Middlesex Massachusetts Aeseptic Techniques

Description

How to fill out Aeseptic Techniques?

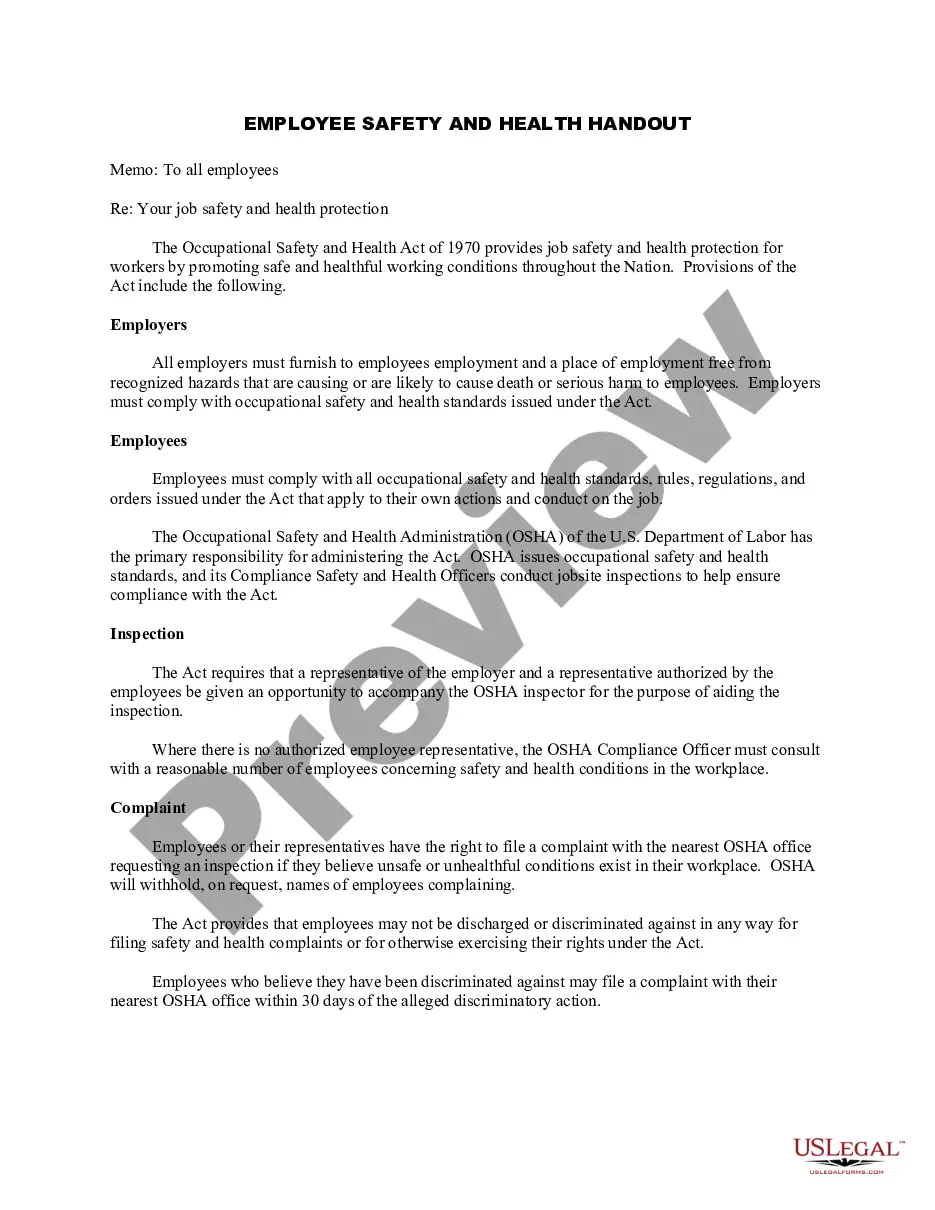

Creating documents for either a business or an individual request is always a significant obligation.

When drafting a contract, a public service appeal, or a power of attorney, it's critical to consider all federal and state laws relevant to the specific area.

However, minor counties and even municipalities also have legislative protocols that you must factor in.

The remarkable aspect of the US Legal Forms library is that all documents you have ever obtained remain accessible – you can retrieve them in your profile under the My documents section at any moment. Enroll in the platform and effortlessly acquire validated legal forms for any situation with just a few clicks!

