Chicago Illinois Manufacturer Analysis Checklist is a comprehensive tool used to evaluate and assess manufacturers operating in Chicago, Illinois. This checklist is crafted to aid businesses, researchers, and stakeholders in analyzing various facets of manufacturers to make informed decisions. By employing this checklist, one can effectively scrutinize manufacturers based on their capabilities, quality standards, production processes, sustainability practices, and competitiveness in the market. Keywords: Chicago Illinois, manufacturer analysis, checklist, evaluate, assess, capabilities, quality standards, production processes, sustainability practices, competitiveness. Different Types of Chicago Illinois Manufacturer Analysis Checklists: 1. Capability Assessment Checklist: This type of checklist focuses on evaluating the capabilities of manufacturers in Chicago, Illinois. It encompasses analyzing their production capacity, technological expertise, human resources, supply chain management, research and development capabilities, and financial stability. 2. Quality Standards Checklist: This checklist concentrates on assessing the quality standards maintained by manufacturers. It involves examining adherence to industry-specific quality certifications, compliance with regulatory requirements, product testing processes, and commitment to continuous improvement. 3. Production Process Analysis Checklist: This checklist enables a comprehensive assessment of the production processes employed by manufacturers. It includes evaluating factors such as raw material sourcing, inventory management, production efficiency, waste management practices, and utilization of advanced manufacturing technologies. 4. Sustainability Practices Checklist: With a growing focus on sustainability, this checklist evaluates manufacturers' efforts to operate in an environmentally responsible manner. It covers aspects like energy consumption, waste reduction, recycling initiatives, adoption of clean technologies, and social responsibility endeavors. 5. Competitiveness Evaluation Checklist: This checklist aims to assess the competitiveness of manufacturers in the Chicago, Illinois market. It entails analyzing factors like market share, pricing strategies, product differentiation, customer satisfaction, sales and marketing efforts, and ability to meet customer demands. 6. Supplier Evaluation Checklist: Focused specifically on manufacturers' relationships with suppliers, this checklist examines their supplier selection criteria, supplier performance tracking, supplier relationship management, negotiation strategies, and approach to supply chain optimization. By utilizing these different types of Chicago Illinois Manufacturer Analysis Checklists, businesses and researchers can have a comprehensive understanding of manufacturers operating in the region. This detailed evaluation helps in determining the most suitable partners for collaboration, identifying areas for improvement, and facilitating informed decision-making.

Chicago Illinois Manufacturer Analysis Checklist

Description

How to fill out Chicago Illinois Manufacturer Analysis Checklist?

