West Virginia Manufacturer Analysis Checklist

Description

How to fill out Manufacturer Analysis Checklist?

US Legal Forms - one of the foremost collections of legal documents in the United States - provides a variety of legal document templates that you can obtain or create.

Utilizing the website, you will access countless forms for business and personal purposes, organized by categories, states, or keywords. You can find the latest types of forms such as the West Virginia Manufacturer Analysis Checklist in moments.

If you already have a subscription, Log In and obtain the West Virginia Manufacturer Analysis Checklist from your US Legal Forms catalog. The Download option will appear on every document you view. You have access to all previously saved forms in the My documents section of your profile.

Complete the transaction. Use your credit card or PayPal account to finalize the purchase.

Choose the format and download the form to your device. Edit the document. Fill out, modify, print, and sign the downloaded West Virginia Manufacturer Analysis Checklist. Each form you added to your account has no expiration date and is yours indefinitely. Therefore, if you wish to download or print another copy, simply visit the My documents section and click on the form you need.

- Make certain you have selected the correct form for your area/region.

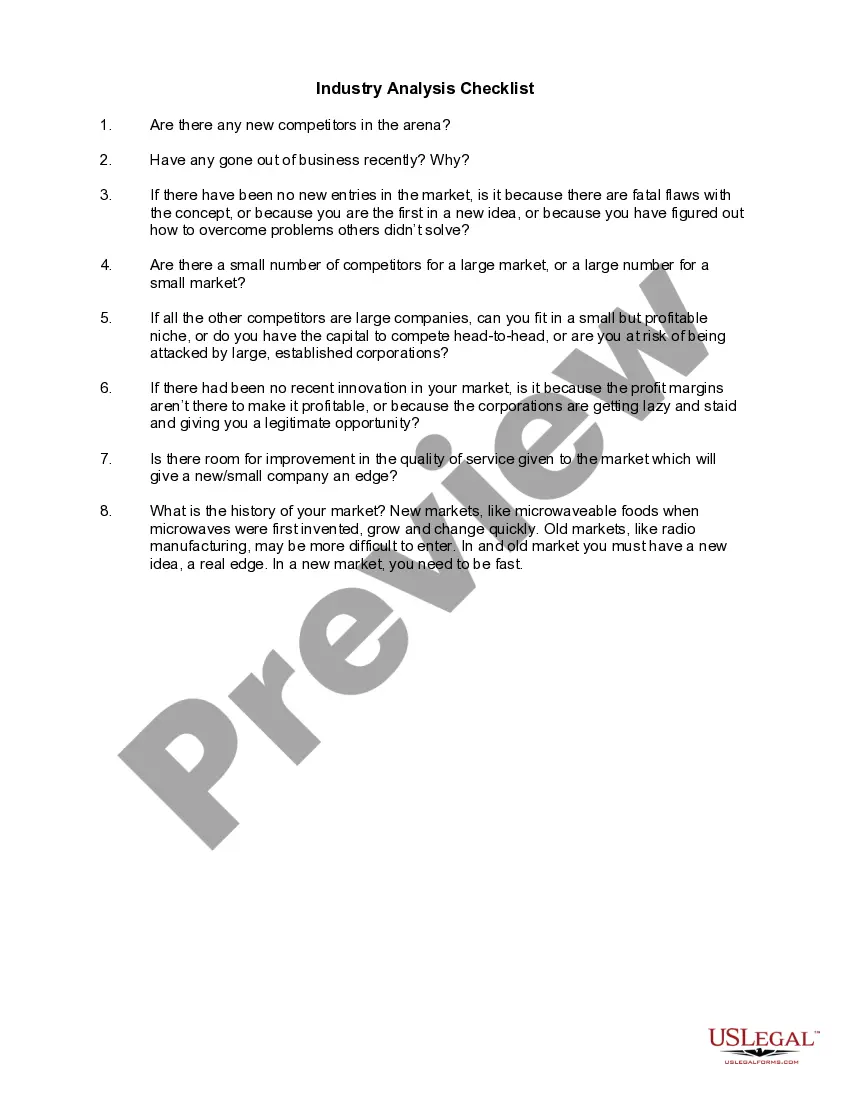

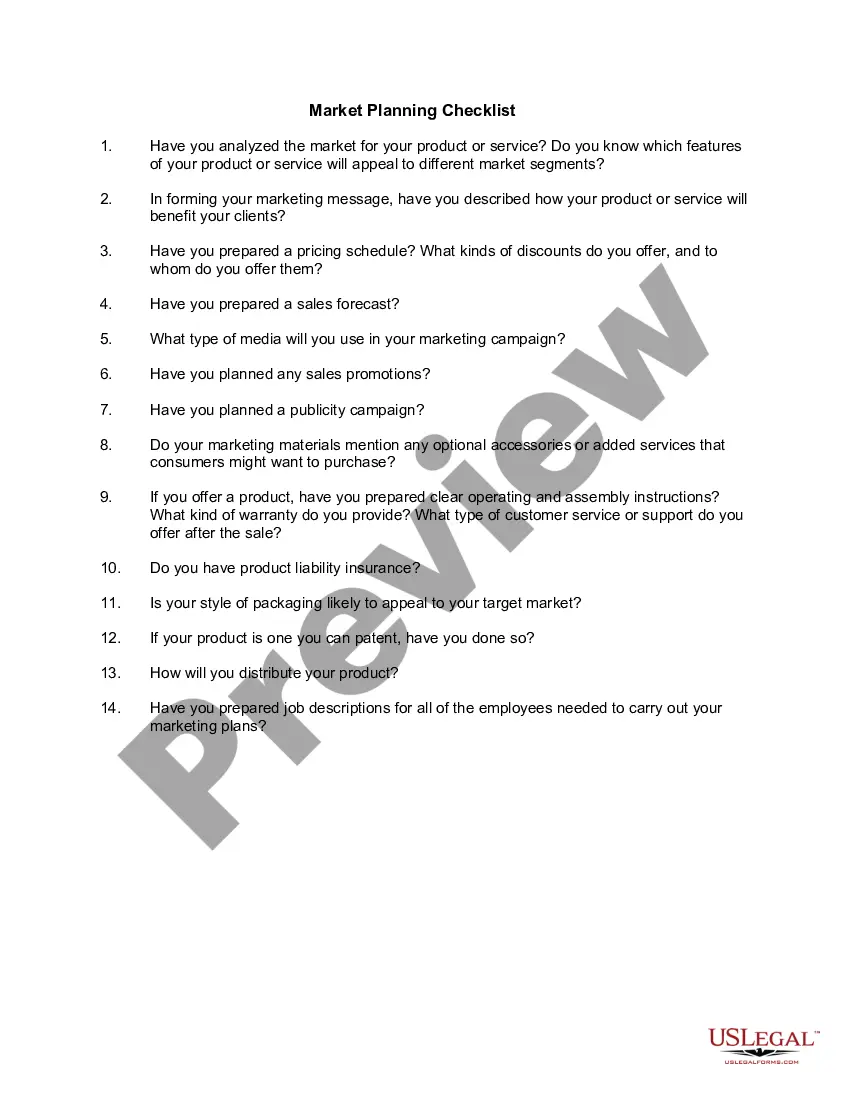

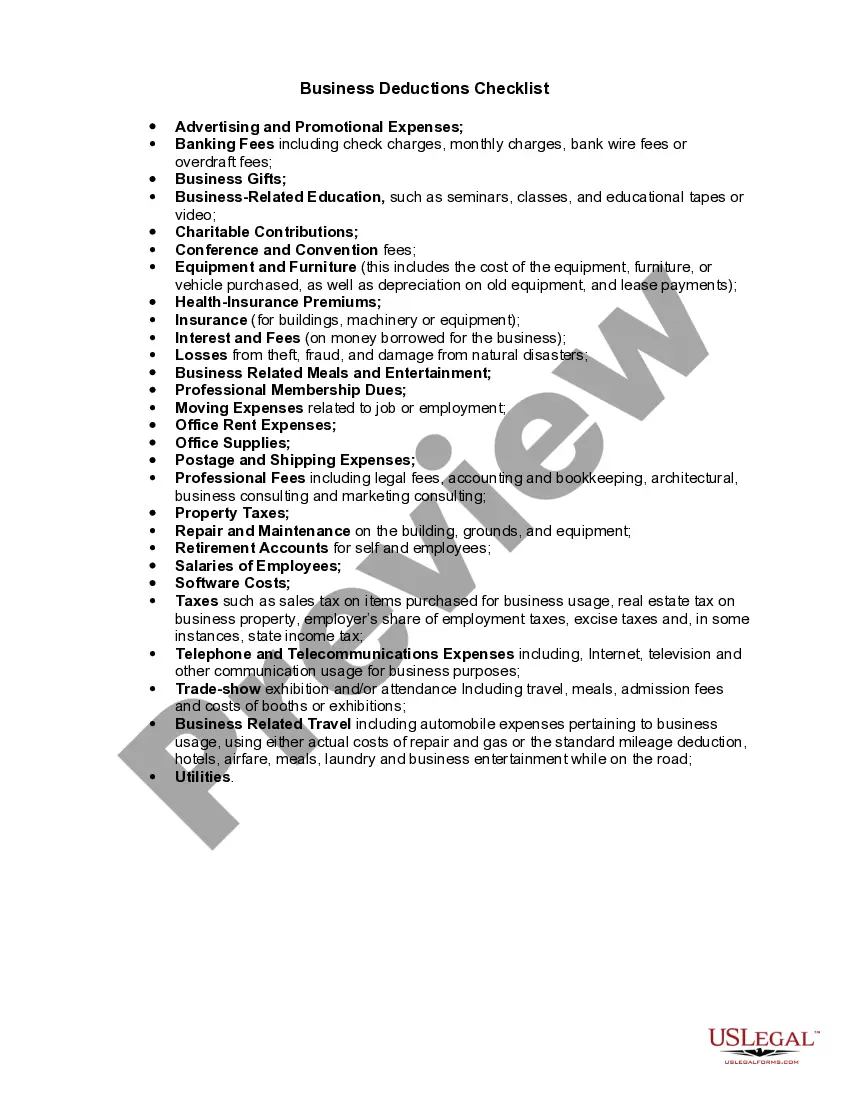

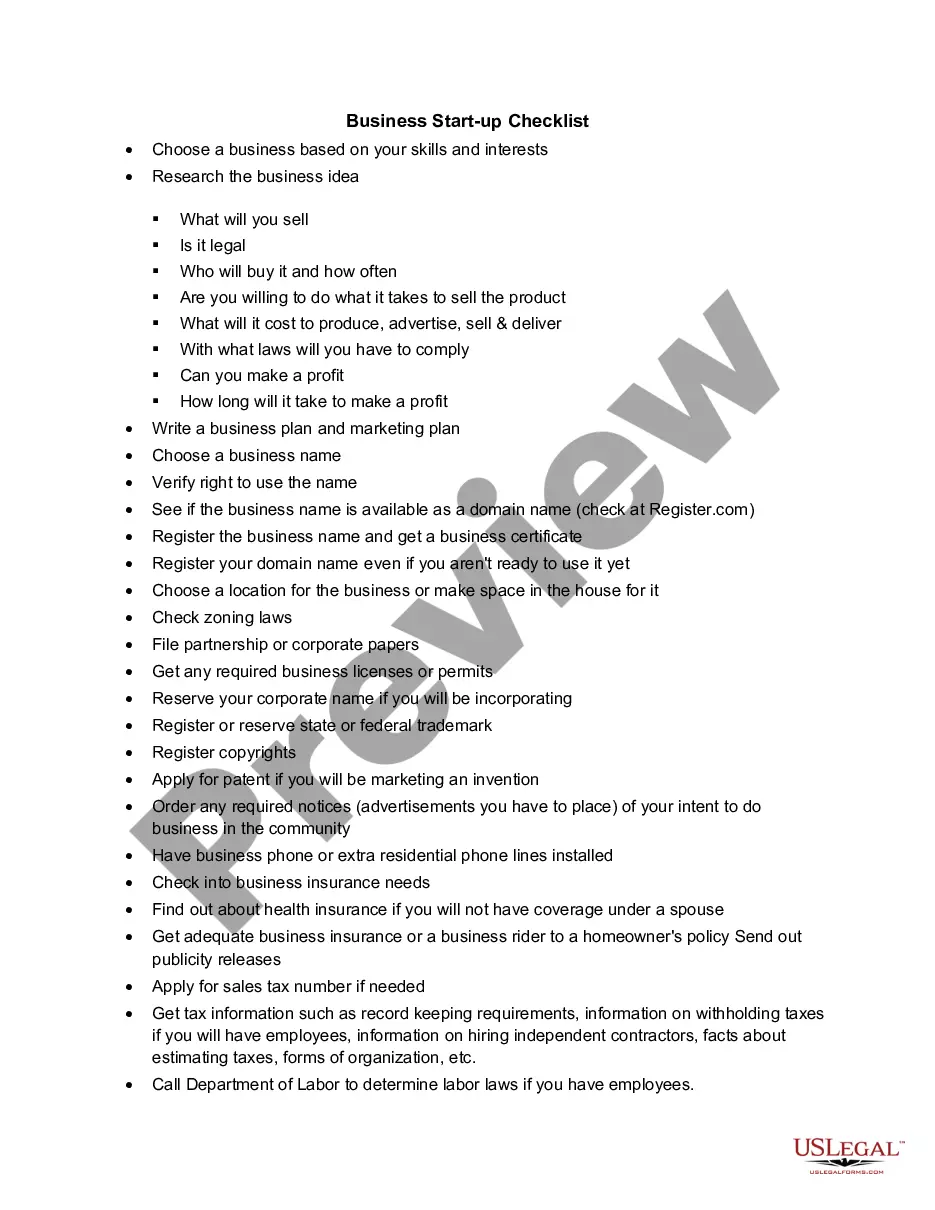

- Click the Preview option to review the form’s content.

- Check the form description to ensure it is the right one.

- If the form does not meet your requirements, use the Search field at the top of the screen to find one that does.

- If you are satisfied with the form, confirm your choice by clicking the Purchase now button.

- Then, select your preferred pricing plan and provide your details to register for an account.

Form popularity

FAQ

Yes, West Virginia follows market-based sourcing rules for determining where sales occur. This means that sales are attributed to the location where the customer receives the benefit of the product or service. When preparing your West Virginia Manufacturer Analysis Checklist, it's vital to keep this sourcing method in mind, as it can greatly influence your tax obligations.