- All these factors render it stressful and time-consuming to produce Middlesex Aseptic Techniques without professional assistance.

- It's simple to bypass expenditures on attorneys by preparing your documents and creating a legally enforceable Middlesex Aseptic Techniques independently, utilizing the US Legal Forms online library.

- It is the most extensive digital repository of state-specific legal paperwork that is expertly verified, so you can trust their legitimacy when selecting a template for your county.

- Previously registered users only need to Log In to their accounts to access the required document.

- If you do not have a subscription yet, follow the instructions below to acquire the Middlesex Aseptic Techniques.

- Review the page you’ve opened and verify if it contains the document you are looking for.

- To accomplish this, utilize the form description and preview if those features are available.

Form popularity

FAQ

The elements of aseptic technique are a sterile work area, good personal hygiene, sterile reagents and media, and sterile handling.

Healthcare professionals use aseptic technique when they are: performing surgical procedures. performing biopsies. dressing surgical wounds or burns. suturing wounds. inserting a urinary catheter, wound drain, intravenous line, or chest tube. administering injections. using instruments to conduct a vaginal examination.

Procedures that involve aseptic technique include: 200cInserting PICC lines. 200cPerforming dialysis. 200cInserting catheters. 200cRunning IVs. 200cInserting chest tubes. 200cPerforming surgeries. 200cDressing wounds.

