Title: Wyoming Equipment Maintenance Agreement with a Systems Integrator: Comprehensive Guide for Effective Equipment Management Introduction: Wyoming Equipment Maintenance Agreements with Systems Integrators offer businesses in various industries a comprehensive solution for equipment upkeep and seamless system integration. This detailed description aims to provide insights into the importance, benefits, and key elements of such agreements while highlighting different types available in Wyoming. Key terms and keywords: Wyoming, Equipment Maintenance Agreement, Systems Integrator, equipment management, seamless system integration, benefits, key elements. 1. Understanding the Equipment Maintenance Agreement: An Equipment Maintenance Agreement (EMA) in Wyoming creates a formal contract between an organization and a Systems Integrator, detailing responsibilities, expectations, and terms related to equipment maintenance, repairs, and system integration services. 2. Importance and Benefits of an EMA: By entering into an Equipment Maintenance Agreement with a Systems Integrator, businesses in Wyoming gain access to numerous advantages: — Increased Equipment Reliability: Regular maintenance and prompt repairs ensure equipment functions optimally, minimizing downtime. — Expertise and Technical Support: Systems Integrators possess specialized knowledge, experience, and resources for effective equipment management. Predictabilityty EMAMA'sAs often provide predictable costs for maintenance and repairs, allowing businesses to budget accordingly. — Enhanced Efficiency: A well-maintained and integrated system improves workflow, productivity, and overall operational efficiency. — Cost Savings: Timely repairs and preventative maintenance can help avoid costly breakdowns or equipment replacements. 3. Key Elements of a Wyoming EMA: While various provisions can be included, key elements typically found in an Equipment Maintenance Agreement with a Systems Integrator in Wyoming include: — Scope of Services: Clearly defining the equipment covered, maintenance tasks, and system integration services. — Response Time: Agreement on the time frame within which the Systems Integrator must respond to repair requests or system integration needs. — Performance Measures: Outlining desired outcomes, benchmarks, or metrics to gauge equipment performance. — Service-Level Agreements (SLAs): Metrics to ensure the Systems Integrator meets agreed-upon service levels, such as maximum downtime, response time, etc. — Term and Termination: Duration of the agreement and the conditions under which either party may terminate the contract. — Payment Terms: Details regarding maintenance fees, payment schedules, and any penalties associated with late payments. 4. Types of Wyoming Equipment Maintenance Agreements: Depending on the specific requirements of a business, Wyoming offers a range of EMA's with Systems Integrators, including: — Preventative Maintenance Agreements (PMA's): Focuses on scheduled inspections, routine maintenance, and preemptive repairs to ensure equipment longevity. — Corrective MaintenancAgreementMAMAMSASAs): Primarily covers repairs after equipment breakdowns or malfunctions. — Comprehensive MaintenancAgreementMAMAMA'SAS): Encompasses both preventative and corrective maintenance, offering a holistic solution for equipment upkeep and system integration. Conclusion: Wyoming Equipment Maintenance Agreements with Systems Integrators present businesses with a comprehensive approach to equipment management, repair, and system integration. These agreements benefit organizations by ensuring equipment reliability, cost predictability, enhanced efficiency, and access to expertise. Understanding the key elements and types of EMA's available helps businesses choose the most suitable agreement for their unique needs.

