The Washington Maintenance Assistance — Technician Checklist is a comprehensive tool used by maintenance technicians to ensure efficient and effective execution of maintenance tasks. This checklist plays a crucial role in documenting and tracking maintenance activities, and it serves as a reference guide for technicians to ensure they cover all the necessary steps during their maintenance tasks. Key Responsibilities Included in the Washington Maintenance Assistance — Technician Checklist— - Equipment Inspection: Technicians are required to thoroughly inspect equipment such as HVAC systems, electrical panels, plumbing fixtures, and other machinery to identify any signs of wear and tear, malfunctions, or potential issues. — Regular Maintenance Tasks: The checklist includes a list of routine maintenance tasks that technicians need to perform, such as changing filters, lubricating moving parts, adjusting tension belts, checking fluid levels, and replacing worn-out components as necessary. — Safety Checks: Ensuring the safety of both technicians and occupants is paramount. Therefore, the checklist includes safety protocols to be followed, like wearing personal protective equipment (PPE), conducting electrical safety tests, and inspecting fire extinguishers and emergency exit signs. Record keepingng: Technicians must document all maintenance activities, including the date, time, actions performed, and any identified issues. This record keeping helps supervisors track completed tasks and plan future maintenance schedules. Types of Washington Maintenance Assistance — Technician Checklists: 1. Residential Maintenance Assistance — Technician Checklist: Specifically designed for maintenance technicians working in residential properties, this checklist covers tasks related to HVAC systems, plumbing, electrical systems, and general repairs required in houses or apartments. 2. Commercial Maintenance Assistance — Technician Checklist: Tailored for maintenance technicians in commercial buildings, this checklist encompasses tasks related to large-scale HVAC systems, elevators, generators, fire safety systems, and other complex equipment found in office buildings, shopping malls, or hotels. 3. Industrial Maintenance Assistance — Technician Checklist: Geared towards technicians working in industrial settings, this checklist focuses on maintaining heavy machinery, production lines, conveyor systems, and plant infrastructure like boilers and cooling towers. It also emphasizes compliance with occupational health and safety regulations specific to the industry. Irrespective of the specific type, the Washington Maintenance Assistance — Technician Checklist ensures technicians adhere to high-quality standards, promotes regular maintenance practices, and contributes to the longevity and optimal performance of the equipment and systems they oversee.

Washington Maintenance Assistance - Technician Checklist

Description

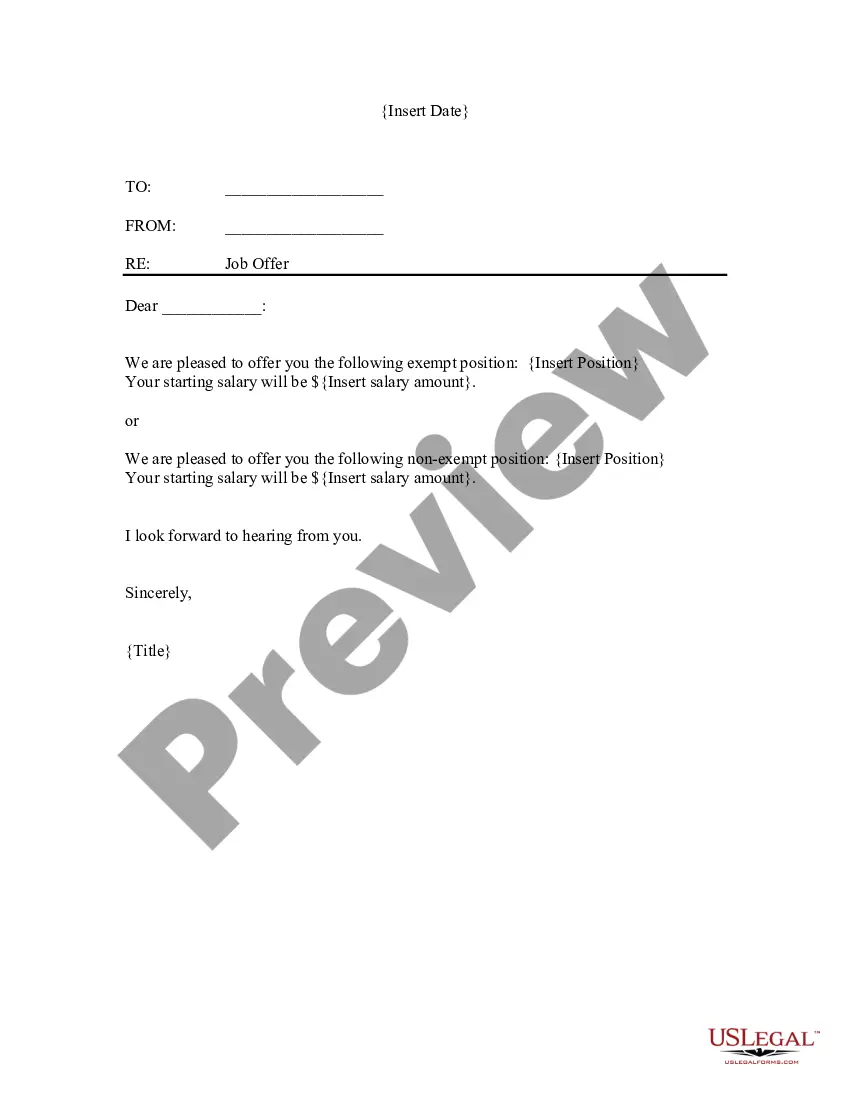

How to fill out Washington Maintenance Assistance - Technician Checklist?

Choosing the best authorized file format can be a have difficulties. Needless to say, there are plenty of web templates available on the net, but how can you get the authorized form you need? Utilize the US Legal Forms website. The service offers a large number of web templates, for example the Washington Maintenance Assistance - Technician Checklist, that can be used for company and personal requirements. Every one of the varieties are examined by pros and fulfill federal and state needs.

Should you be already authorized, log in to the account and click the Acquire switch to find the Washington Maintenance Assistance - Technician Checklist. Use your account to appear with the authorized varieties you possess bought formerly. Proceed to the My Forms tab of the account and acquire yet another backup in the file you need.

Should you be a whole new consumer of US Legal Forms, allow me to share easy directions that you can comply with:

- First, make sure you have selected the right form for the city/area. You are able to look over the shape making use of the Review switch and look at the shape outline to make sure it is the right one for you.

- In case the form does not fulfill your requirements, utilize the Seach industry to obtain the proper form.

- When you are certain the shape is suitable, go through the Buy now switch to find the form.

- Select the costs program you would like and type in the essential details. Make your account and purchase the transaction with your PayPal account or Visa or Mastercard.

- Pick the submit structure and obtain the authorized file format to the device.

- Total, edit and printing and indication the attained Washington Maintenance Assistance - Technician Checklist.

US Legal Forms will be the most significant collection of authorized varieties in which you will find numerous file web templates. Utilize the service to obtain professionally-made paperwork that comply with status needs.