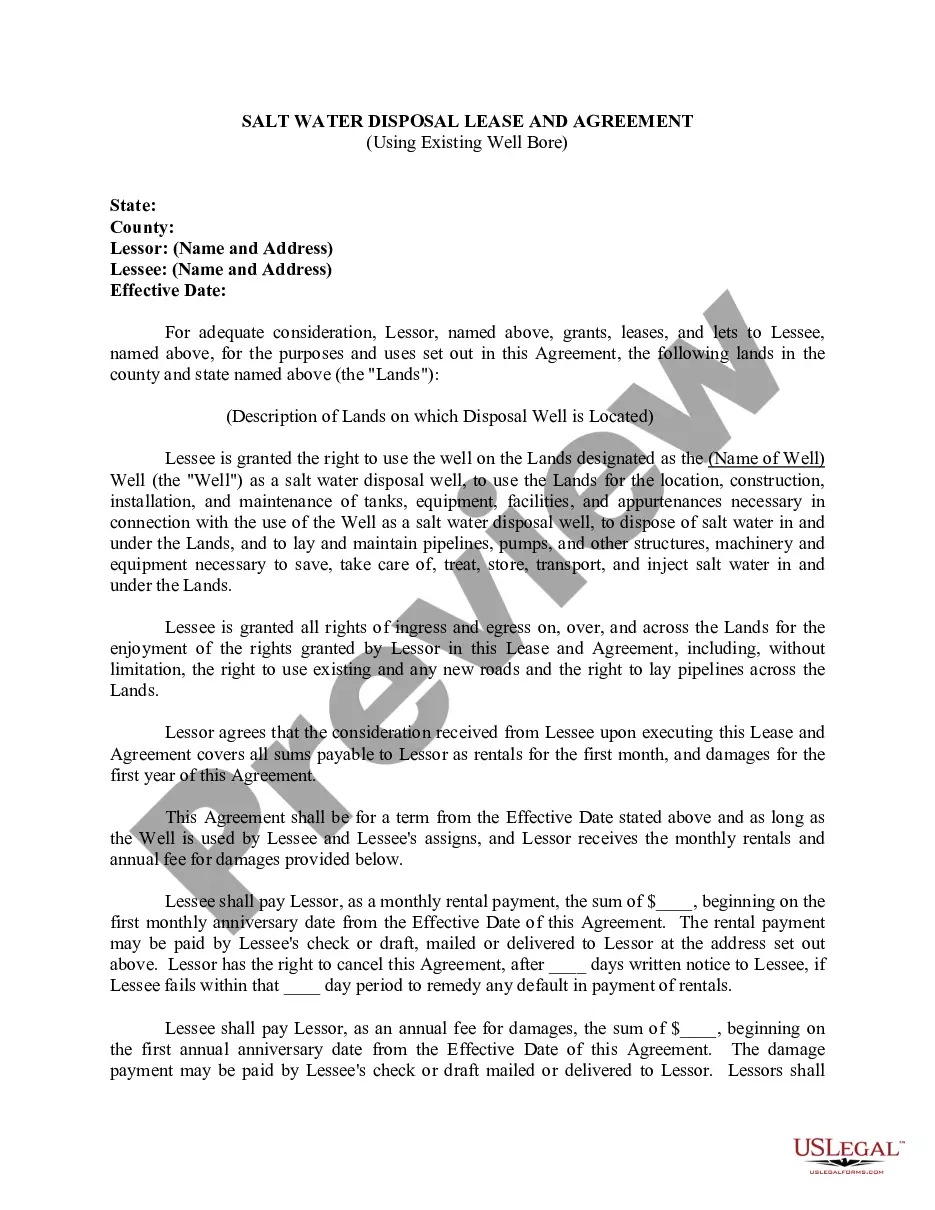

This lease rider form may be used when you are involved in a lease transaction, and have made the decision to utilize the form of Oil and Gas Lease presented to you by the Lessee, and you want to include additional provisions to that Lease form to address specific concerns you may have, or place limitations on the rights granted the Lessee in the standard lease form.

Wyoming Salt Water - Disposal, Storage, and Handling

Description

How to fill out Salt Water - Disposal, Storage, And Handling?

Choosing the best legitimate record format can be a battle. Of course, there are tons of layouts available online, but how will you discover the legitimate kind you require? Make use of the US Legal Forms internet site. The services provides thousands of layouts, such as the Wyoming Salt Water - Disposal, Storage, and Handling, which can be used for business and private needs. Every one of the varieties are checked out by pros and fulfill federal and state needs.

When you are currently signed up, log in to your profile and click on the Obtain option to get the Wyoming Salt Water - Disposal, Storage, and Handling. Make use of profile to search with the legitimate varieties you possess purchased previously. Go to the My Forms tab of your respective profile and acquire another backup in the record you require.

When you are a fresh end user of US Legal Forms, listed below are easy recommendations so that you can adhere to:

- Very first, be sure you have chosen the right kind for the area/county. It is possible to look through the form making use of the Preview option and look at the form explanation to ensure this is the right one for you.

- When the kind fails to fulfill your needs, utilize the Seach discipline to obtain the proper kind.

- When you are certain the form is proper, click on the Buy now option to get the kind.

- Pick the rates prepare you would like and enter the needed details. Design your profile and pay for the transaction utilizing your PayPal profile or charge card.