Wyoming Equipment Maintenance Agreement with a Systems Integrator

Description

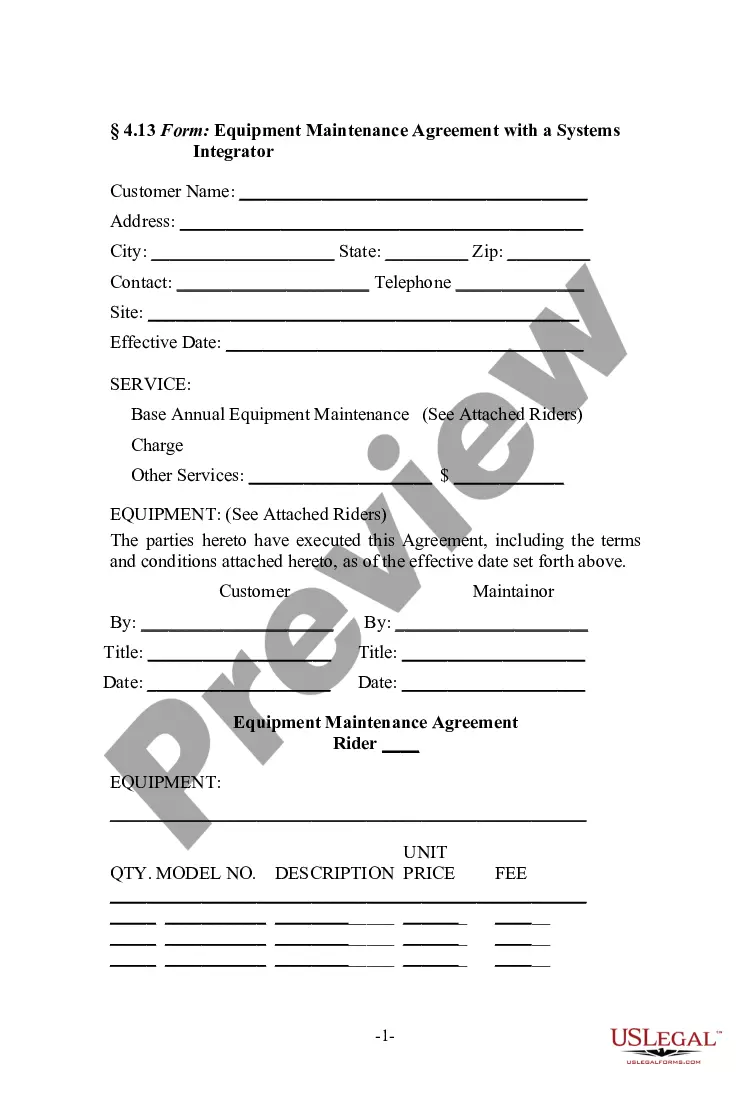

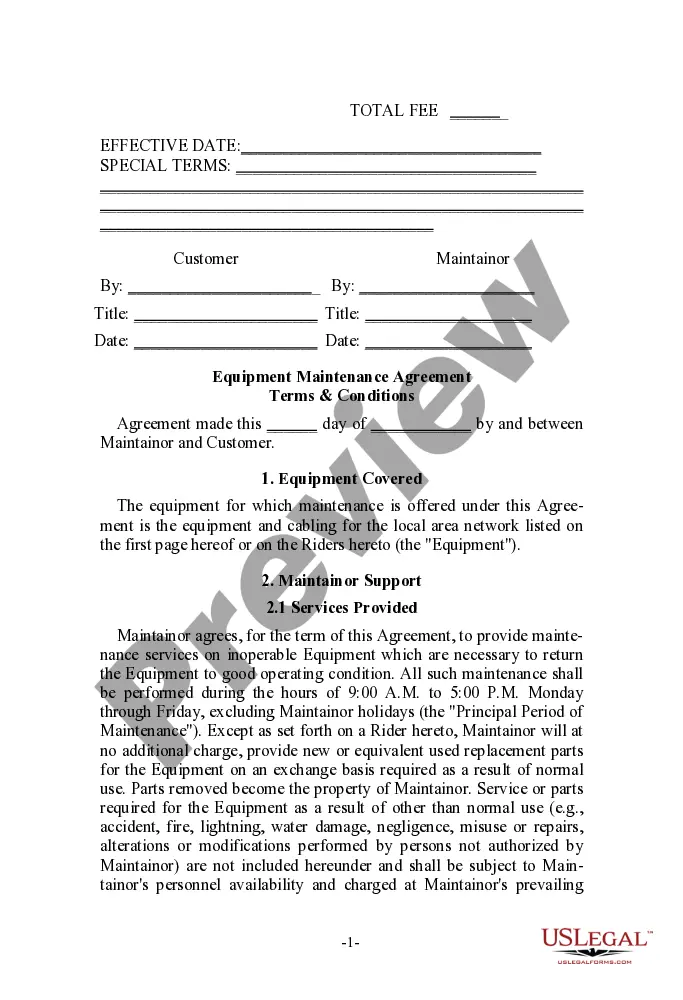

How to fill out Wyoming Equipment Maintenance Agreement With A Systems Integrator?

US Legal Forms - among the biggest libraries of authorized kinds in the USA - gives a wide range of authorized file layouts you can acquire or printing. Utilizing the internet site, you can get a large number of kinds for business and specific uses, categorized by groups, states, or key phrases.You can find the latest versions of kinds just like the Wyoming Equipment Maintenance Agreement with a Systems Integrator in seconds.

If you have a monthly subscription, log in and acquire Wyoming Equipment Maintenance Agreement with a Systems Integrator through the US Legal Forms library. The Download switch can look on every form you see. You have access to all in the past acquired kinds within the My Forms tab of your own accounts.

In order to use US Legal Forms the first time, listed here are straightforward instructions to obtain started:

- Ensure you have picked out the correct form for the metropolis/area. Click the Preview switch to examine the form`s content. Browse the form outline to ensure that you have chosen the right form.

- In the event the form does not satisfy your specifications, utilize the Search discipline at the top of the monitor to obtain the one that does.

- When you are satisfied with the form, verify your choice by clicking the Purchase now switch. Then, opt for the pricing prepare you favor and supply your credentials to register to have an accounts.

- Method the deal. Make use of credit card or PayPal accounts to finish the deal.

- Choose the structure and acquire the form on the product.

- Make alterations. Fill up, edit and printing and indication the acquired Wyoming Equipment Maintenance Agreement with a Systems Integrator.

Each and every template you added to your account lacks an expiry date and is also your own for a long time. So, in order to acquire or printing one more duplicate, just proceed to the My Forms area and click on in the form you will need.

Get access to the Wyoming Equipment Maintenance Agreement with a Systems Integrator with US Legal Forms, one of the most extensive library of authorized file layouts. Use a large number of specialist and condition-particular layouts that meet your business or specific needs and specifications.