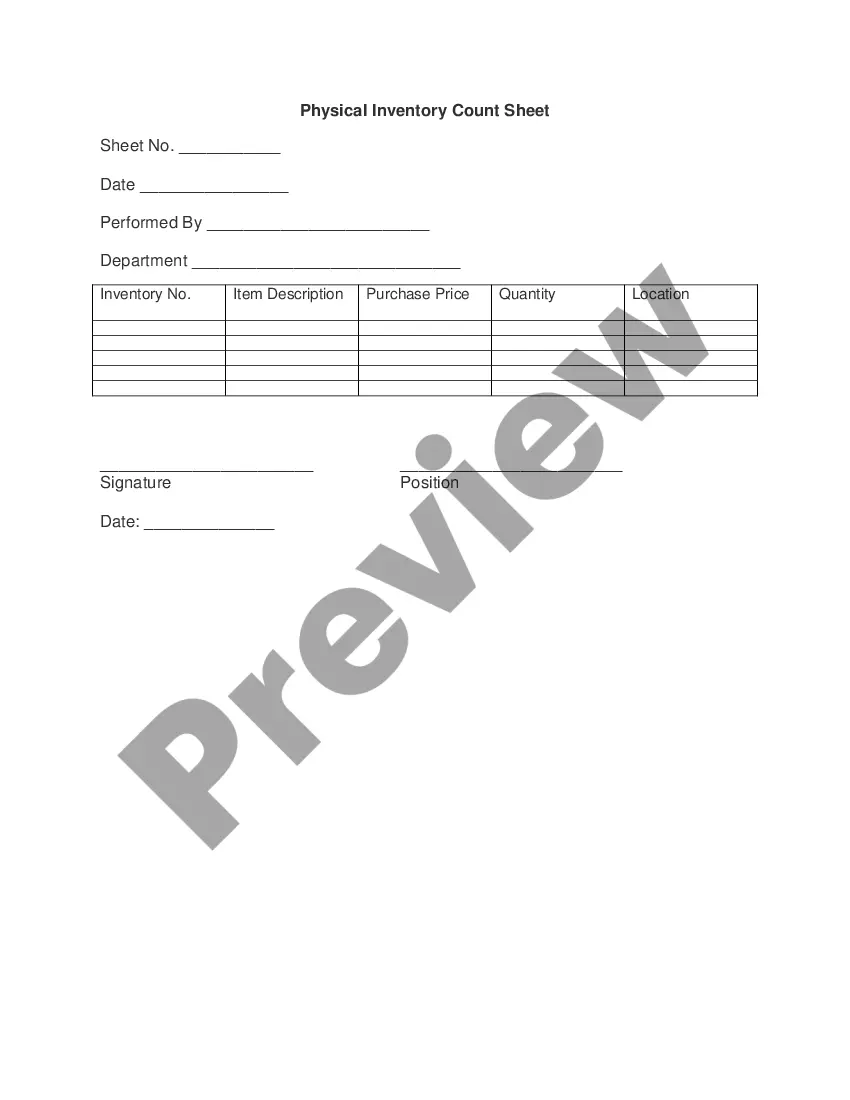

Wyoming Physical Inventory Count Sheet

Description

How to fill out Physical Inventory Count Sheet?

Have you ever found yourself in a situation where documentation is required for perhaps professional or particular purposes most of the time.

There is a plethora of legal document templates accessible online, but locating ones you can trust can be challenging.

US Legal Forms offers a vast collection of form templates, including the Wyoming Physical Inventory Count Sheet, designed to comply with state and federal regulations.

Once you identify the correct form, click Purchase now.

Choose the pricing plan you prefer, complete the necessary information for payment, and finalize the purchase using your PayPal or credit card.

- If you are already familiar with the US Legal Forms website and possess an account, simply sign in.

- Then, you can download the Wyoming Physical Inventory Count Sheet template.

- If you do not have an account and wish to start using US Legal Forms, follow these instructions.