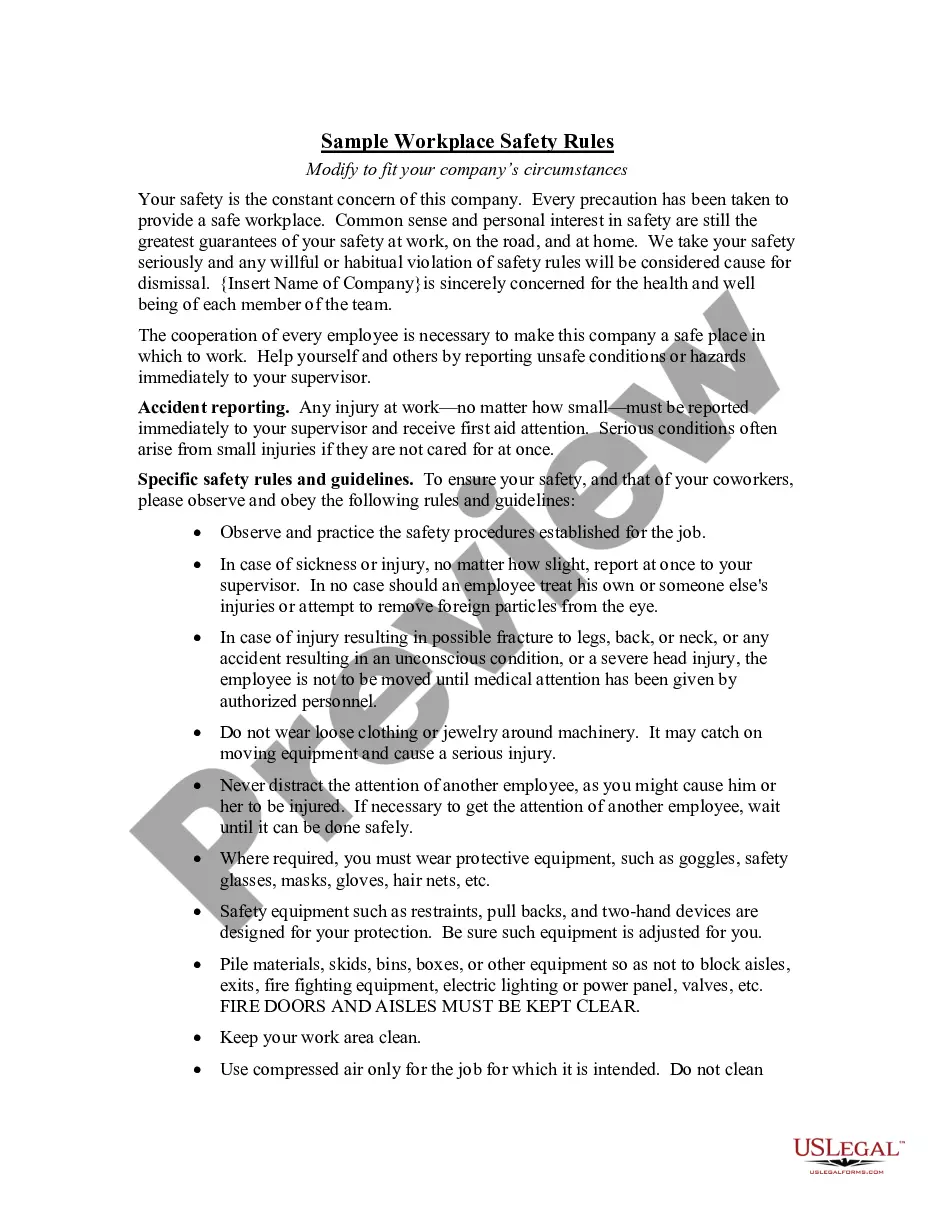

To make sure an area is free from germs, aseptic technique uses four strategies to keep things clean: 200cBarriers. A barrier is a physical, sterile object that prevents any germs on the healthcare professionals from getting on the patient.200cContact guidelines.200cTool and patient preparation.200cEnvironmental controls.

What is the difference between sterile and aseptic technique? Aseptic technique is intended to minimize contamination from pathogens. Sterile technique, on the other hand, is used to create an area free from any microorganisms, pathogenic or otherwise.

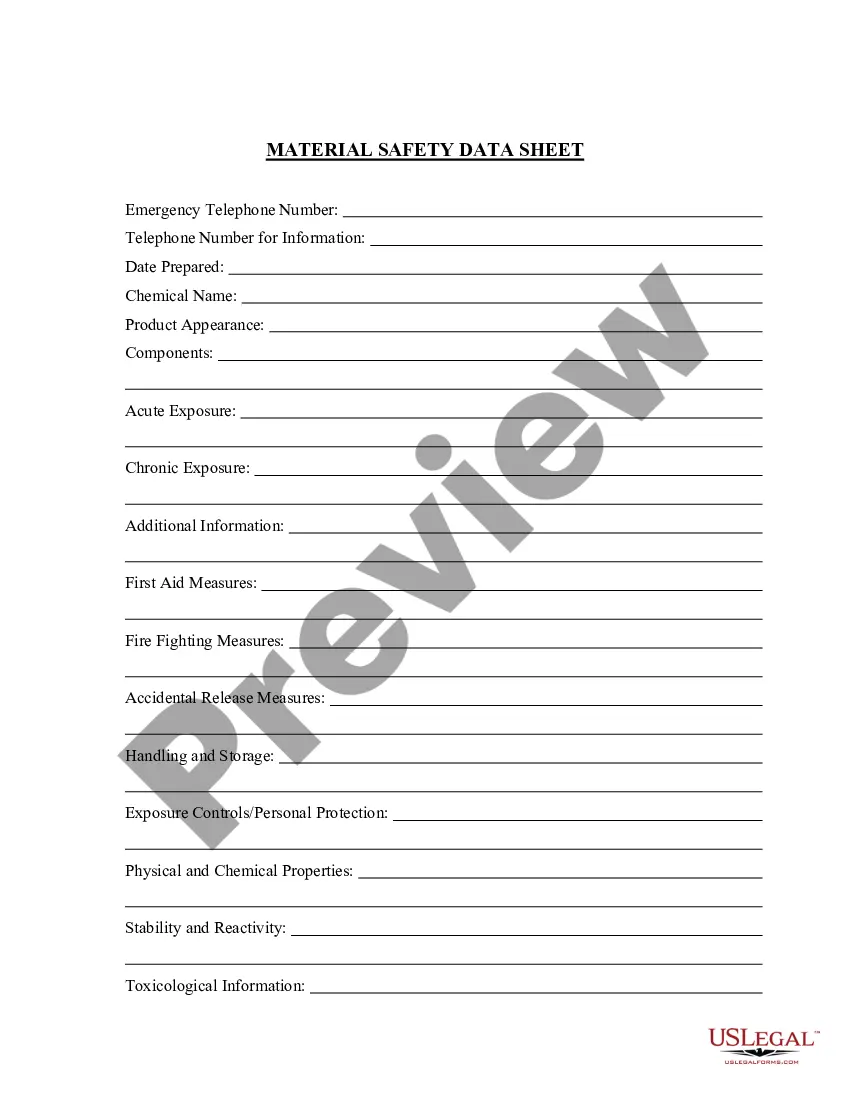

Sterile handling Always wipe your hands and your work area with 70% ethanol. Wipe the outside of the containers, flasks, plates, and dishes with 70% ethanol before placing them in the cell culture hood. Avoid pouring media and reagents directly from bottles or flasks.

