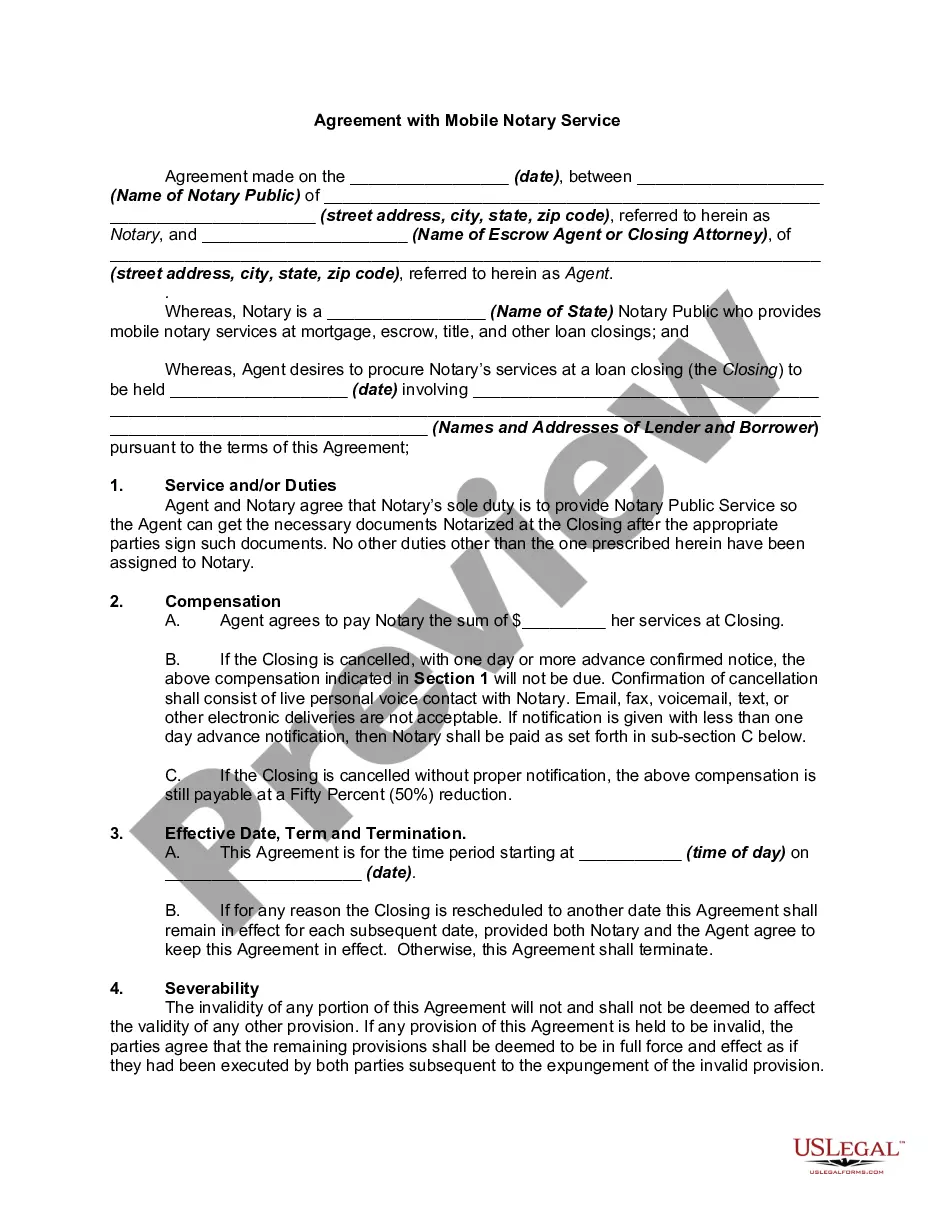

Wake North Carolina Aseptic Techniques play a crucial role in maintaining a sterile and contamination-free environment in various industries. These techniques follow stringent practices to prevent the introduction of microorganisms, pathogens, or any other contaminants during the manufacturing or handling processes. By implementing Wake North Carolina Aseptic Techniques, companies ensure the safety, purity, and efficacy of their products while meeting regulatory standards. Although there are various types of aseptic techniques, the most commonly used techniques include: 1. Sterile gowning: This technique involves wearing specialized garments, such as sterile gowns, gloves, masks, and shoe covers, to prevent the shedding of skin cells, hair, or any other contaminants that could compromise the sterile environment. Proper gowning procedures are followed, including sterilizing hands and donning the gown in a controlled area. 2. Sterile processing: This technique focuses on ensuring the sterility of equipment, instruments, and containers used in manufacturing or laboratory settings. It involves meticulous cleaning, sterilization, and monitoring procedures to eliminate any potential microbial contamination. 3. Environmental monitoring: Wake North Carolina Aseptic Techniques also include regular monitoring of the manufacturing or laboratory environment to assess and control the microbial contamination levels. This involves taking air, surface, and personnel samples to detect any potential sources of contamination and taking appropriate corrective actions. 4. Disinfection and sanitization: Proper cleaning, disinfection, and sanitization protocols are vital components of aseptic techniques. Specific agents and procedures are employed to eliminate or reduce microbial contamination on surfaces, equipment, or instruments. This ensures that the manufacturing environment remains free from any potential sources of contamination. 5. Aseptic processing: Aseptic processing techniques are utilized during the production of sterile pharmaceuticals, biologics, or parenteral products. It involves the use of sterile components, equipment, and environments to prevent any contamination during formulation, filling, and sealing processes. 6. Media fills: This technique simulates the entire aseptic manufacturing process using a sterile growth medium instead of actual products. It is performed as a validation test to assess the capability of the aseptic processing techniques and to detect or prevent any contamination events during the actual production. In conclusion, Wake North Carolina Aseptic Techniques are a set of practices and procedures implemented to maintain a sterile environment and prevent contamination in various industries. By employing techniques such as sterile gowning, sterile processing, environmental monitoring, disinfection and sanitization, aseptic processing, and media fills, companies ensure the safety and purity of their products while complying with regulatory standards.

