A Strategy for Research and Development

Research and development (R & D) needs to be carefully planned and managed to succeed. It is easy to waste money on developing ideas that go nowhere, but getting it right can lead to business stability, security and long-term profits.

Planning

R & D should be included in your overall business plan. The plan should illustrate the direction you want the business to take and how R & D fits in with your other business activities. Set out clear objectives, time frames and budgets. A clear plan can prevent the project straying from your business goals and wasting valuable resources and money.

You may need to involve staff with specific skills to draw up the plan, for example finance staff to set up budgets. You may also need outside help.

Your plan should set out the steps that need to be taken from the inception of the ideas to the product launch. You should allocate the necessary resources to the project, including funding, staff and time. You might decide to set up a specific team to work on the project.

Management

Good management is vital to reduce risk of failure and realize as many ideas as possible.

To manage R & D projects effectively you should:

" Make sure staff involved in R & D understand the business' overall strategy;

" Ensure these employees understand what is commercially realistic;

" Assess the changing risks and potential of projects as they progress, continually developing a rigorous business case;

" Ensure that intellectual property ownership issues are resolved;

" Recognize when a project isn't going to work; and

" Understand the relative importance of different projects to your business.

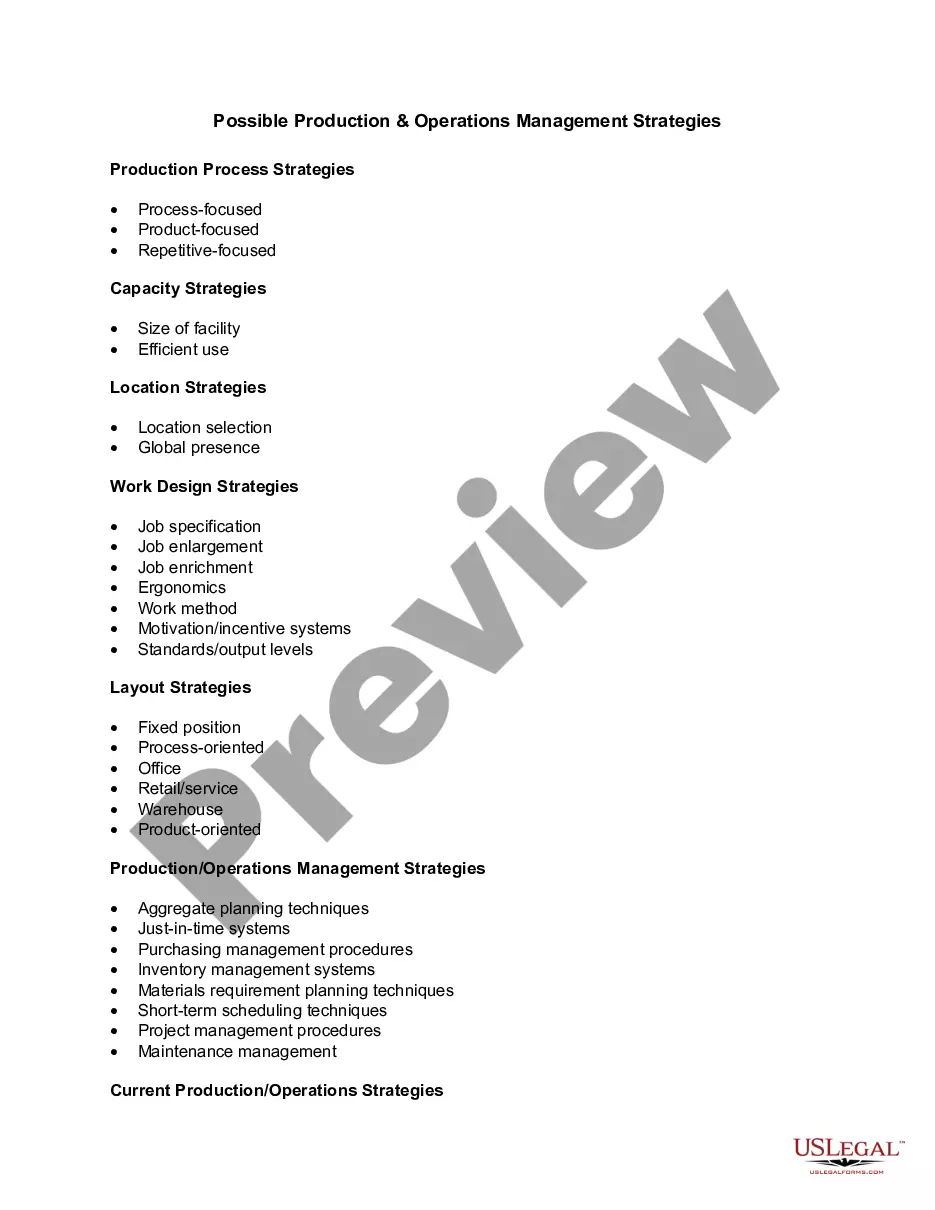

Houston, Texas, is a vibrant and dynamic city known for its robust industrial and manufacturing sector. As such, implementing effective production and operations management strategies is crucial for businesses operating in the region. In this article, we will delve into the possible production and operations management strategies that can be applied in Houston, Texas, to enhance productivity, streamline operations, and gain a competitive edge. 1. Lean Manufacturing Strategy: Lean manufacturing is a widely adopted approach that focuses on reducing waste, improving efficiency, and optimizing resources. In Houston, where numerous manufacturing companies thrive, implementing lean principles can drive continuous improvement and maximize profitability. Key aspects of this strategy include just-in-time inventory management, eliminating bottlenecks, and reducing setup times to enhance overall operational efficiency. 2. Total Quality Management (TQM): Total Quality Management emphasizes achieving customer satisfaction by continually improving product quality. By implementing TQM principles in Houston businesses, organizations can enhance reliability, reduce defects, and improve customer loyalty in a highly competitive market. TQM involves rigorous quality control processes, employee involvement, and a customer-centric approach to meet and exceed customer expectations. 