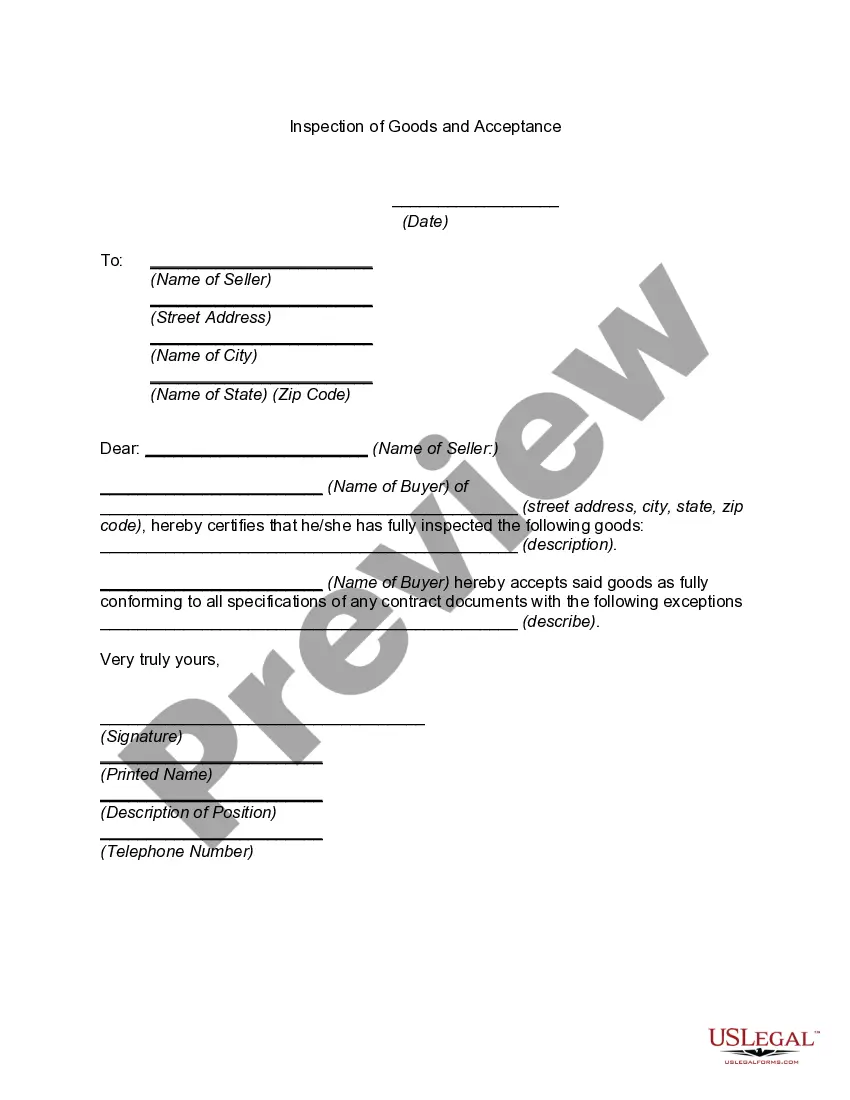

Vermont Inspection of Goods and Acceptance is a crucial process that ensures the quality and condition of goods received by buyers in the state of Vermont. This inspection is carried out to confirm if the goods received meet the agreed-upon specifications, standards, and other contractual requirements. It serves as a protective measure for buyers against receiving defective or non-compliant goods. During the Vermont Inspection of Goods and Acceptance, the buyer, or their authorized representative, thoroughly examines the received goods to assess their quality, quantity, functionality, and conformity to the purchase agreement. This inspection typically occurs before the acceptance and payment of goods, preventing buyers from being obligated to accept unsatisfactory products. The objective of this inspection is to verify that the goods received are free from defects, damage, and non-compliance with the agreed-upon terms. It typically includes a comprehensive evaluation of various aspects such as packaging, labeling, documentation, appearance, performance, and functionality. Any discrepancies identified during the inspection are documented and reported to the supplier, allowing the buyer to negotiate reparations, replacements, or refunds. There are different types of Vermont Inspection of Goods and Acceptance, each serving specific purposes: 1. Incoming Goods Inspection: This type of inspection is performed upon the receipt of goods from the supplier or manufacturer. It ensures that the goods match the order specifications, quality standards, and are in good condition. 2. In-process Inspection: This type of inspection is conducted during the manufacturing or assembly process to identify any defects or non-compliance at an early stage. It helps to prevent the production of faulty goods and allows for timely corrective actions. 3. Final Goods Inspection: This inspection occurs when the goods are completed and ready for shipment. It verifies if the goods meet all the agreed-upon requirements, including quality, quantity, labeling, packaging, and documentation. 4. Sampling Inspection: In certain cases, a representative sample of goods is inspected instead of examining each individual unit. This method is used for large quantities or when time or resources are limited. The sample is chosen to use statistical methods to determine its representativeness and reliability. Vermont Inspection of Goods and Acceptance plays a vital role in protecting buyers' interests by ensuring the received goods are of satisfactory quality and comply with the contractual agreements. It helps buyers avoid financial losses, minimize potential disputes, and maintain a positive supplier-buyer relationship. Conducting thorough inspections is essential for maintaining trust, quality assurance, and overall customer satisfaction in the Vermont business community.

