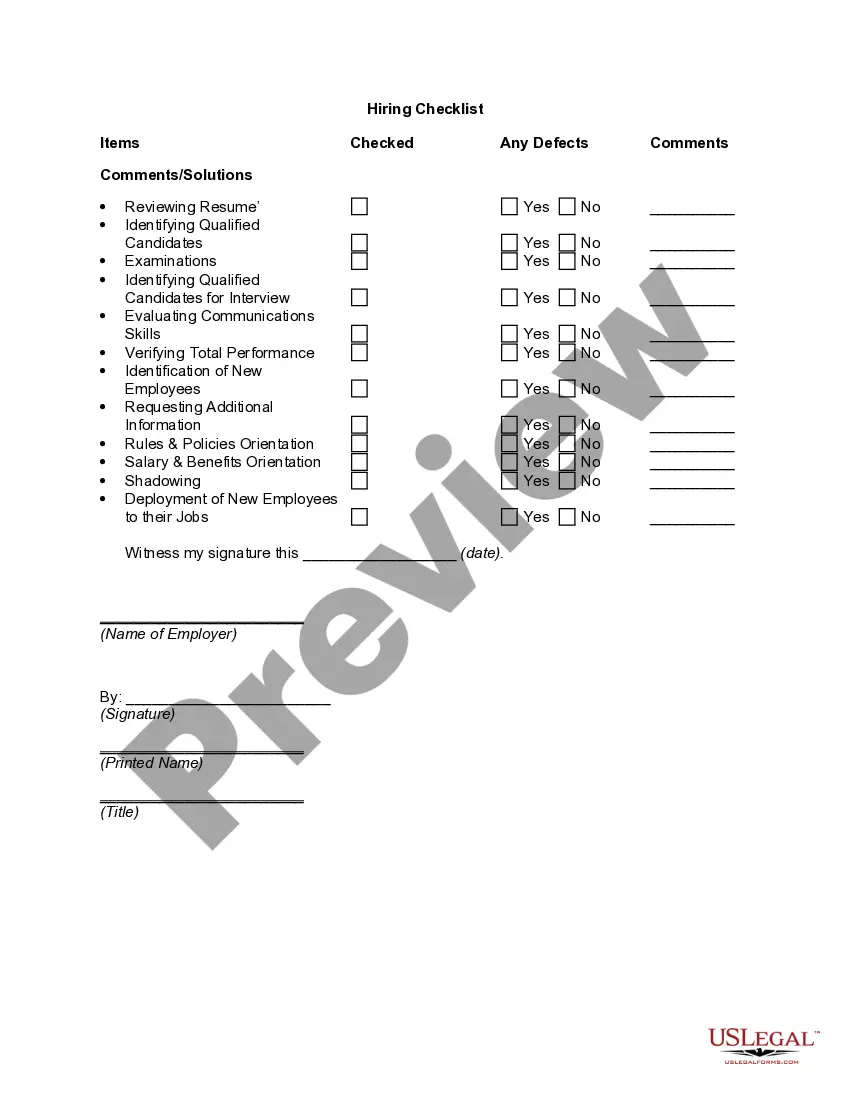

West Virginia Maintenance Assistance - Technician Checklist

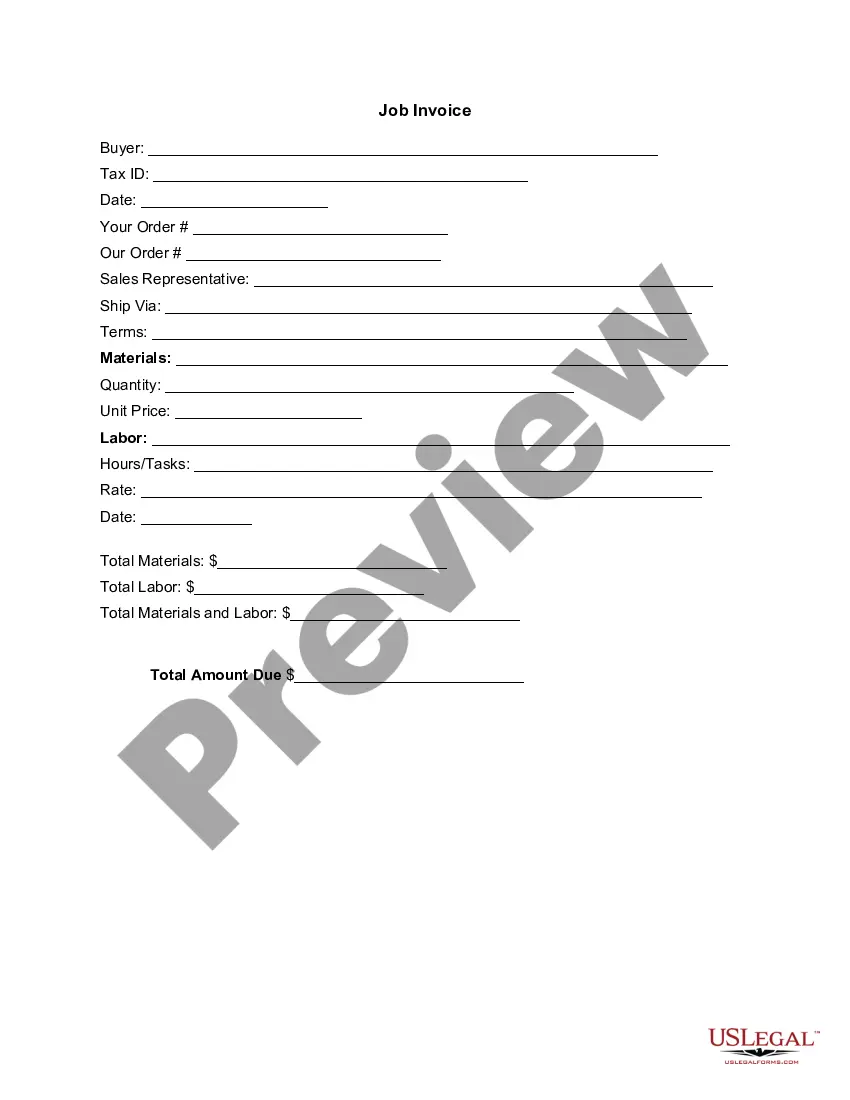

