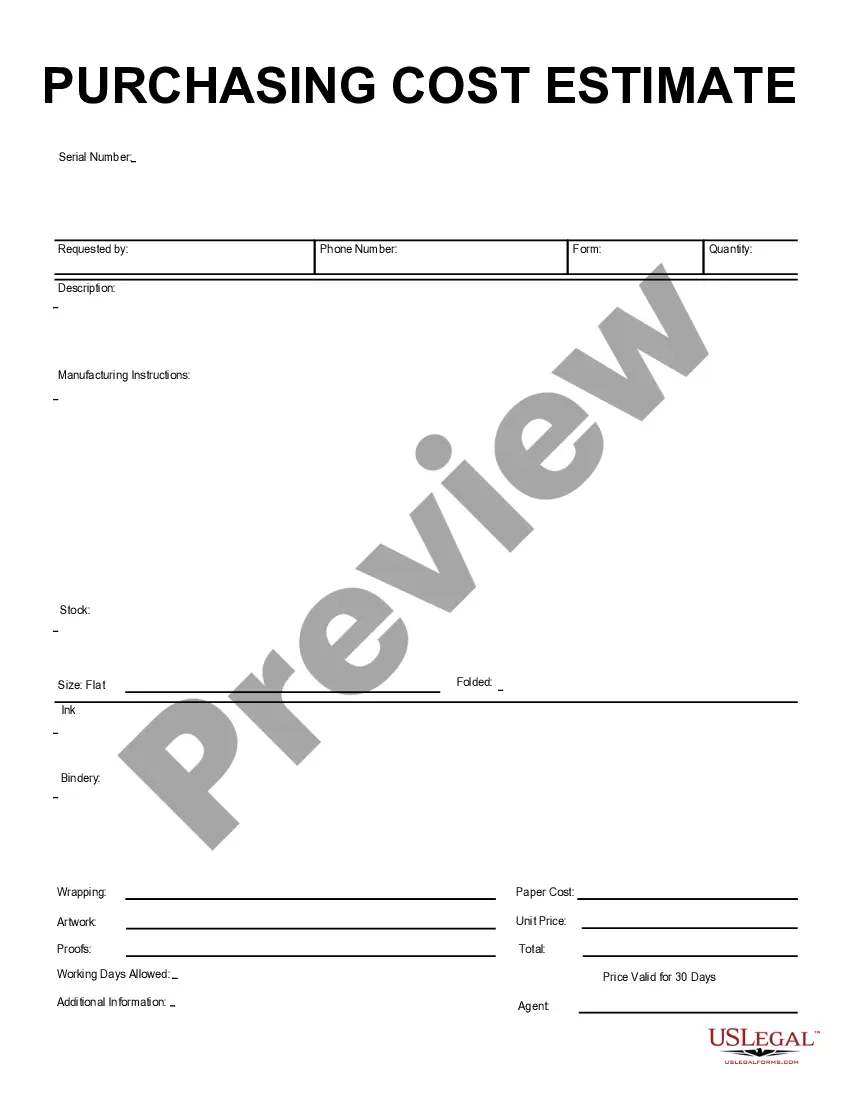

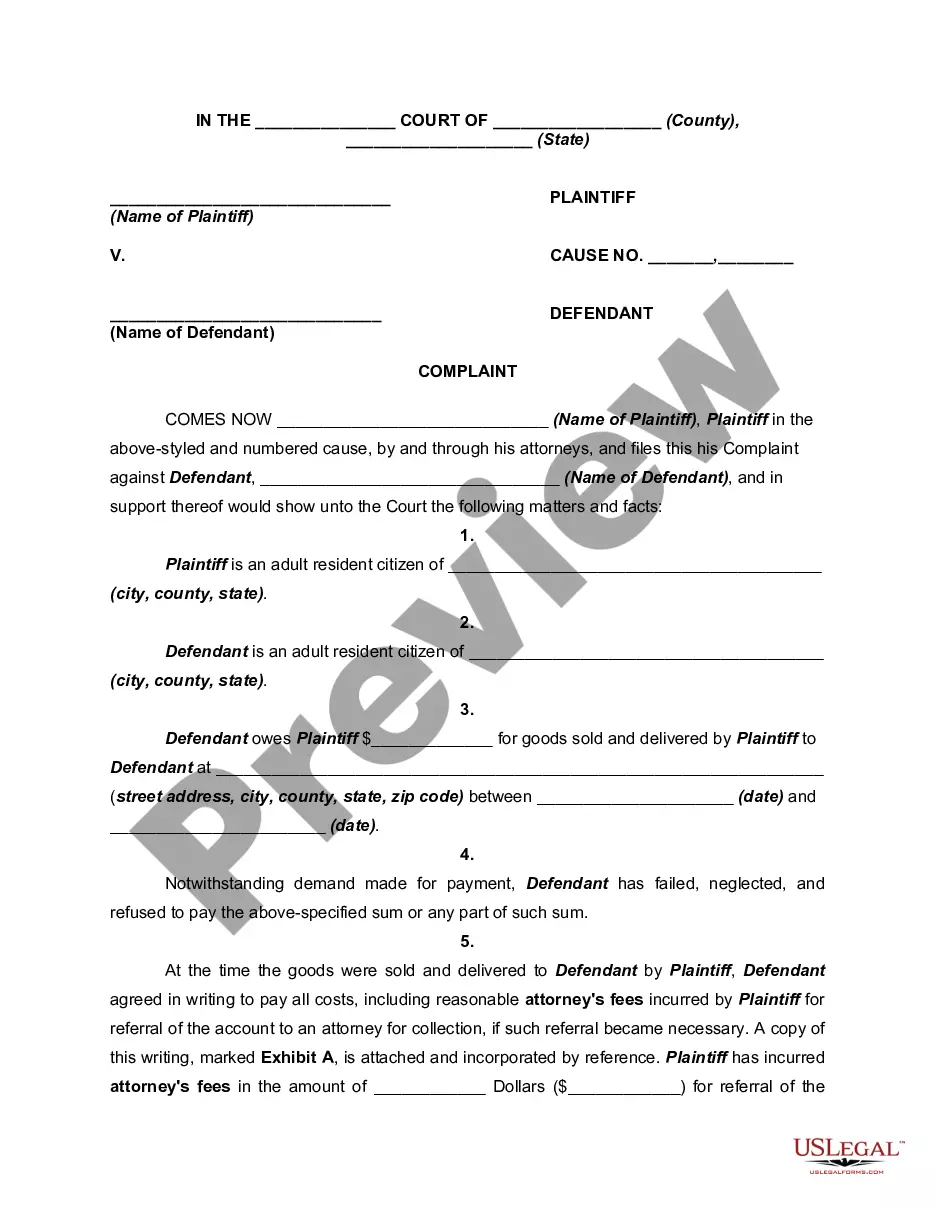

This is a tooling agreement between the buyer and vendor. The document describes the description of tooling, the replacement value of tooling, location of tooling, and the relationship of the parties in all their dealings.

