Wisconsin Manufacturer Analysis Checklist

Description

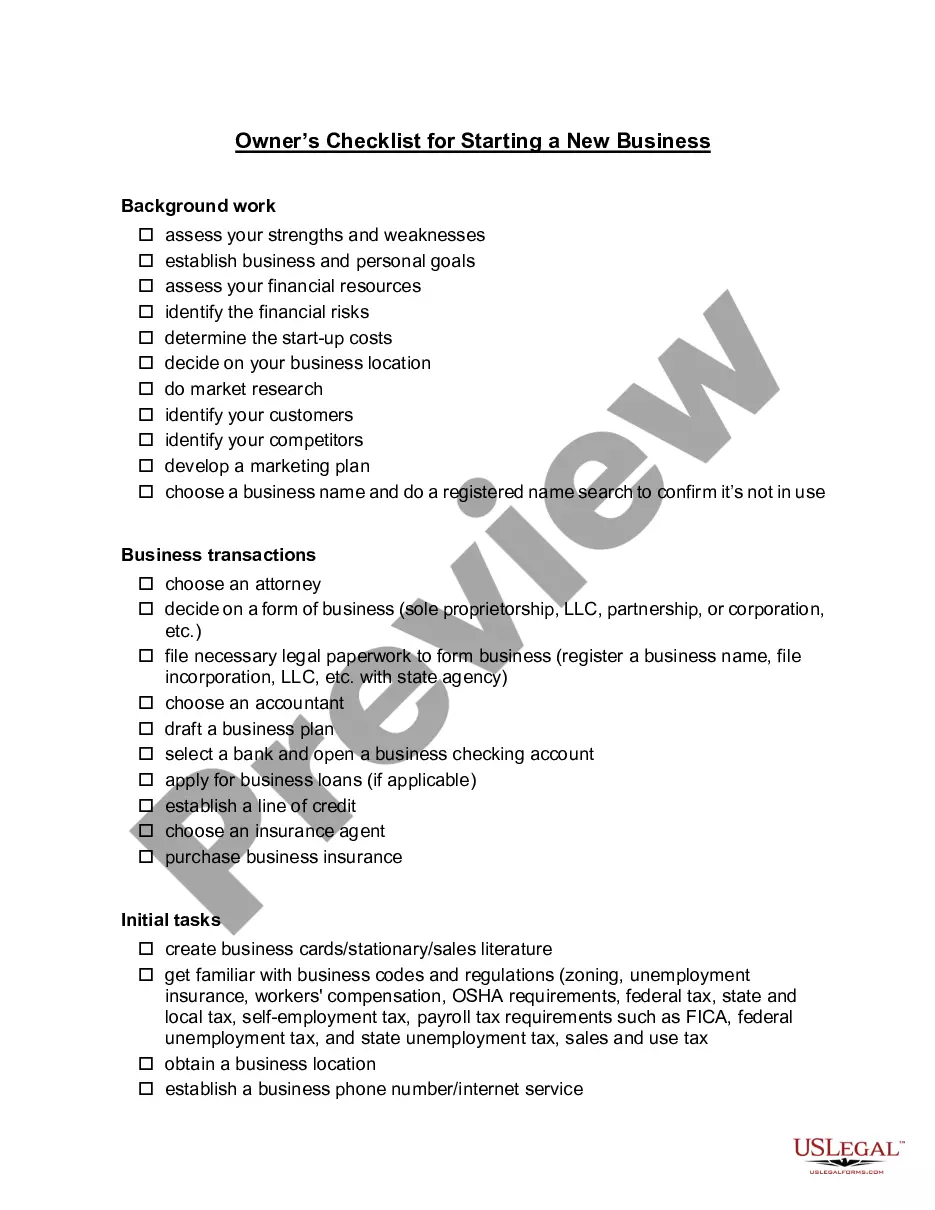

How to fill out Manufacturer Analysis Checklist?

If you aim to finalize, obtain, or create sanctioned document templates, utilize US Legal Forms, the most extensive collection of legal forms available online.

Employ the website’s straightforward and convenient search to locate the documents you need.

Numerous templates for commercial and personal purposes are organized by categories and jurisdictions, or keywords.

Every legal document template you obtain belongs to you permanently. You will have access to every form you saved in your account.

Click on the My documents section and choose a form to print or download again. Complete and download, and print the Wisconsin Manufacturer Analysis Checklist with US Legal Forms. There are thousands of professional and state-specific forms available for your business or individual needs.

- Use US Legal Forms to find the Wisconsin Manufacturer Analysis Checklist within a few clicks.

- If you are currently a US Legal Forms user, sign in to your account and click the Download button to access the Wisconsin Manufacturer Analysis Checklist.

- You can also retrieve forms you previously saved in the My documents section of your account.

- If you are using US Legal Forms for the first time, refer to the instructions below.

- Step 1. Ensure you have selected the form for the correct city/state.