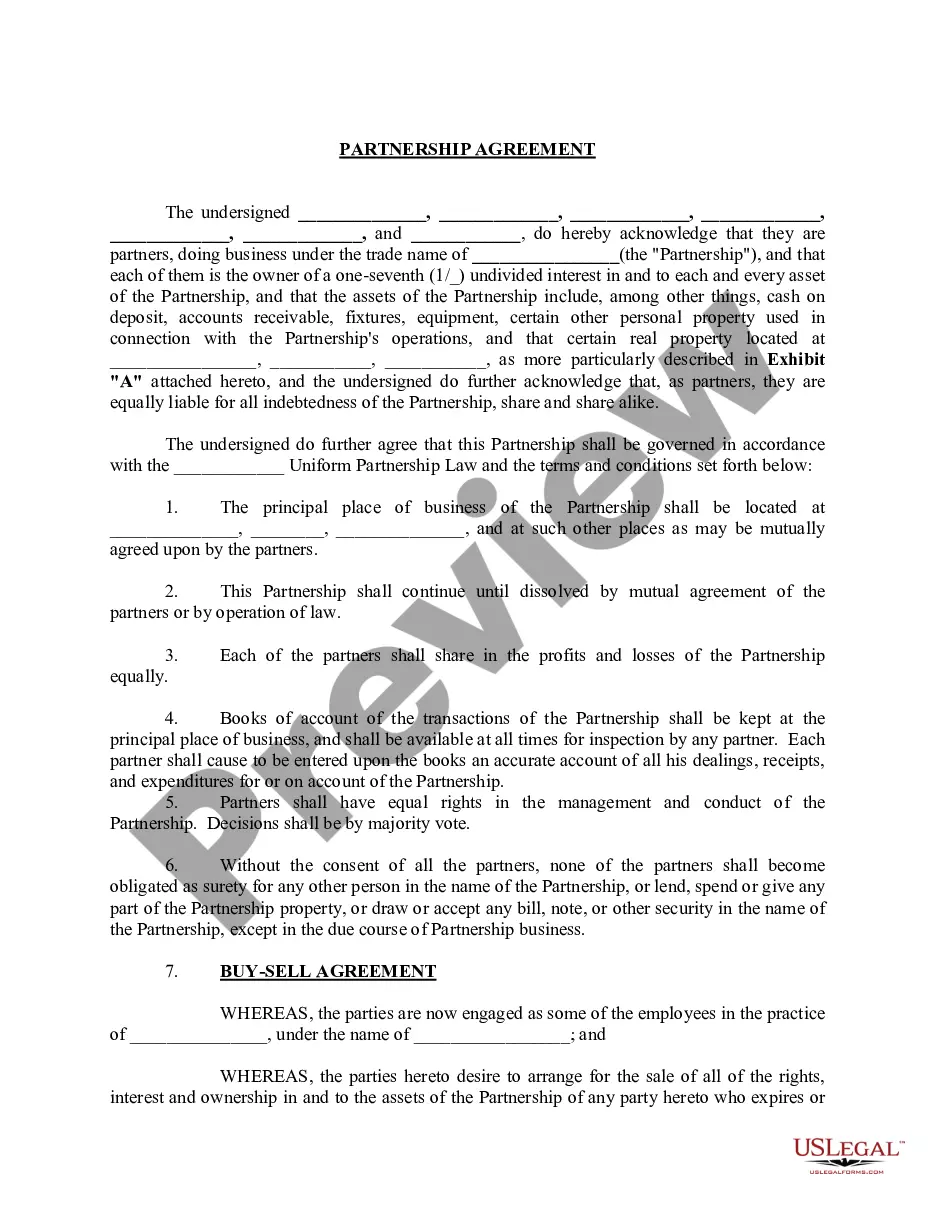

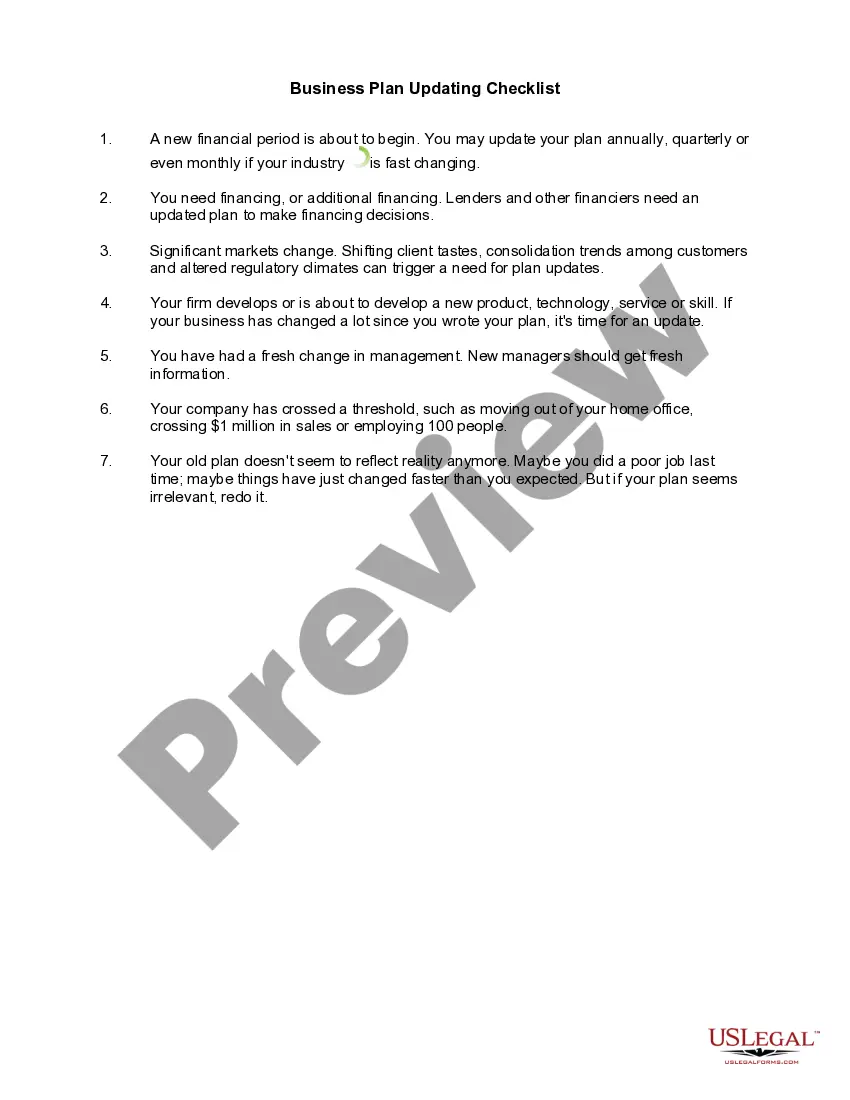

Description

How to fill out Maintenance Assistance - Technician Checklist?

Selecting the correct legal document template could pose a challenge. Clearly, there are numerous templates accessible online, but how do you find the legal form you require.