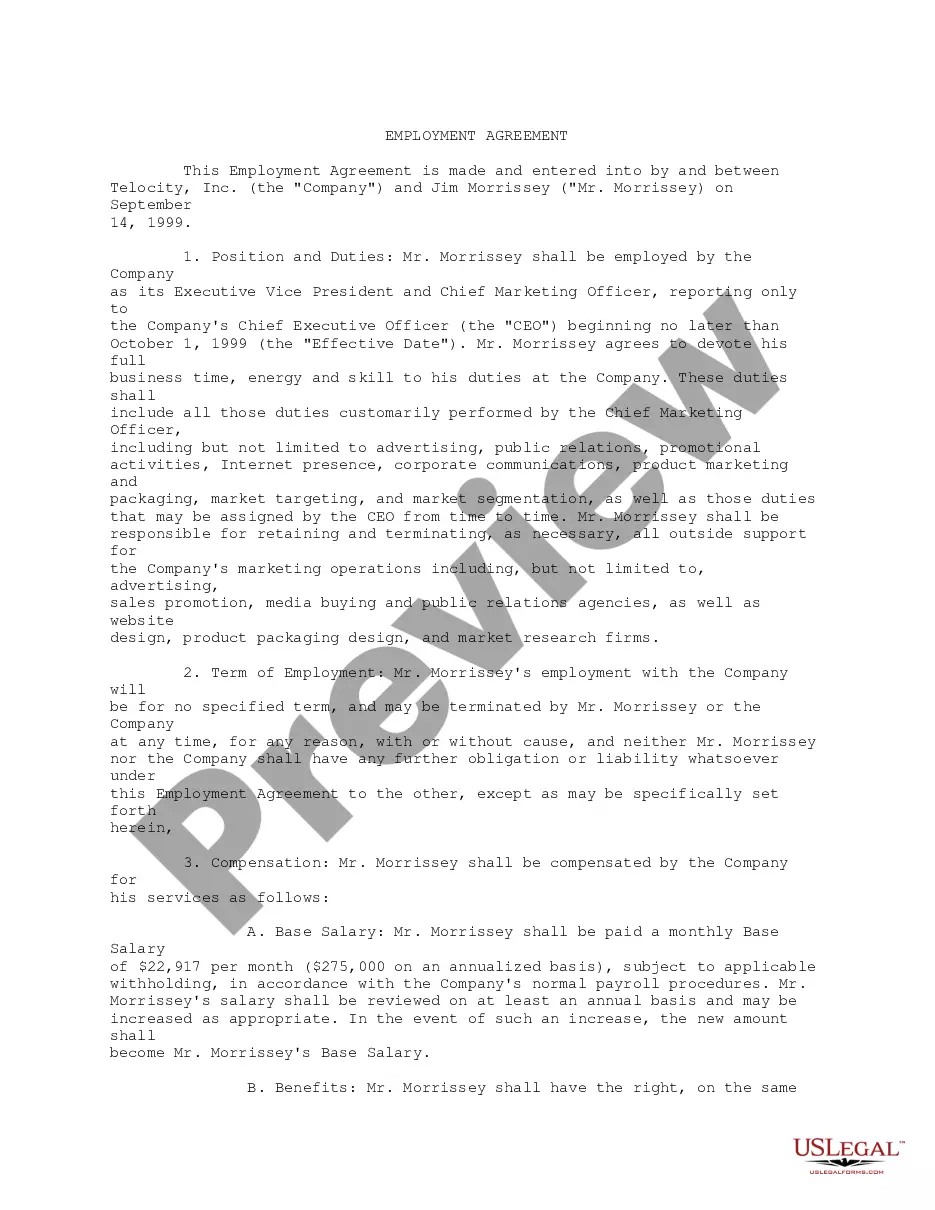

Are you looking to quickly draft a legally-binding Chicago Manufacturer Analysis Checklist or maybe any other form to take control of your personal or corporate matters? You can go with two options: contact a professional to write a valid document for you or draft it completely on your own. Thankfully, there's another option - US Legal Forms. It will help you get neatly written legal papers without paying sky-high fees for legal services.

US Legal Forms offers a rich collection of more than 85,000 state-compliant form templates, including Chicago Manufacturer Analysis Checklist and form packages. We provide documents for an array of life circumstances: from divorce papers to real estate document templates. We've been out there for over 25 years and gained a rock-solid reputation among our clients. Here's how you can become one of them and get the needed document without extra troubles.

- First and foremost, carefully verify if the Chicago Manufacturer Analysis Checklist is tailored to your state's or county's laws.

- In case the document has a desciption, make sure to check what it's intended for.

- Start the search over if the document isn’t what you were hoping to find by utilizing the search box in the header.

- Select the plan that best fits your needs and proceed to the payment.

- Select the format you would like to get your document in and download it.

- Print it out, complete it, and sign on the dotted line.

If you've already set up an account, you can simply log in to it, locate the Chicago Manufacturer Analysis Checklist template, and download it. To re-download the form, just head to the My Forms tab.

It's stressless to buy and download legal forms if you use our catalog. In addition, the paperwork we offer are reviewed by industry experts, which gives you greater peace of mind when dealing with legal affairs. Try US Legal Forms now and see for yourself!