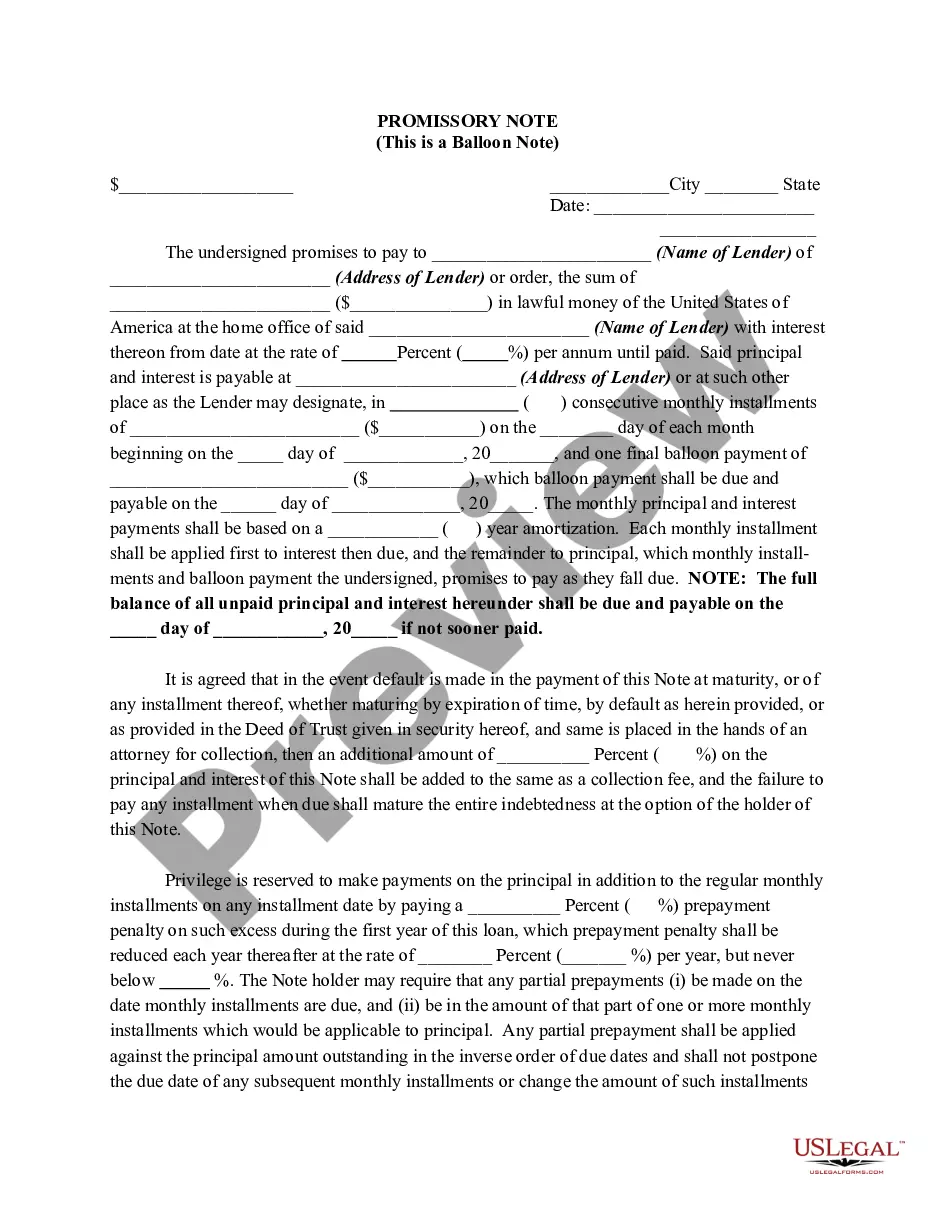

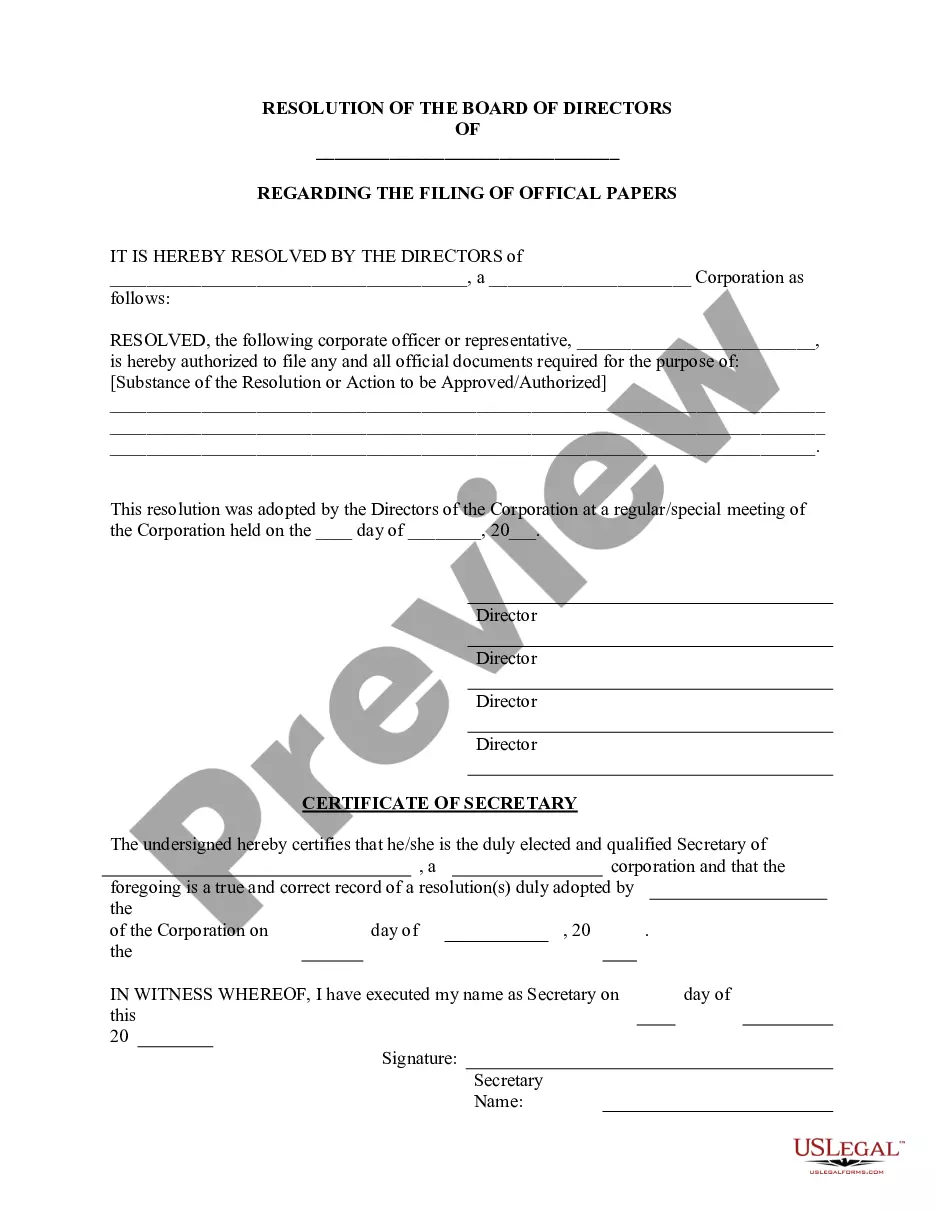

- Step 2. Utilize the Review option to check the form’s details. Remember to read the description.

- Step 3. If you are not satisfied with the form, use the Search field at the top of the screen to find alternative versions of the legal form template.

- Step 4. Once you have located the form you need, click the Acquire now button. Choose the payment plan you prefer and enter your information to register for the account.

- Step 5. Complete the transaction. You can use your credit card or PayPal account to finalize the purchase.

- Step 6. Select the format of your legal form and download it to your device.

- Step 7. Complete, modify, and print or sign the Wisconsin Manufacturer Analysis Checklist.

Form popularity

FAQ

Yes, Wisconsin has a state withholding form that employers use to report income tax withheld from employee wages. This form is vital for maintaining accurate payroll records. Employers must understand the filing requirements to avoid penalties. The Wisconsin Manufacturer Analysis Checklist provides resources to help you manage payroll effectively.

Wisconsin's personal property tax is levied on tangible goods owned by individuals and businesses. This tax helps fund local services and is assessed annually. Manufacturers need to understand their obligations related to this tax. By following the Wisconsin Manufacturer Analysis Checklist, you can ensure compliance and optimize your tax strategy.