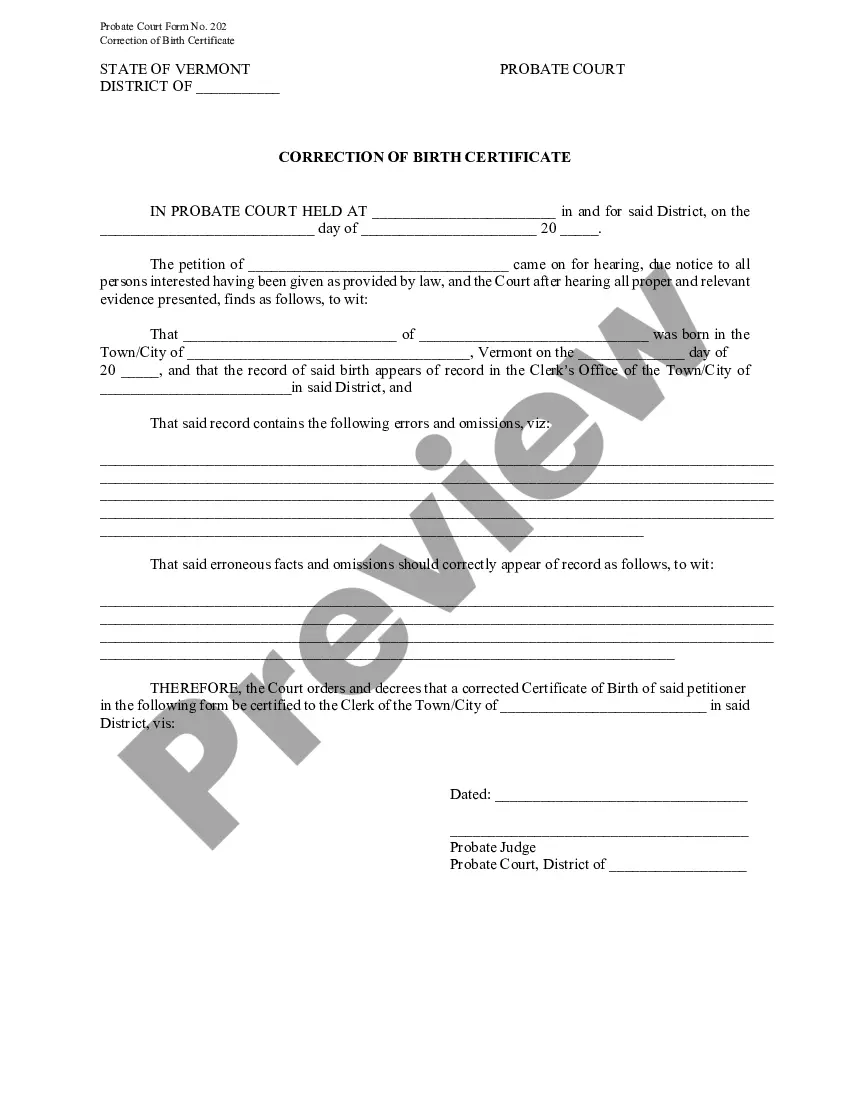

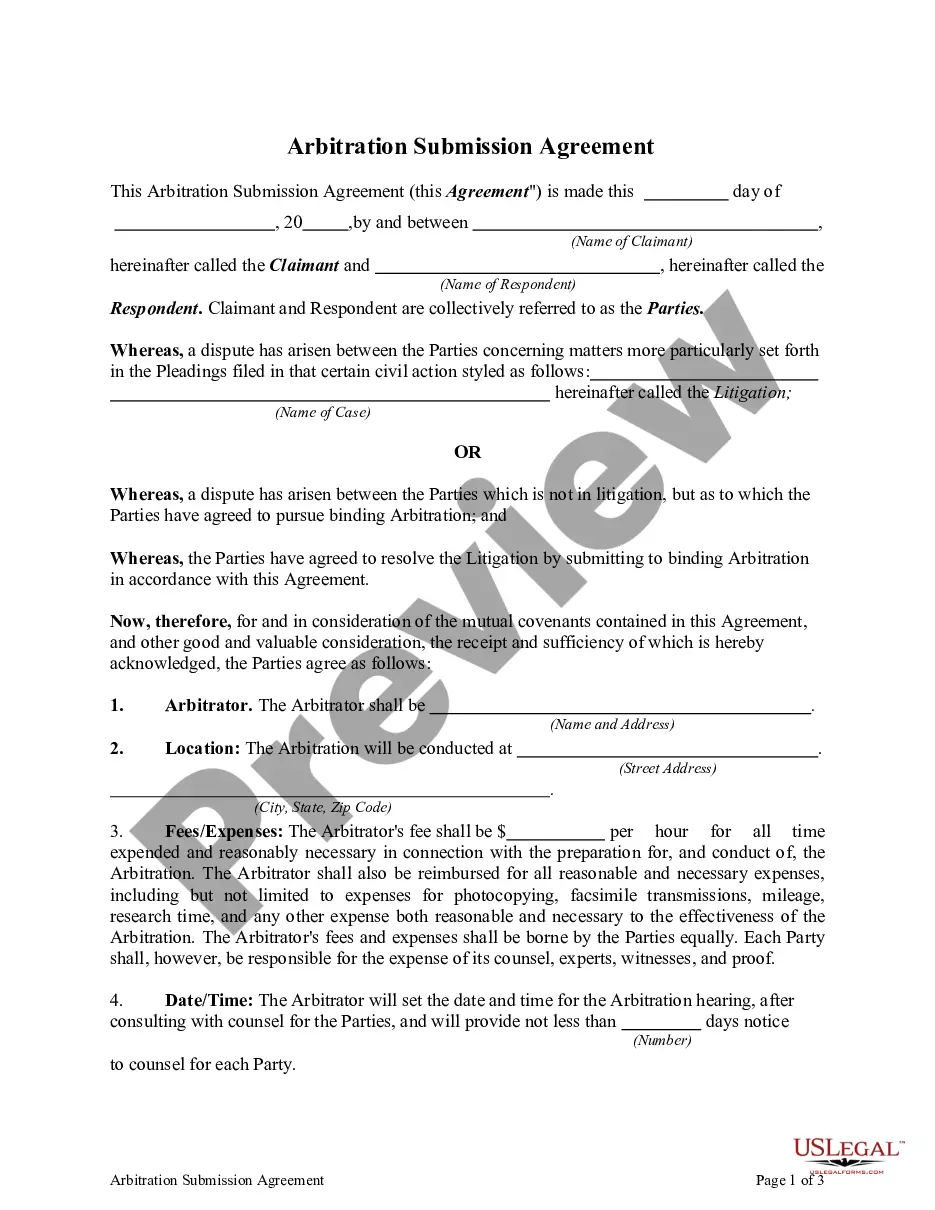

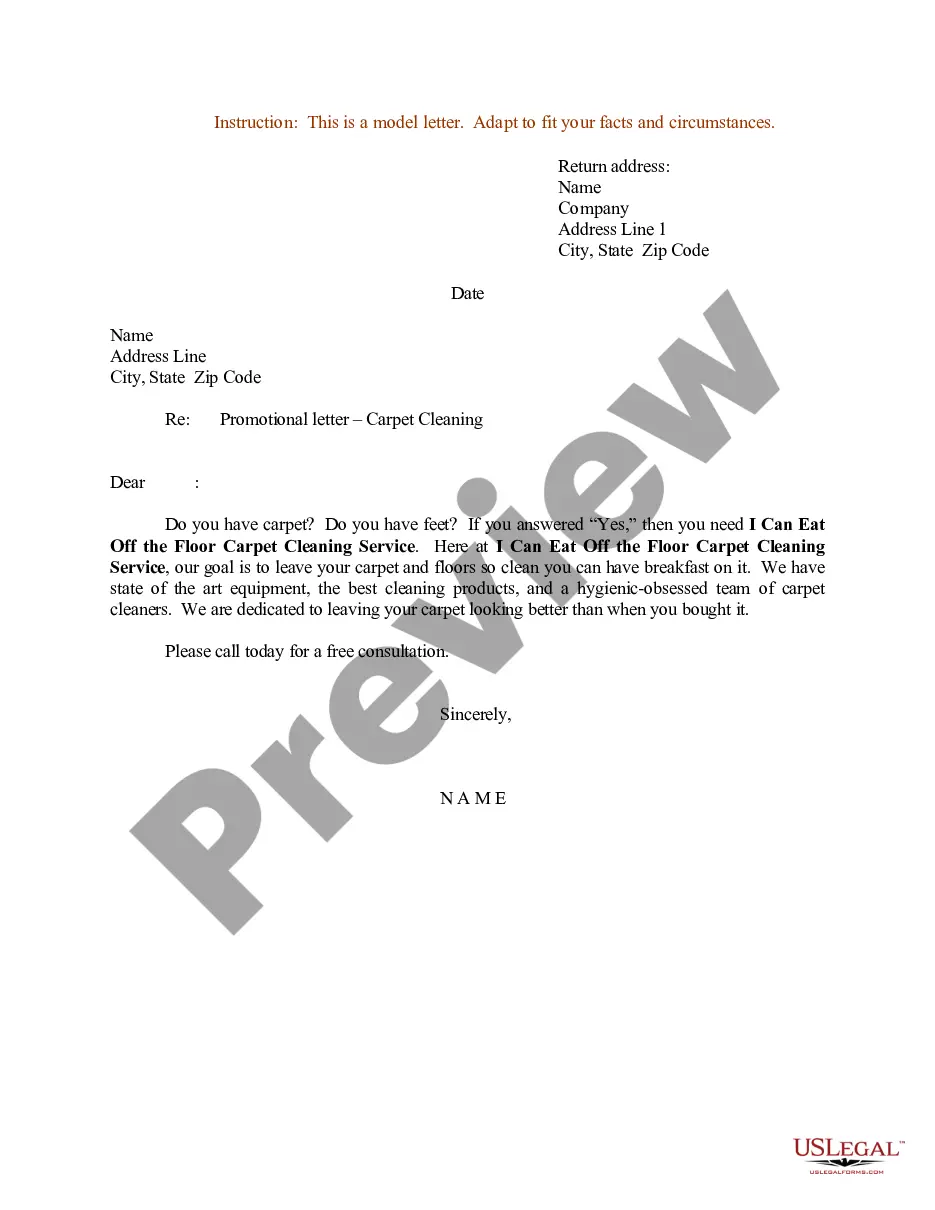

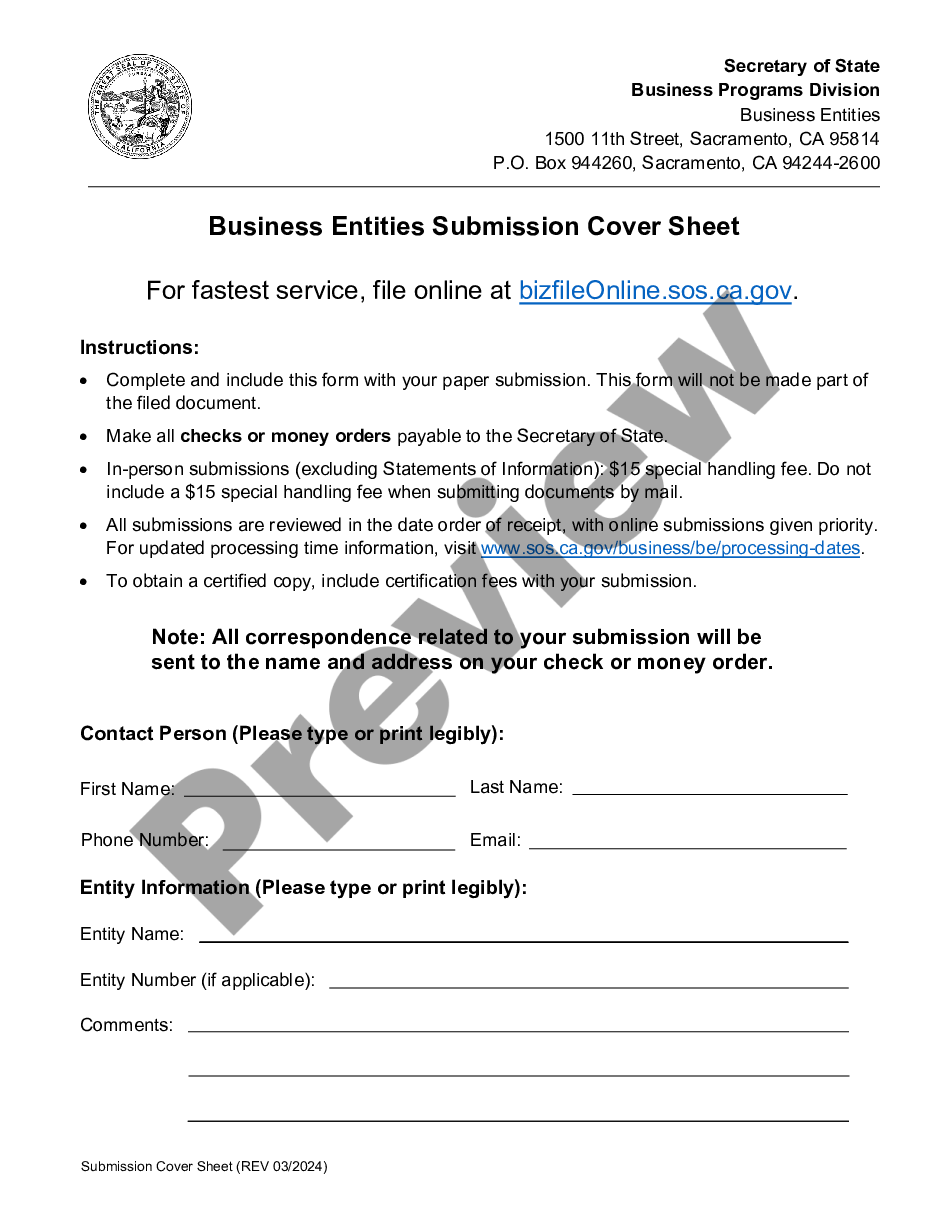

Utilize the US Legal Forms website. The service offers a vast array of templates, such as the West Virginia Maintenance Assistance - Technician Checklist, suitable for both business and personal needs. All forms are reviewed by experts and comply with state and federal regulations.

If you are already registered, Log In to your account and click the Download button to obtain the West Virginia Maintenance Assistance - Technician Checklist. Use your account to browse the legal forms you have purchased previously. Visit the My documents tab of the account to get another copy of the document you need.

Complete, modify, print, and sign the retrieved West Virginia Maintenance Assistance - Technician Checklist. US Legal Forms is the largest repository of legal forms from which you can find various document templates. Utilize the service to acquire professionally crafted documents that adhere to state regulations.

- If you are a new user of US Legal Forms, here are simple instructions for you to follow.

- First, make sure you have chosen the correct form for your city/county. You can view the form using the Review button and read the form description to confirm it is the one you need.

- If the form does not meet your needs, utilize the Search field to find the appropriate form.

- When you are confident that the form is suitable, select the Acquire now button to obtain the form.

- Choose the pricing plan you wish and enter the required information. Create your account and purchase the order using your PayPal account or credit card.

- Select the file format and download the legal document template for your records.