Wake North Carolina Aeseptic Techniques

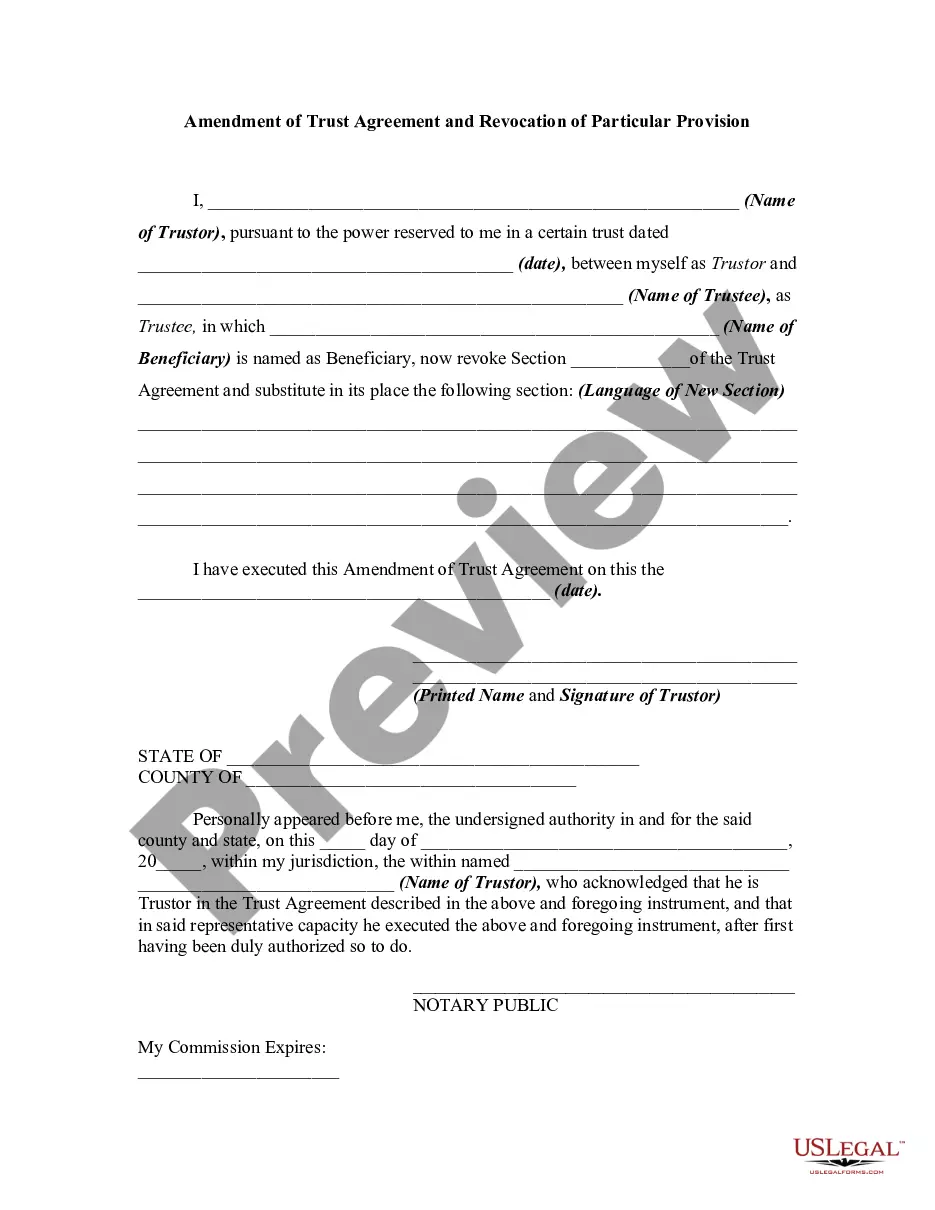

Description

How to fill out Wake North Carolina Aeseptic Techniques?

Preparing papers for the business or personal needs is always a big responsibility. When drawing up a contract, a public service request, or a power of attorney, it's important to take into account all federal and state laws of the specific region. Nevertheless, small counties and even cities also have legislative procedures that you need to consider. All these details make it burdensome and time-consuming to create Wake Aeseptic Techniques without professional help.

It's easy to avoid spending money on lawyers drafting your documentation and create a legally valid Wake Aeseptic Techniques by yourself, using the US Legal Forms online library. It is the largest online collection of state-specific legal documents that are professionally cheched, so you can be certain of their validity when picking a sample for your county. Earlier subscribed users only need to log in to their accounts to save the needed form.

If you still don't have a subscription, adhere to the step-by-step instruction below to obtain the Wake Aeseptic Techniques:

- Look through the page you've opened and verify if it has the sample you need.

- To do so, use the form description and preview if these options are presented.

- To locate the one that meets your needs, use the search tab in the page header.

- Double-check that the sample complies with juridical criteria and click Buy Now.

- Opt for the subscription plan, then sign in or register for an account with the US Legal Forms.

- Use your credit card or PayPal account to pay for your subscription.

- Download the selected file in the preferred format, print it, or fill it out electronically.

The great thing about the US Legal Forms library is that all the documentation you've ever obtained never gets lost - you can access it in your profile within the My Forms tab at any time. Join the platform and quickly get verified legal forms for any scenario with just a few clicks!