Yes, West Virginia imposes a gross receipts tax on certain business transactions. This tax is calculated based on a company's total revenue rather than profits, which can impact your manufacturing operations. Understanding this tax, as highlighted in your West Virginia Manufacturer Analysis Checklist, will provide essential insights into your overall business operations.

The schedule UB CR in West Virginia details the annual business personal property tax report. This schedule is essential for manufacturers to accurately report their assets for tax purposes. By including this information in your West Virginia Manufacturer Analysis Checklist, you can ensure compliance and avoid potential penalties.

To obtain an Employer Identification Number (EIN) in West Virginia, you can apply online through the IRS website. This number is essential for various business activities, including hiring employees and filing taxes. Incorporating this step in your West Virginia Manufacturer Analysis Checklist ensures you cover all necessary requirements for establishing your business.

West Virginia ranks 41st in size among the states in the United States, covering approximately 24,230 square miles. While it may not be the largest state, its strategic location and rich resources offer significant opportunities for manufacturers. When using the West Virginia Manufacturer Analysis Checklist, consider how the state's size and geography may influence your operations.

Yes, West Virginia utilizes a single sales factor for its corporate income tax. This approach can be advantageous for manufacturers, as it encourages investment and growth within the state. If you are working through the West Virginia Manufacturer Analysis Checklist, being aware of this tax structure can inform your business decisions and strategies.

A single sales factor is a method used to determine a company's tax liability based solely on the percentage of its sales within a specific state. This approach simplifies the tax calculation process, making it easier for manufacturers to assess their tax obligations. In the context of the West Virginia Manufacturer Analysis Checklist, understanding this factor can help you navigate tax laws more effectively.