ANTT is supported by evidence and highlights the key components involved in maintaining asepsis and aims to standardise practice. The underlying principles of ANTT are: Always wash hands effectively; Never contaminate key parts; Touch non-key parts with confidence; Take appropriate infective precautions.

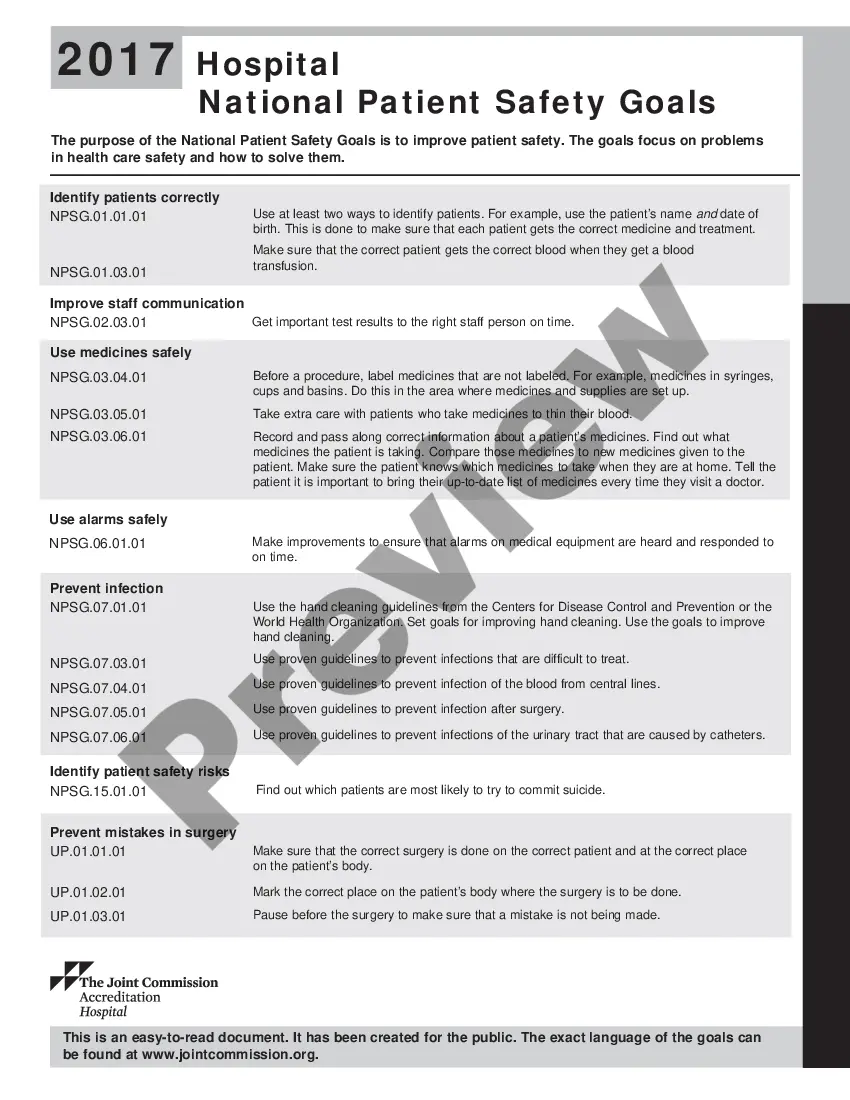

According to The Joint Commission, there are four chief aspects of the aseptic technique: barriers, patient equipment and preparation, environmental controls, and contact guidelines. Each plays an important role in infection prevention during a medical procedure.

Types of Aseptic Techniques Sterile technique. The strictest form of aseptic technique, sterile technique is intended to provide a space that has no germs whatsoever.Surgical aseptic technique. This is a strict form of aseptic technique that can be used outside the operating room.Standard aseptic technique.