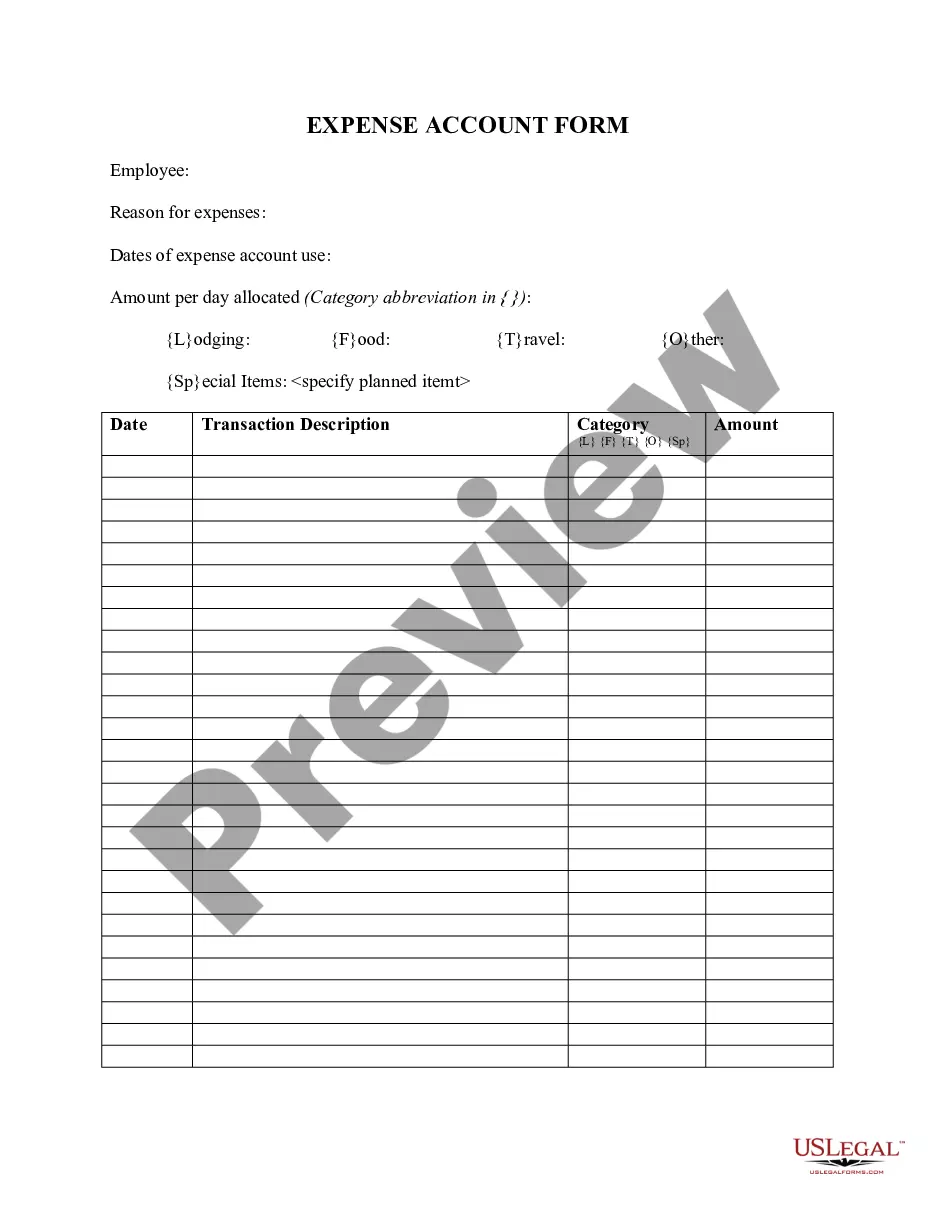

Vermont Tooling Agreement

Description

How to fill out Tooling Agreement?

Choosing the right legitimate document format might be a battle. Naturally, there are tons of web templates available on the Internet, but how can you discover the legitimate type you need? Make use of the US Legal Forms website. The services provides a large number of web templates, such as the Vermont Tooling Agreement, which you can use for organization and personal requirements. All of the forms are inspected by experts and fulfill state and federal demands.

Should you be currently signed up, log in in your profile and click the Down load option to obtain the Vermont Tooling Agreement. Use your profile to check throughout the legitimate forms you might have ordered in the past. Check out the My Forms tab of your own profile and acquire yet another version of your document you need.

Should you be a brand new end user of US Legal Forms, listed below are straightforward instructions for you to stick to:

- Initially, make sure you have selected the appropriate type for the city/region. It is possible to look over the form while using Review option and look at the form information to ensure it will be the best for you.

- If the type will not fulfill your expectations, utilize the Seach discipline to obtain the appropriate type.

- When you are sure that the form is suitable, select the Purchase now option to obtain the type.

- Choose the prices prepare you need and enter in the needed details. Make your profile and buy the order making use of your PayPal profile or bank card.

- Opt for the submit file format and down load the legitimate document format in your device.

- Total, change and printing and sign the obtained Vermont Tooling Agreement.

US Legal Forms is the biggest library of legitimate forms for which you can discover various document web templates. Make use of the company to down load skillfully-made papers that stick to state demands.

Form popularity

FAQ

(2) In order to be able to manufacture the Products, Supplier will need specific Production Equipment. For that purpose, this Tooling Agreement stipulates the rights and duties of the Parties with regard to the ownership, utilization and maintenance of such Production Equipment.