- Select the form you require and ensure it is appropriate for your location/county.

- Utilize the Preview button to review the document.

- Check the description to confirm you have selected the correct form.

- If the form isn’t what you’re looking for, use the Search section to find the form that suits your needs and requirements.

Form popularity

FAQ

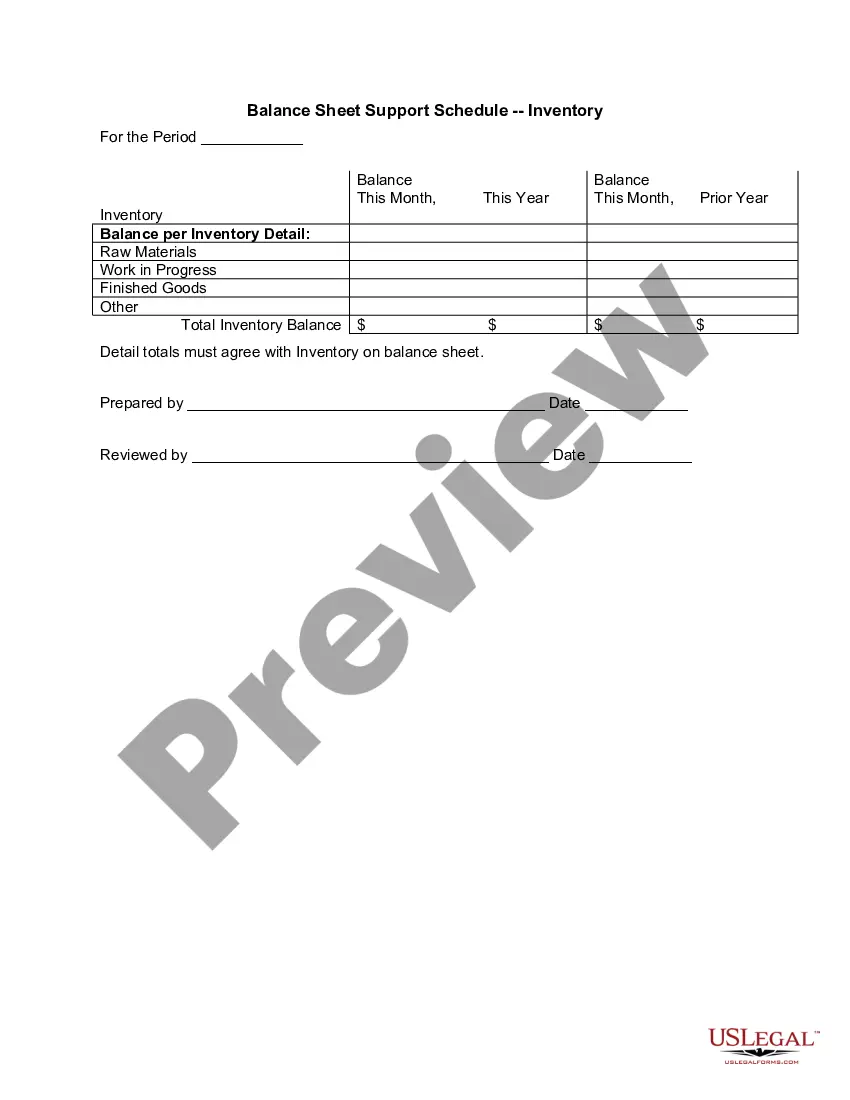

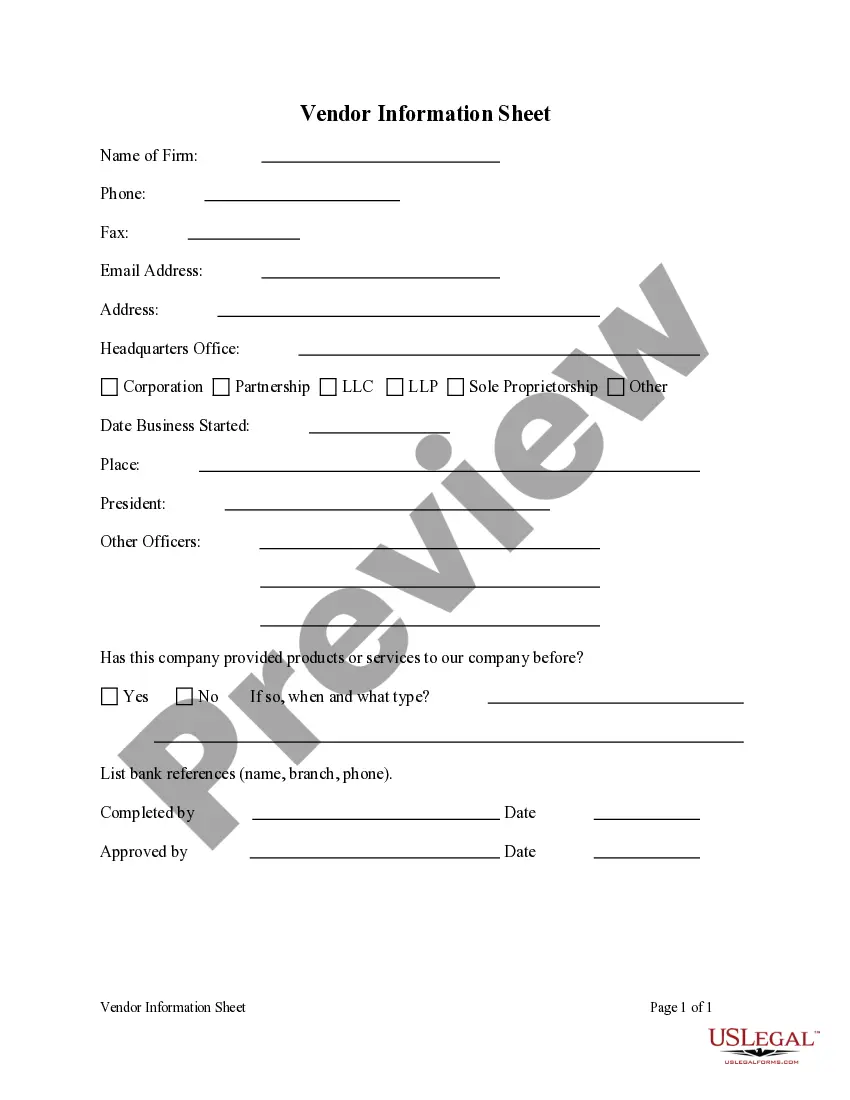

A physical count of inventory can identify discrepancies, such as missing items, overstocked products, or accounting errors. By conducting regular counts, you can maintain better control over your inventory and improve financial reporting. Implementing a structured Wyoming Physical Inventory Count Sheet helps you systematically track these insights, ultimately enhancing your business operations.

The physical count of inventory refers to the actual count of all stock items available at a given time. This count is crucial for reconciling financial records and ensuring that your inventory management is accurate. A well-organized Wyoming Physical Inventory Count Sheet can help track discrepancies between recorded and actual inventory, leading to improved control.

A physical inventory is usually taken annually, semi-annually, or at the end of a fiscal year to assess stock levels accurately. However, many companies opt for more frequent counts, such as quarterly or monthly, to maintain financial accuracy. Utilize your Wyoming Physical Inventory Count Sheet to record this data systematically, allowing for easier trend tracking and analysis.

The four types of inventory counts include periodic counts, perpetual counts, sample counts, and cycle counts. Each method serves different business needs based on frequency and detail required. For efficient tracking, your Wyoming Physical Inventory Count Sheet can facilitate any of these counting strategies, ensuring you stay organized and informed.

