Washington Know Your Lockout Ragout (LOT) Safety Procedures are designed to protect workers from hazardous energy sources found in industrial and manufacturing settings. These safety procedures are based on the Occupational Safety and Health Administration (OSHA) standards for controlling hazardous energy. These procedures are intended to help employers and employees understand their responsibilities for controlling hazardous energy and to provide guidance for implementing a successful Lockout Ragout program. Washington Know Your Lockout Ragout Safety Procedures involve the identification, isolation, and control of hazardous energy sources. Lockout is the process of placing a physical barrier on a machine or piece of equipment to prevent the accidental activation or release of hazardous energy. Ragout is the process of attaching a warning label to a machine or piece of equipment to alert employees of the presence of hazardous energy. The main types of Washington Know Your Lockout Ragout Safety Procedures are the following: • Establishing a LockouRagoutut Program: This involves identifying and evaluating hazardous energy sources, creating a written program, and training employees on how to properly lock and tag out machines and equipment. • Isolating Hazardous Energy Sources: This involves learning how to identify and isolate hazardous energy sources, and understanding the proper steps to follow when isolating energy sources. • Performing LockouRagoutut Procedures: This involves understanding the process of locking and tagging out machines and equipment, and knowing how to safely perform lockout/ragout procedures. • Maintenance and Inspection of LockouRagoutut Devices: This involves understanding the proper maintenance and inspection of lockout/ragout devices, and learning how to properly inspect and repair lockout/ragout devices. • Releasing Locked and Tagged Out Machines and Equipment: This involves understanding how to safely release locked and tagged out machines and equipment, and knowing how to properly document the process.

Washington Know Your Lockout Tagout Safety Procedures

Description

How to fill out Washington Know Your Lockout Tagout Safety Procedures?