3. Six Sigma Methodology: Six Sigma is a data-driven approach that aims to minimize defects and enhance process consistency. By implementing Six Sigma techniques in operations and production management, Houston businesses can attain exceptional quality levels and achieve operational excellence. The strategy involves defining, measuring, analyzing, improving, and controlling processes to achieve near-perfect results, ultimately leading to increased customer satisfaction and reduced costs. 4. Supply Chain Integration: Given Houston's role as a major transportation hub and its proximity to the Gulf of Mexico, supply chain integration is crucial for businesses operating in the region. By integrating suppliers, manufacturers, and distributors, companies can improve coordination, reduce lead times, and achieve cost efficiencies. Employing advanced technologies, such as electronic data interchange (EDI) and enterprise resource planning (ERP) systems, facilitates smoother supply chain management and fosters effective collaboration. 5. Automation and Technology Integration: To keep pace with the technological advancements prevalent in Houston, businesses can adopt automation and technology integration strategies. Automation can help streamline operations, reduce errors, and improve production efficiency. Robotics, artificial intelligence, and smart manufacturing technologies are increasingly being employed to optimize tasks, enhance worker safety, and achieve higher productivity levels. 6. Environmental Sustainability Measures: In line with efforts to reduce environmental impact, Houston-based businesses can implement production and operations management strategies that prioritize sustainability. This could involve adopting eco-friendly manufacturing processes, utilizing renewable energy sources, and reducing waste generation. By aligning their operations with sustainability goals, companies can attract a growing number of environmentally conscious customers and improve their brand image. 7. Capacity Planning and Resource Allocation: Houston's diverse industrial landscape demands effective capacity planning and resource allocation strategies. Businesses need to analyze demand patterns, forecast future requirements, and allocate resources optimally to match production needs. By implementing effective capacity planning techniques, such as aggregate planning and resource leveling, companies can minimize bottlenecks, improve delivery times, and reduce costs associated with underutilized resources. By implementing these production and operations management strategies, Houston-based businesses can increase their operational efficiency, quality, and customer satisfaction. Each strategy addresses specific operational challenges while emphasizing the importance of optimizing resources, reducing waste, and adapting to changing market dynamics. Through the adoption of these strategies, companies can navigate Houston's competitive landscape and thrive in one of America's most industrious cities.