Washington Aeseptic Techniques

Description

How to fill out Aeseptic Techniques?

You might spend hours online attempting to locate the legal document format that satisfies your state and federal requirements.

US Legal Forms provides thousands of legal templates that have been reviewed by professionals.

It's easy to obtain or create the Washington Aseptic Techniques through our service.

If available, utilize the Review button to browse the document format as well.

- If you possess a US Legal Forms account, you can sign in and press the Download button.

- Subsequently, you can fill out, alter, create, or sign the Washington Aseptic Techniques.

- Every legal document format you purchase is yours indefinitely.

- To obtain an additional copy of any purchased form, navigate to the My documents tab and click the appropriate button.

- If this is your first time using the US Legal Forms website, follow the straightforward instructions below.

- First, ensure you have chosen the correct format for your location.

- Review the form description to confirm you've selected the appropriate document.

Form popularity

FAQ

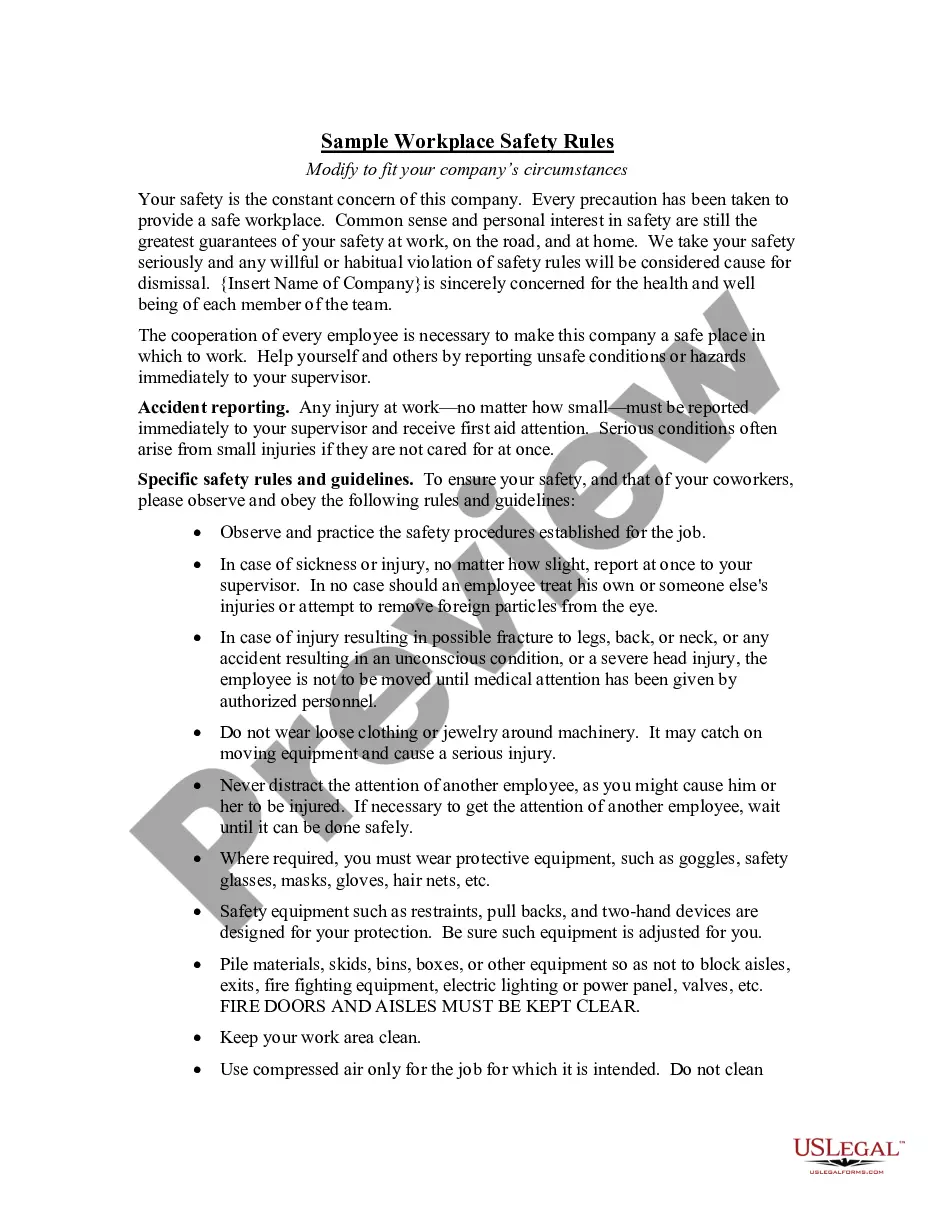

Procedures such as surgeries, injections, and drainage of abscesses all require the use of aseptic techniques. These practices adhere to Washington Aseptic Techniques, ensuring that all instruments and environments are sterile. Understanding which procedures require these techniques is fundamental for healthcare workers. Always prioritize aseptic practices to safeguard patient health.