- Pick the data file file format and obtain the legitimate record format to your device.

- Complete, edit and print and sign the attained Wyoming Salt Water - Disposal, Storage, and Handling.

US Legal Forms may be the greatest collection of legitimate varieties that you can see numerous record layouts. Make use of the service to obtain appropriately-manufactured files that adhere to condition needs.

Form popularity

FAQ

A disposal well is often a depleted oil or gas well, into which waste fluids can be injected for safe disposal. A by-product of oil and gas production is water that was either trapped in the same deep formations, was injected to stimulate a formation (hydraulic fracturing), or was injected to enhance oil recovery.

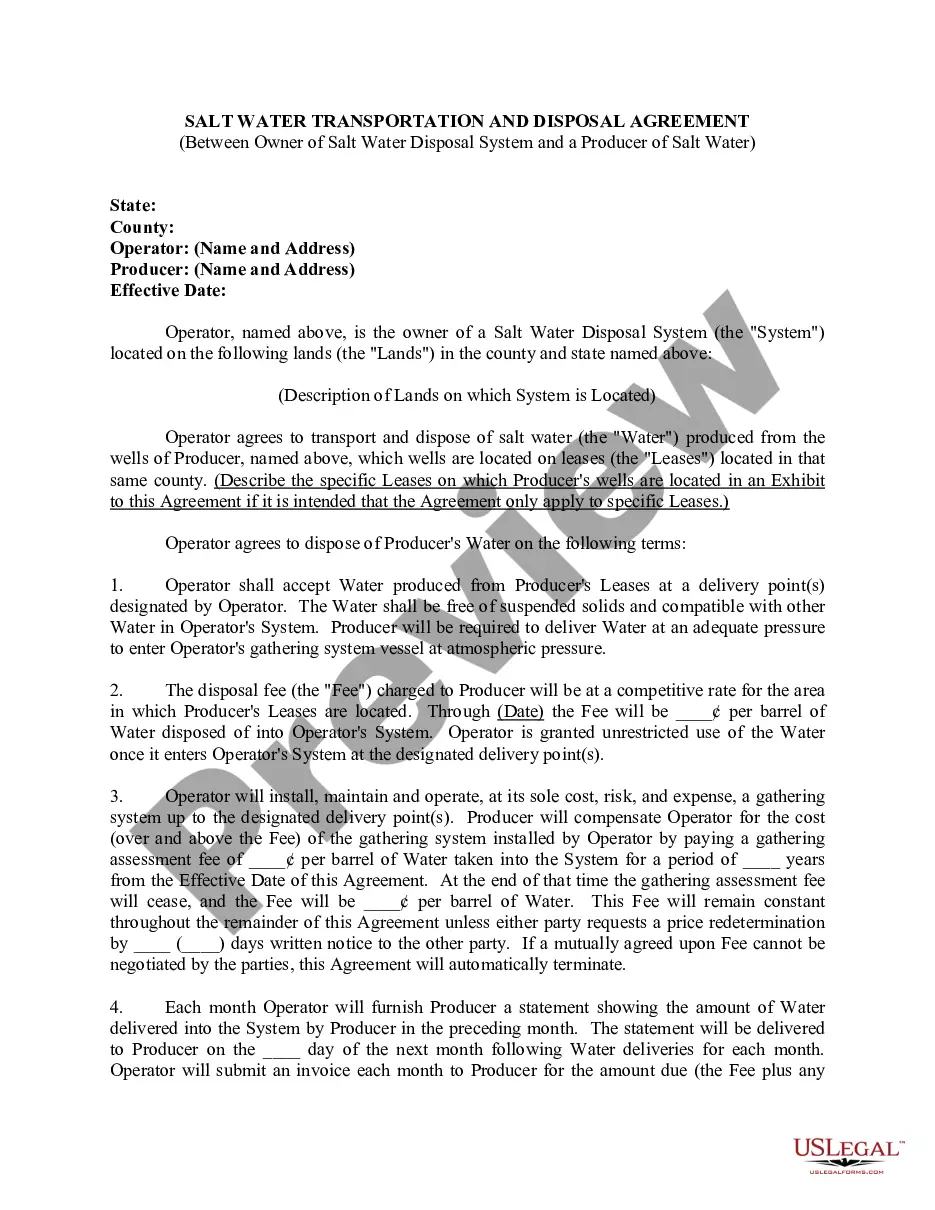

How Saltwater Disposal Works. Saltwater is typically ejected from the wells into natural underground formations sealed within an impenetrable rock to prevent the saltwater from escaping into surrounding soil and groundwater. What Is a Saltwater Disposal Well? - Treehugger TreeHugger ? Energy ? Fossil Fuels TreeHugger ? Energy ? Fossil Fuels

The process of oil and gas production creates millions of gallons of hazardous brine, also known as salt water, every day. This salt water contains various chemicals for extracting impurities out of the oil and gas and has an extremely high salt content, making it dangerous.

While some particularly arid regions allow for disposal via evaporation from large holding pits, most salt water is disposed of at specialty disposal sites where the salt water is injected by way of a disposal well (salt water disposal, or SWD wells) into natural underground formations.

A salt water disposal (SWD) well is a disposal site for water produced as a result of the oil and gas extraction process. Produced water, also referred to as salt water, contains particulate which can cause problems for the pump bringing water into the well.