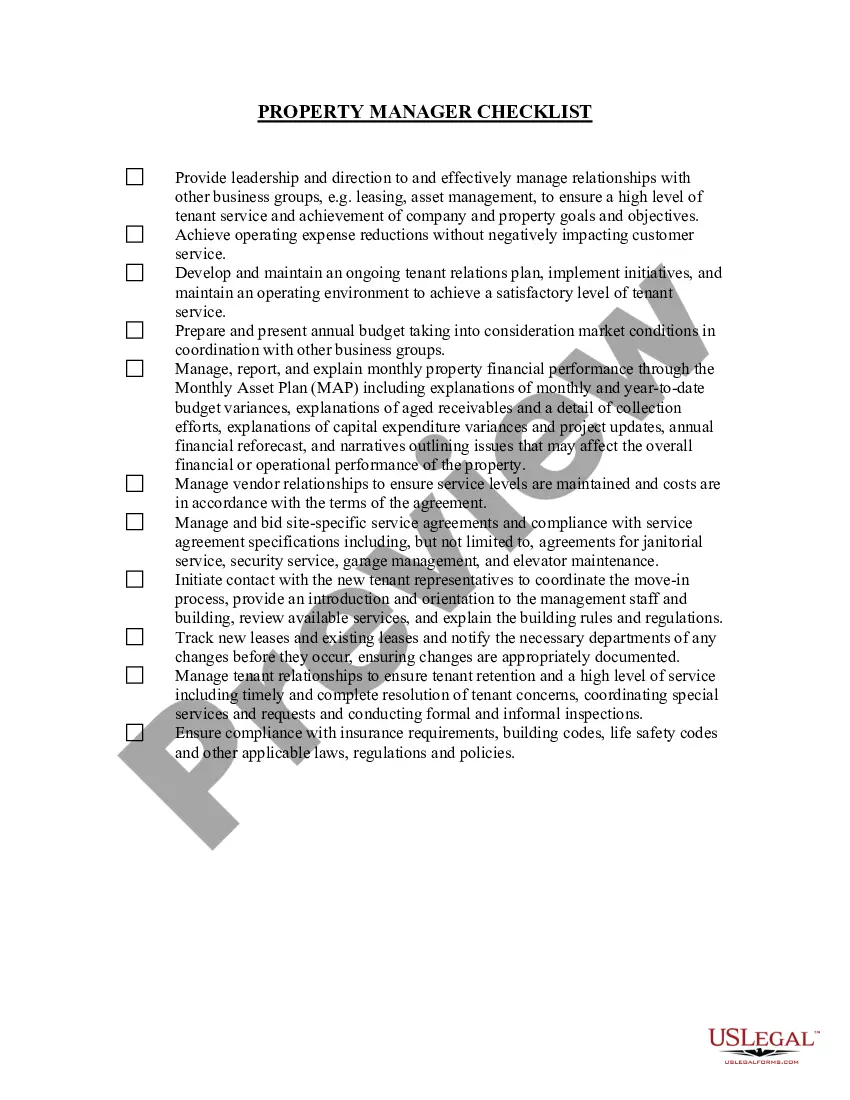

Wyoming Maintenance Supervisor Checklist

Description

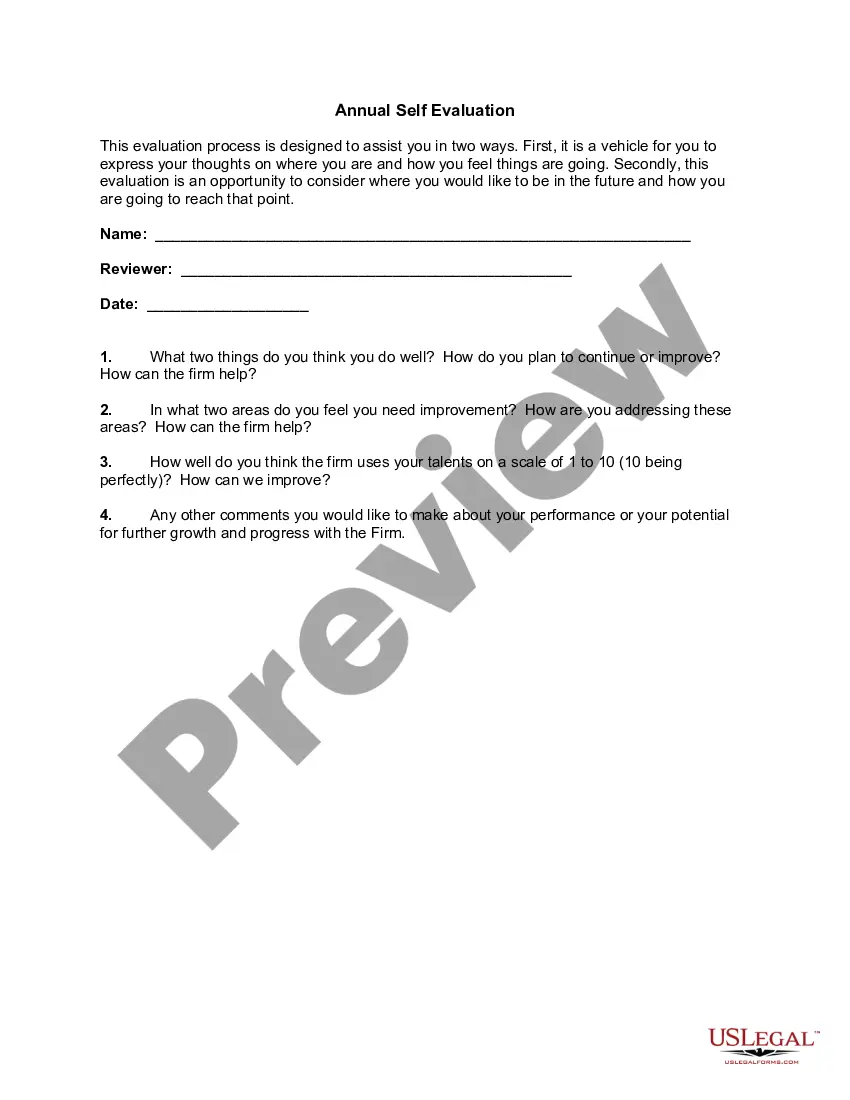

How to fill out Maintenance Supervisor Checklist?

Selecting the ideal legal document web template can be a challenge.

Of course, there are numerous web templates available online, but how do you locate the legal document you require? Utilize the US Legal Forms website.

The platform provides a wide array of web templates, including the Wyoming Maintenance Supervisor Checklist, which can be utilized for both business and personal purposes. All forms are reviewed by professionals and comply with federal and state regulations.

If the form does not fulfill your needs, use the Search field to find the appropriate form. Once you are confident that the form is correct, click on the Buy now button to obtain the form. Select the pricing option you prefer and enter the necessary details. Create your account and complete the purchase using your PayPal account or credit card. Choose the document format and download the legal document web template to your device. Finally, complete, modify, and print the obtained Wyoming Maintenance Supervisor Checklist, then sign it. US Legal Forms is the largest collection of legal forms where you can find various document templates. Use the service to obtain professionally crafted documents that adhere to state regulations.

- If you are already registered, sign in to your account and click on the Download button to acquire the Wyoming Maintenance Supervisor Checklist.

- Use your account to search for the legal documents you have previously purchased.

- Go to the My documents section of your account to download another copy of the document you need.

- If you are a new user of US Legal Forms, here are straightforward steps for you to follow.

- First, ensure you have selected the right form for your city/state.

- You can review the form using the Preview button and check the form description to confirm it is the correct one for you.

Form popularity

FAQ

Maintenance managers oversee a team of maintenance supervisors who manage technicians and workload during a particular shift. Depending on the size of the organization, managers report to either a maintenance director, president, or vice president of operations.

