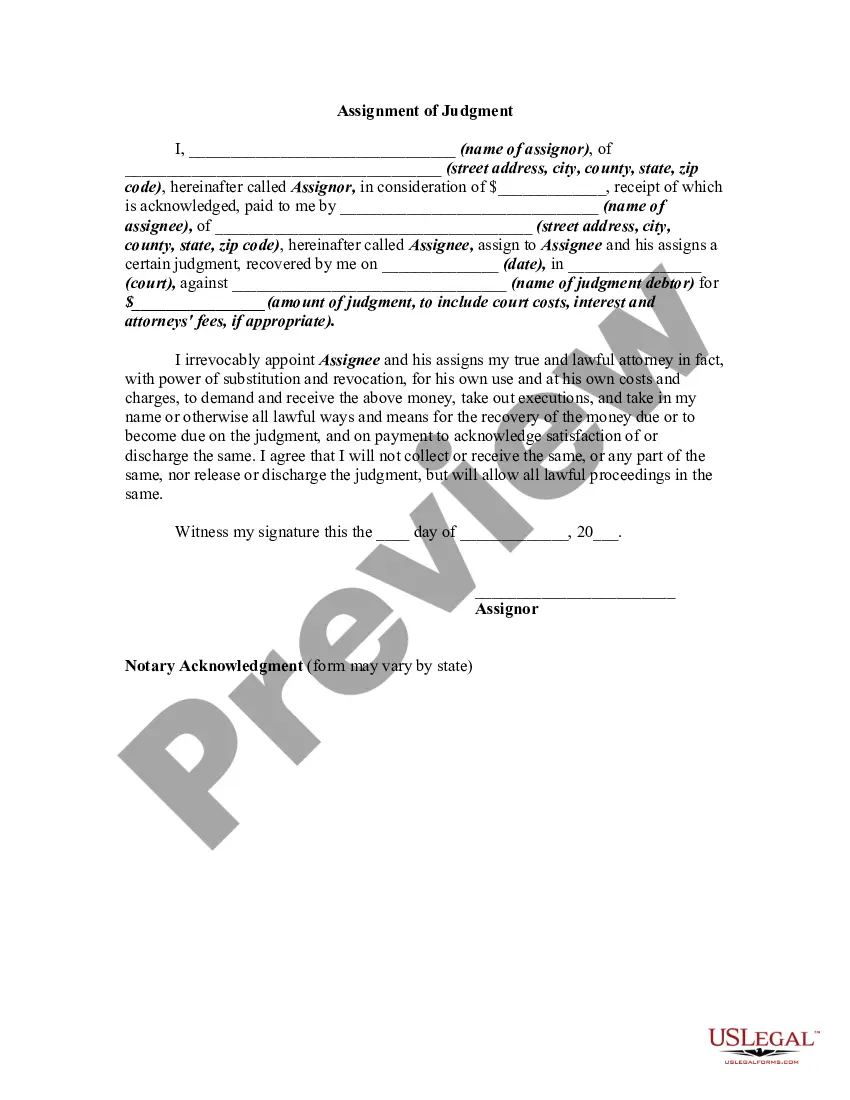

- Step 1. Ensure you have selected the form for the correct city/state.

- Step 2. Use the Preview option to review the form’s content. Don’t forget to check the details.

- Step 3. If you are not satisfied with the document, utilize the Search area at the top of the screen to find alternative versions in the legal document format.

- Step 4. Once you have located the form you want, click on the Get now option. Choose the pricing plan you prefer and enter your details to register for an account.

- Step 5. Process the transaction. You can use your Visa or Mastercard or PayPal account to complete the transaction.

- Step 6. Select the format of the legal document and download it to your device.

- Step 7. Complete, modify, and print or sign the Vermont Toll Manufacturing Agreement.

Form popularity

FAQ

A toll manufacturing arrangement is a contractual agreement whereby one company provides manufacturing services for another using materials supplied by the client. This setup often includes detailed specifications for production and quality standards, outlined in a Vermont Toll Manufacturing Agreement. Companies benefit from reduced costs and increased production capacity without the burden of owning manufacturing facilities.

A traditional manufacturer produces goods using their own materials and resources, while a toll manufacturer processes products using materials supplied by a client. The key distinction lies in ownership; in a Vermont Toll Manufacturing Agreement, the client retains ownership of the materials, minimizing risk and capital investment. This creates a synergistic partnership, as toll manufacturers focus solely on production.

Toll manufacturing in SAP involves a third-party manufacturer processing raw materials provided by a client. This arrangement allows clients to leverage external manufacturing capabilities without investing in their own facilities. In the context of a Vermont Toll Manufacturing Agreement, companies gain flexibility and efficiency, ensuring their products meet market demands while maintaining control over raw materials.

Toll manufacturing entails the client retaining ownership of the materials and products during production, as specified in the Vermont Toll Manufacturing Agreement, while contract manufacturing involves the manufacturer owning both the process and the final products. This fundamental difference can impact costs, quality control, and turnaround time. Understanding these distinctions can help businesses choose the right manufacturing solution for their needs.

The opposite of toll manufacturing is often considered to be contract manufacturing, where the manufacturer takes ownership of the production process and the finished product. Unlike in a Vermont Toll Manufacturing Agreement, the client relinquishes control over the materials and production methods. This difference influences business decisions based on factors like risk, quality control, and investment needs.

Contract manufacturing refers to an arrangement where one company produces goods for another under a contractual agreement. In contrast to toll manufacturing, the manufacturer usually owns the production process and may also manage the supply chain. Clients may choose contract manufacturing to benefit from the manufacturer’s existing facilities and expertise while outsourcing production.

In a toll manufacturing arrangement, the principal is typically the client who owns the materials and the final product. The Vermont Toll Manufacturing Agreement clearly defines the roles, ensuring the toll manufacturer operates under the client's guidelines and specifications. This relationship allows the client to focus on their core business while the toll manufacturer handles the production efforts.

The toll manufacturing process involves a client providing raw materials to a toll manufacturer, who then processes these materials into finished products. Under the Vermont Toll Manufacturing Agreement, the manufacturer uses the client’s specifications to produce the goods, often employing specialized techniques or equipment. This process streamlines production without the client needing to invest in expensive manufacturing facilities.

The Vermont Toll Manufacturing Agreement outlines the terms under which one company (the 'toll manufacturer') produces goods on behalf of another company (the 'client'). In contract manufacturing, the manufacturer owns the production process, while in toll manufacturing, the client retains ownership of the materials and the end product. This distinction allows for more flexibility and control over production for the client.

Contract manufacturing involves a company hiring another to produce goods on its behalf, often including design and production. Conversely, toll manufacturing, as described in a Vermont Toll Manufacturing Agreement, focuses on the processing of materials owned by one party, with the manufacturer charging for the labor involved in transforming those materials into finished products. This distinction allows companies to maximize their resources effectively.