Aseptic technique is a collection of medical practices and procedures that helps protect patients from dangerous germs. Bacteria, viruses, and microorganisms are everywhere, so using aseptic technique can help keep important equipment from being contaminated.

Aseptic techniques include:Wiping bench with disinfectant/alcohol. Not growing microorganisms at body temperature. Using sterile loops when transferring cultures . Flaming culture bottle necks to prevent contamination. Sterilising (using an autoclave ) or disposing of all used equipment.

Aseptic technique is classified into two different categories: standard aseptic technique and surgical aseptic technique.

PRINCIPLES OF THE ASEPTIC TECHNIQUECreating a microorganism-free environment (sterile field)Use of sterilized instruments and dressings.Maintaining sterility of sterile field and instruments by preventing microbial contaminationby contact with non-sterile objects; such as:More items...

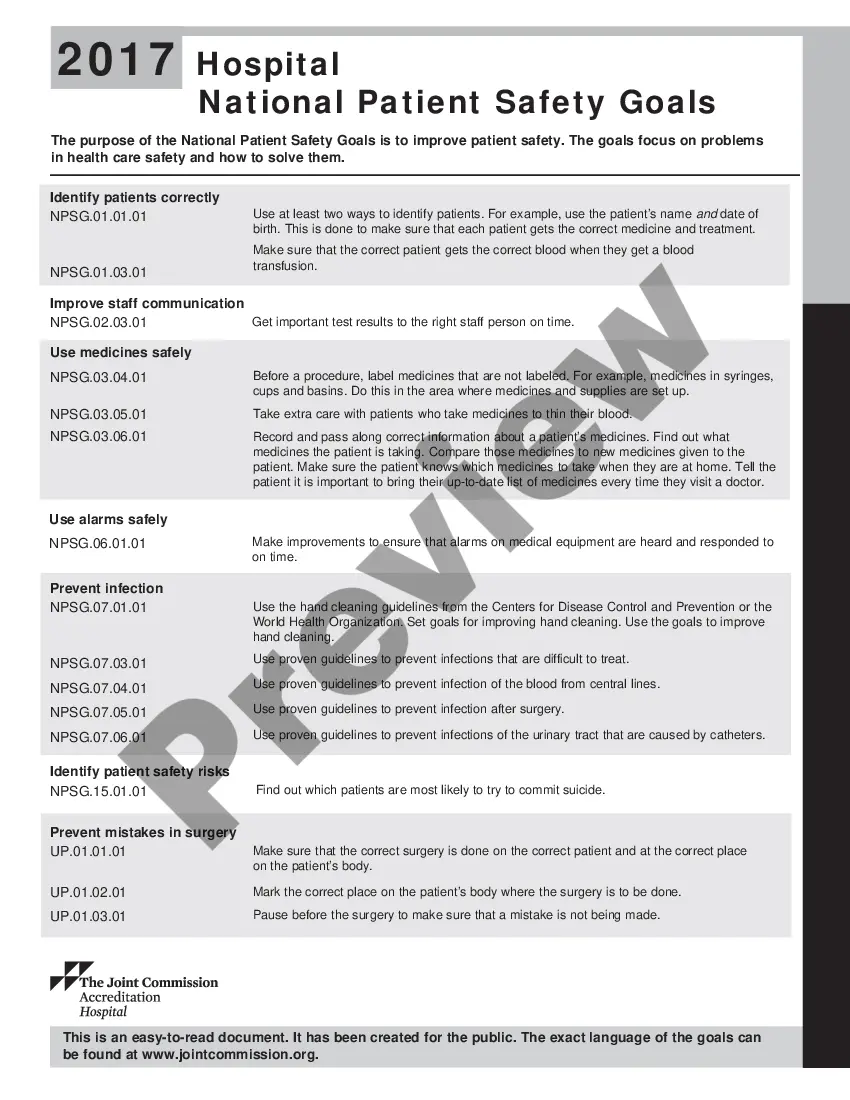

According to The Joint Commission, there are four chief aspects of the aseptic technique: barriers, patient equipment and preparation, environmental controls, and contact guidelines. Each plays an important role in infection prevention during a medical procedure.

These principles include the following: (1) use only sterile items within a sterile field; (2) sterile (scrubbed) personnel are gowned and gloved; (3) sterile personnel operate within a sterile field (sterile personnel touch only sterile items or areas, unsterile personnel touch only unsterile items or areas); (4)

Procedures that involve aseptic technique include:200cInserting PICC lines.200cPerforming dialysis.200cInserting catheters.200cRunning IVs.200cInserting chest tubes.200cPerforming surgeries.200cDressing wounds.

Principles of Sterile TechniqueFace to face or back to back.Turn back to a non-sterile person or when passing.Face a sterile area when passing the area.Ask a non-sterile person to step aside rather than trying to crowd past him.Step back away from the sterile field to sneeze or cough.More items...?