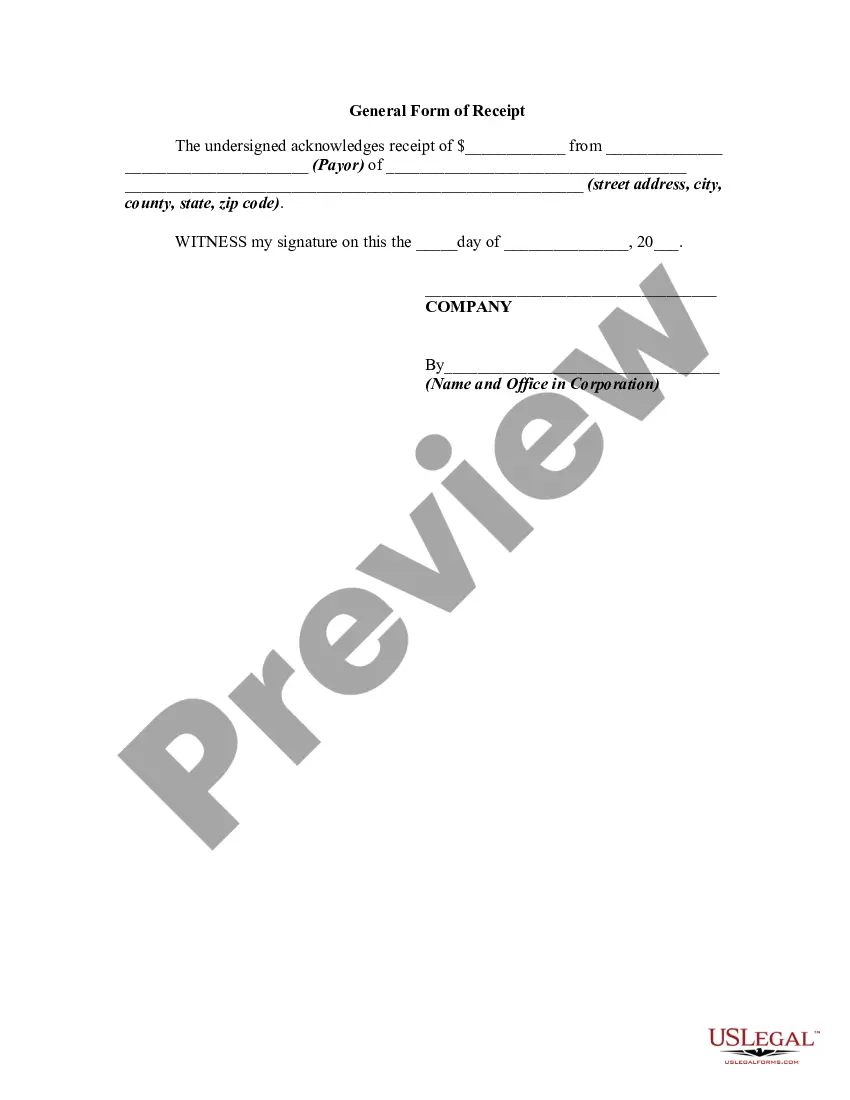

Working with legal paperwork requires attention, accuracy, and using well-drafted templates. US Legal Forms has been helping people across the country do just that for 25 years, so when you pick your Washington Know Your Lockout Tagout Safety Procedures template from our service, you can be sure it meets federal and state regulations.

Dealing with our service is simple and quick. To get the required paperwork, all you’ll need is an account with a valid subscription. Here’s a quick guideline for you to get your Washington Know Your Lockout Tagout Safety Procedures within minutes:

- Remember to carefully check the form content and its correspondence with general and legal requirements by previewing it or reading its description.

- Search for an alternative formal blank if the previously opened one doesn’t match your situation or state regulations (the tab for that is on the top page corner).

- Log in to your account and save the Washington Know Your Lockout Tagout Safety Procedures in the format you prefer. If it’s your first time with our service, click Buy now to proceed.

- Register for an account, decide on your subscription plan, and pay with your credit card or PayPal account.

- Choose in what format you want to save your form and click Download. Print the blank or upload it to a professional PDF editor to prepare it electronically.

All documents are drafted for multi-usage, like the Washington Know Your Lockout Tagout Safety Procedures you see on this page. If you need them one more time, you can fill them out without re-payment - just open the My Forms tab in your profile and complete your document any time you need it. Try US Legal Forms and accomplish your business and personal paperwork quickly and in total legal compliance!

Form popularity

FAQ

LOTO Safety: 7 Steps of lockout tagout Prepare for shutdown. Notify all affected employees of the activities and equipment involved. Shut down the equipment. Isolate the equipment from the hazardous energy source. Dissipate residual energy. Apply applicable lockout or tagout devices.

A lockout/tagout procedure should include the following six steps: Preparation. Shutdown. Isolation. Lockout/tagout. Stored energy check. Isolation verification.

Affected employees must be notified before lockout/tagout operations are begun and informed which machines or equipment will be shut down and locked out. All other employees who work in the area of the lock-out must be able to recognize when a lock-out procedure is in progress.

8 Steps of a lockout tagout procedure STEP 1: Notify affected employees.STEP 2: Identify procedure and hazards.STEP 3: Shut down.STEP 4: Isolate machine from energy source.STEP 5: Apply lockout tagout devices.STEP 6: Check stored energy.STEP 7: Verify isolation.STEP 8: Bring equipment back on line.

(1) Notify all affected employees that servicing or maintenance is required on a machine or equipment and that the machine or equipment must be shut down and locked out to perform the servicing or maintenance.

8 Steps of a lockout tagout procedure STEP 1: Notify affected employees.STEP 2: Identify procedure and hazards.STEP 3: Shut down.STEP 4: Isolate machine from energy source.STEP 5: Apply lockout tagout devices.STEP 6: Check stored energy.STEP 7: Verify isolation.STEP 8: Bring equipment back on line.

In addition, all affected employees must be notified that the lockout or tagout devices have been removed before the equipment is started 29 CFR 1910.147(e)(2)(i)-29 CFR 1910.147(e)(2)(ii).

This standard requires on-site employers and outside employers to inform each other of their respective lockout/tagout procedures. Furthermore, an on-site employer is required to ensure that his personnel understand and comply with restrictions and prohibitions of the outside employer's energy control procedures.