Vermont Inspection of Goods and Acceptance

Description

How to fill out Vermont Inspection Of Goods And Acceptance?

US Legal Forms - one of several greatest libraries of lawful types in the United States - offers a wide array of lawful record web templates you can down load or printing. Using the website, you may get thousands of types for organization and person functions, categorized by classes, claims, or keywords and phrases.You can get the most recent versions of types such as the Vermont Inspection of Goods and Acceptance within minutes.

If you have a registration, log in and down load Vermont Inspection of Goods and Acceptance from your US Legal Forms local library. The Download option can look on every develop you view. You get access to all earlier delivered electronically types in the My Forms tab of your respective account.

If you want to use US Legal Forms the first time, listed here are straightforward directions to help you get started:

- Be sure you have picked the proper develop to your city/area. Go through the Preview option to analyze the form`s content. Browse the develop explanation to actually have chosen the appropriate develop.

- When the develop doesn`t fit your demands, make use of the Look for discipline at the top of the screen to find the the one that does.

- When you are content with the shape, confirm your selection by clicking the Purchase now option. Then, opt for the costs prepare you favor and provide your accreditations to register for an account.

- Process the deal. Make use of your charge card or PayPal account to complete the deal.

- Find the file format and down load the shape on the product.

- Make modifications. Fill out, modify and printing and indication the delivered electronically Vermont Inspection of Goods and Acceptance.

Each format you put into your account does not have an expiration day and is yours for a long time. So, if you wish to down load or printing yet another duplicate, just check out the My Forms section and click on around the develop you need.

Get access to the Vermont Inspection of Goods and Acceptance with US Legal Forms, one of the most comprehensive local library of lawful record web templates. Use thousands of skilled and condition-certain web templates that fulfill your organization or person requirements and demands.

Form popularity

FAQ

Vermont has required safety inspections on vehicles since 1935 and inspection procedures became Administrative Rules in the 1960s. Emissions inspections have been required since 1997.

The new Vermont State Inspection is active now.Brakes and exhaust must be in good shape.Front windows and all external lights must work.There must be no dash light (like a check engine light)The tires must have good tread and the suspension elements must be functioning properly.More items...

Customers can take vehicles in for inspection up to two months before the inspection is due. Customers need to work with their mechanic/dealer to get vehicle repaired as soon as possible. Always carry the Vehicle Inspection Report (VIR) in the vehicle, showing that you are working towards compliance.

The results are recorded, and the scan tool is disconnected from the vehicle. The entire OBD check typically takes less than 5 minutes.

200b200bVIP's Certified Automotive Professionals will perform your Vermont State Inspection 7 days a week. The cost is $49.99 per vehicle per year.

A person shall be subject to a civil penalty of not more than $5.00, which penalty shall be exempt from surcharges under 13 V.S.A. § 7282(a), if he or she is cited for a violation of this section within the 14 days following expiration of the motor vehicle inspection sticker.

MONTPELIER In response to the COVID-19 pandemic, the Vermont Dept. of Motor Vehicles (DMV) has been instructed to extend motor vehicle inspections due in April another 60 days and has launched a program for renewing licenses online.

(c) A person shall not operate a motor vehicle unless it has been inspected as required by this section and has a valid certification of inspection affixed to it. A person shall be subject to a civil penalty of not more than $5.00, which penalty shall be exempt from surcharges under 13 V.S.A.

Customers can take vehicles in for inspection up to two months before the inspection is due. Customers need to work with their mechanic/dealer to get vehicle repaired as soon as possible. Always carry the Vehicle Inspection Report (VIR) in the vehicle, showing that you are working towards compliance.