Here Are the 8 Skills Every Maintenance Manager Needs to Master to be SuccessfulLeadership. Maintenance managers need to exhibit leadership capability.Good Interpersonal Skills.Time Management.Know How to Groom Individuals.Problem Solving Skills.Flexibility.Team Work.Technical Expertise.16-May-2018

On a typical workday, you will find maintenance supervisors working primarily with the technicians and other employees on duty. They must lead and motivate the team and delegate tasks accordingly. They may report to a maintenance manager, facilities manager, maintenance director, or some other executive.

Qualities of a Good Maintenance ManagerDignity and respect for his superiors, team, vendors, and guests. Mentor to his team. Attentive, supportive, and responsive to team needs. Confident in his abilities.

Important Skills for Maintenance ProfessionalsTechnical Expertise.Interpersonal Skills.Problem Solving and Analytical Skills.Adaptability.Time Management Skills.Teamwork and Collaboration.Ability to Cope with Stress.

A maintenance supervisor coordinates the installation, maintenance and repair work in buildings or large complexes. They manage a team of workers, regularly inspect sites, execute work as necessary, maintain equipment and assign workers to various projects. Completely free trial, no card required.

What does a Maintenance Manager do? Maintenance Managers oversee and lead maintenance procedures in a company. They manage activities such as tracking expenses and report progress updates to owners or higher-ups. They also handle specific tasks assigned to them along the way.

A maintenance supervisor is usually only in charge of the team of people that work under him, while a maintenance manager is in charge of the employees, equipment and often resources allocated to the maintenance faculty of a building or organization.

A maintenance supervisor coordinates the installation, maintenance and repair work in buildings or large complexes. They manage a team of workers, regularly inspect sites, execute work as necessary, maintain equipment and assign workers to various projects.

In general, managers earn more than supervisors do. This is because managers generally have more responsibility, which gives them a higher level of authority. They have more responsibilities because of their role as strategic planners for the company. Managers in the U.S. earn an average of $55,342 per year.