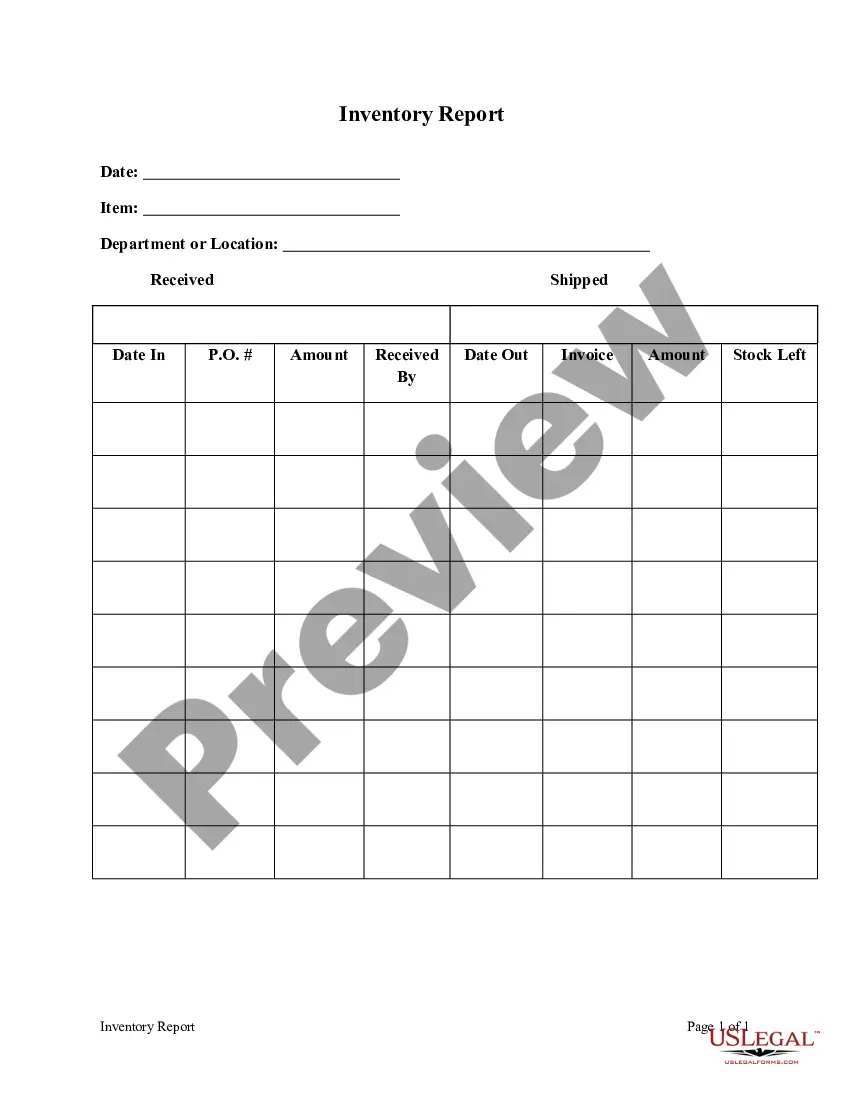

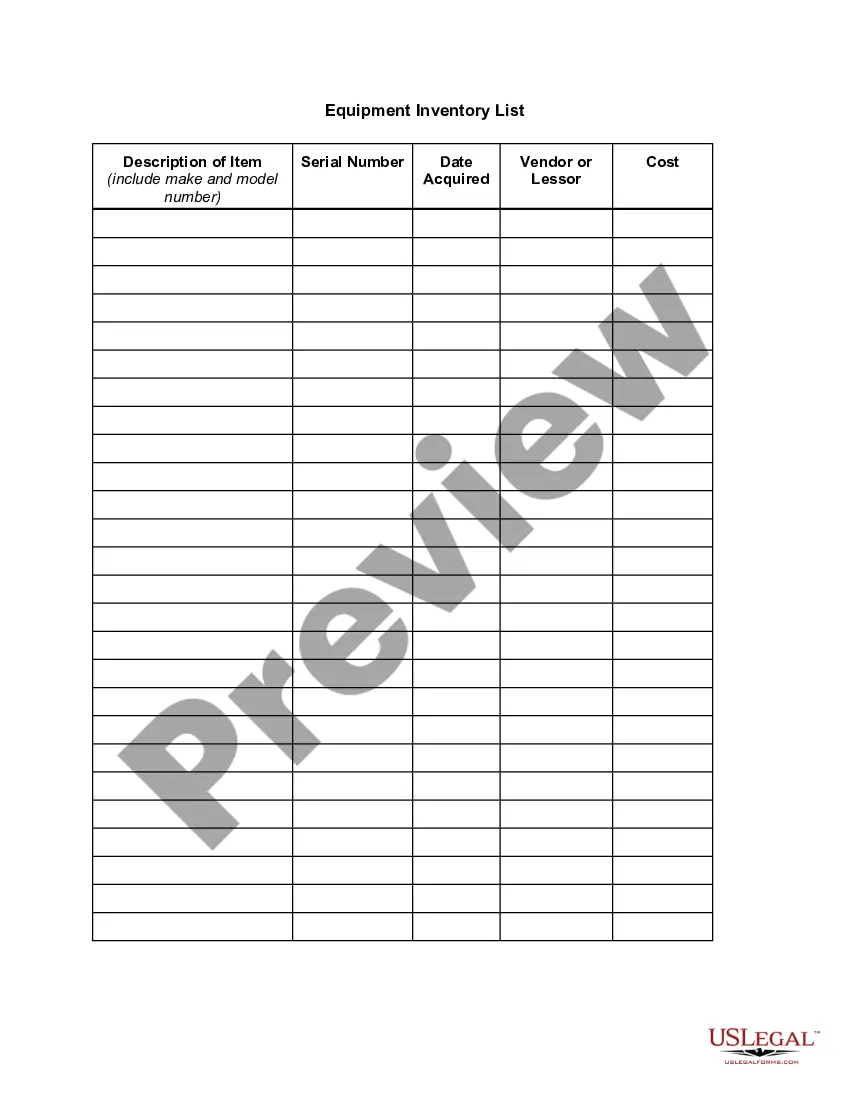

When conducting a physical count of inventory, ensure you account for all items in stock. Focus on labeling and organizing your inventory for easier identification. Your Wyoming Physical Inventory Count Sheet should include details like item descriptions, quantities, and locations to enhance accuracy. This preparation significantly streamlines the counting process.

A report on the physical count of inventories summarizes the results of your inventory count. It typically includes the quantities counted, discrepancies identified, and any adjustments required in your inventory records. Using a Wyoming Physical Inventory Count Sheet can help generate a comprehensive report by consolidating data efficiently. This report is vital for accurate financial reporting and inventory management.

The transaction code (Tcode) for initiating a physical inventory count typically varies by software system. If you're using an inventory management tool, you'll want to refer to its documentation for the specific Tcode. Utilizing a Wyoming Physical Inventory Count Sheet can complement your Tcode process by providing a clear framework for counting and recording inventory accurately. Ensure you familiarize yourself with the tools at your disposal.

To conduct a physical inventory count, start by organizing your inventory items for easy access. Use a Wyoming Physical Inventory Count Sheet to list items and record their quantities as you count. It's essential to work systematically through your storage to ensure accuracy and completeness. Finally, compare the counted quantities with your inventory records to identify differences.

An inventory count sheet is a document that lists all items in your inventory, allowing you to record quantities and details during a physical count. This sheet typically includes item descriptions, quantities, and locations, making it easier for you to keep track of stock. By using a Wyoming Physical Inventory Count Sheet, you can maintain organized records and improve your counting efficiency. Accessing this sheet simplifies the counting process for any business.

An inventory count is a process of verifying the quantity and condition of goods available in your storage. It helps ensure that your records match the actual items on hand. Regular inventory counts aid in identifying discrepancies, preventing stockouts, and enhancing overall inventory management. Utilizing a Wyoming Physical Inventory Count Sheet can streamline this process and ensure accuracy.