To obtain a Wisconsin sales tax ID number, you can apply online through the Wisconsin Department of Revenue’s website. It’s an essential step for businesses engaged in sales within the state. Having this ID allows you to collect and remit sales tax responsibly. Using the Wisconsin Manufacturer Analysis Checklist can help you navigate this application process smoothly.

The Wisconsin real estate transfer return is a document that must be filed whenever real property is sold. This form ensures that the state has accurate information about property transfers. Proper handling of this return is crucial for compliance with tax laws. Incorporating this into your Wisconsin Manufacturer Analysis Checklist can simplify real estate transactions.

Yes, Wisconsin is a significant manufacturing state with a rich history in various sectors. The state is known for producing machinery, food products, and other goods. Manufacturing plays a vital role in Wisconsin's economy and job market. Understanding this landscape is essential when using the Wisconsin Manufacturer Analysis Checklist.

The Wisconsin dealer reassignment form is a document used to transfer the ownership of a vehicle from one dealer to another. This is essential for maintaining accurate records during vehicle sales. By completing this form, dealers ensure legal compliance with state regulations. Our Wisconsin Manufacturer Analysis Checklist provides guidance on managing such forms.

Yes, Wisconsin has a state income tax form that residents must fill out each year. It’s important to keep track of your earnings and deductions to ensure accurate filing. This information is critical for complying with state regulations. Using our Wisconsin Manufacturer Analysis Checklist can help streamline the tax preparation process.