Chicago Illinois Lease of Machinery for use in Manufacturing is a contract agreement entered into by manufacturing businesses in the city of Chicago, Illinois to avail themselves of machinery and equipment for their production processes on a lease basis. This arrangement provides manufacturing companies with the opportunity to access and use various types of machinery without having to purchase and maintain them outright. The lease of machinery for use in manufacturing is a common practice in Chicago, enabling businesses to expedite their operations and maintain a competitive edge in the industry. It allows companies to access advanced, specialized, and expensive machinery that may otherwise be financially burdensome for them to own. There are different types of Chicago Illinois Lease of Machinery for use in Manufacturing available to cater to the diverse needs of businesses. Some common types include: 1. Plant and Machinery Leasing: This type of lease agreement offers manufacturing businesses the opportunity to lease a wide range of heavy machinery and equipment needed for their production processes. This can include machinery such as construction equipment, industrial boilers, generators, and industrial ovens. 2. Equipment Leasing: This category of lease focuses on providing manufacturing companies with specific equipment required for their production processes. It can include leasing options for specialized machinery like CNC machines, robotic arms, conveyor belts, forklifts, and other automated production tools. 3. Tooling and Die Leasing: This type of lease offers manufacturing businesses access to essential tooling and die equipment used in various manufacturing operations such as metal stamping, injection molding, and precision engineering. It enables businesses to maintain quality production without incurring the high costs associated with purchasing and maintaining these tools. 4. Packaging Machinery Leasing: Manufacturing companies often require packaging equipment to streamline their product packing processes. This type of lease allows businesses to access packaging machinery like filling machines, labeling machines, sealing machines, and shrink-wrapping machines on a temporary or long-term basis. 5. Maintenance and Repair Services: Some leasing agreements in Chicago Illinois for machinery used in manufacturing also include provisions for regular maintenance, repairs, and technical support. This ensures that the leased machinery remains in optimal condition throughout the lease term, reducing downtime for the production processes. In conclusion, Chicago Illinois Lease of Machinery for use in Manufacturing is a vital aspect of the city's manufacturing sector. It offers diverse leasing options catering to different types of machinery required by businesses, enhancing their productivity and competitiveness. By leasing machinery instead of purchasing outright, manufacturing companies can focus on their core operations, reduce upfront costs, and adapt to evolving technological advancements in the industry.

Chicago Illinois Lease of Machinery for use in Manufacturing

Description

How to fill out Chicago Illinois Lease Of Machinery For Use In Manufacturing?

Preparing legal documentation can be burdensome. Besides, if you decide to ask a lawyer to write a commercial contract, papers for ownership transfer, pre-marital agreement, divorce papers, or the Chicago Lease of Machinery for use in Manufacturing, it may cost you a fortune. So what is the best way to save time and money and draft legitimate forms in total compliance with your state and local regulations? US Legal Forms is a perfect solution, whether you're looking for templates for your personal or business needs.

US Legal Forms is the most extensive online catalog of state-specific legal documents, providing users with the up-to-date and professionally verified forms for any use case accumulated all in one place. Therefore, if you need the current version of the Chicago Lease of Machinery for use in Manufacturing, you can easily locate it on our platform. Obtaining the papers takes a minimum of time. Those who already have an account should check their subscription to be valid, log in, and select the sample by clicking on the Download button. If you haven't subscribed yet, here's how you can get the Chicago Lease of Machinery for use in Manufacturing:

- Look through the page and verify there is a sample for your region.

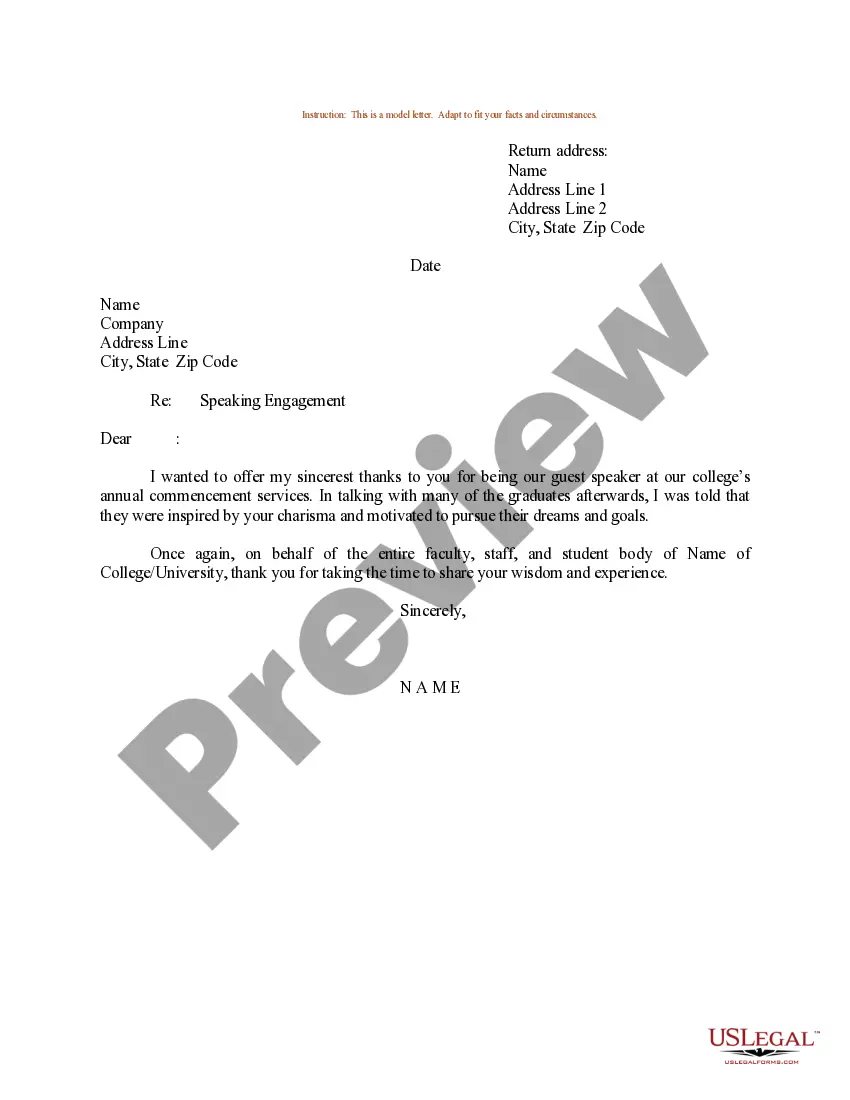

- Examine the form description and use the Preview option, if available, to make sure it's the template you need.

- Don't worry if the form doesn't suit your requirements - search for the right one in the header.

- Click Buy Now when you find the needed sample and pick the best suitable subscription.

- Log in or register for an account to purchase your subscription.

- Make a payment with a credit card or through PayPal.

- Opt for the file format for your Chicago Lease of Machinery for use in Manufacturing and download it.

Once done, you can print it out and complete it on paper or import the samples to an online editor for a faster and more convenient fill-out. US Legal Forms enables you to use all the documents ever acquired many times - you can find your templates in the My Forms tab in your profile. Give it a try now!