Chicago Illinois Equipment Maintenance Agreement with a Manufacturer: A Comprehensive Guide An Equipment Maintenance Agreement with a Manufacturer is a legal contract entered into by a company or organization in Chicago, Illinois, and a manufacturer to ensure continuous and efficient maintenance of equipment. This agreement establishes the terms and conditions for the maintenance and repair services provided by the manufacturer, ensuring that the equipment functions optimally for an extended period. Keywords: Equipment Maintenance Agreement, Chicago Illinois, Manufacturer, Maintenance, Repair Services Benefits of an Equipment Maintenance Agreement: 1. Cost Savings: By signing an Equipment Maintenance Agreement, businesses in Chicago can benefit from cost savings in the long run. Regular maintenance and proactive repairs ensure the equipment operates at peak performance, reducing the risk of costly breakdowns or replacements. 2. Increased Equipment Lifespan: Regular maintenance performed by the manufacturer helps extend the lifespan of equipment, ensuring its longevity. This can be particularly crucial for expensive, specialized machinery. 3. Minimized Downtime: With a designated maintenance schedule outlined in the agreement, businesses can minimize equipment downtime and avoid disruptions to their operations. Prompt repairs and maintenance prevent unexpected breakdowns and keep production running smoothly. 4. Expert Technical Support: The manufacturer possesses in-depth knowledge of their own equipment, making them the best choice for maintenance and repairs. Their expertise ensures that any issues are correctly diagnosed and efficiently addressed, reducing the risk of further damage. 5. Warranty Protection: An Equipment Maintenance Agreement often supplements existing warranties, offering additional protection against defects or failures. This provision can save businesses money on unforeseen repairs or replacement parts. Types of Equipment Maintenance Agreements: 1. Comprehensive Agreement: This type of agreement covers all aspects of equipment maintenance, including routine inspections, servicing, repairs, and spare parts. It offers businesses in Chicago a comprehensive solution to ensure their equipment's optimal performance. 2. Preventive Maintenance Agreement: A Preventive Maintenance Agreement outlines a regular service schedule for the equipment, focusing primarily on preventive measures such as inspections, cleaning, and minor adjustments. This type of agreement aims to identify potential issues before they become major problems. 3. Emergency Breakdown Agreement: An Emergency Breakdown Agreement primarily addresses unforeseen breakdowns or emergencies where immediate repairs are required. It typically includes provisions for a fast response time and priority service to minimize downtime. Key Considerations in a Chicago Illinois Equipment Maintenance Agreement: 1. Scope of Work: Clearly define the scope of maintenance services to be provided, whether routine inspections, repairs, or spare parts supply. 2. Service Levels: Specify the expected service response time and resolution for maintenance requests or equipment breakdowns. 3. Payment Terms: Outline the payment structure, including service charges, spare parts costs, and payment schedules. 4. Termination Clause: Include provisions for terminating the agreement if either party fails to fulfill their obligations or breaches the terms. 5. Intellectual Property Rights: Clarify ownership of any improvements, modifications, or inventions arising during the maintenance process. 6. Governing Law: Specify that the agreement is governed by the laws of Chicago, Illinois, ensuring its adherence to local regulations. In conclusion, an Equipment Maintenance Agreement with a Manufacturer in Chicago, Illinois, is a valuable tool to ensure seamless and efficient equipment maintenance. By signing such an agreement, businesses can benefit from regular maintenance, timely repairs, increased equipment lifespan, reduced downtime, and expert technical support.

Chicago Illinois Equipment Maintenance Agreement with a Manufacturer

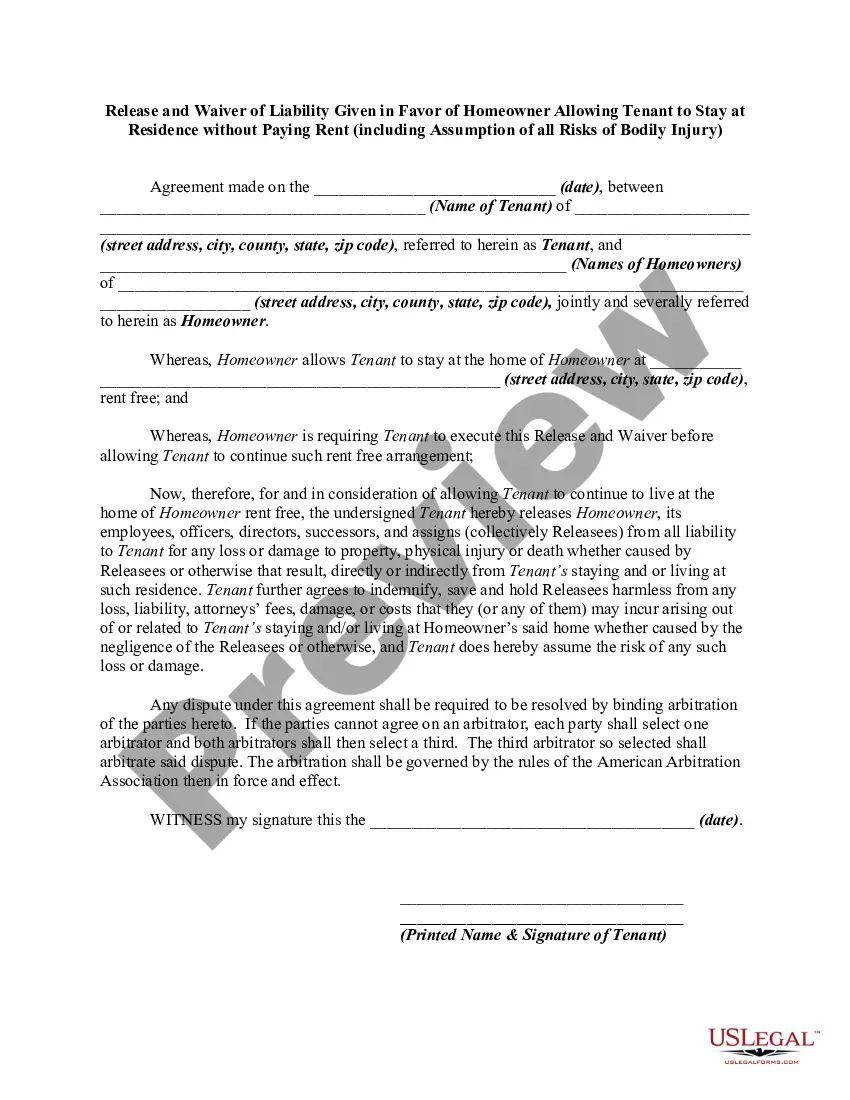

Description

How to fill out Chicago Illinois Equipment Maintenance Agreement With A Manufacturer?

Draftwing documents, like Chicago Equipment Maintenance Agreement with a Manufacturer, to take care of your legal matters is a difficult and time-consumming task. Many cases require an attorney’s involvement, which also makes this task expensive. However, you can take your legal issues into your own hands and handle them yourself. US Legal Forms is here to save the day. Our website features more than 85,000 legal documents crafted for a variety of scenarios and life situations. We ensure each document is in adherence with the regulations of each state, so you don’t have to be concerned about potential legal pitfalls compliance-wise.

If you're already aware of our services and have a subscription with US, you know how effortless it is to get the Chicago Equipment Maintenance Agreement with a Manufacturer template. Go ahead and log in to your account, download the template, and personalize it to your needs. Have you lost your document? No worries. You can find it in the My Forms tab in your account - on desktop or mobile.

The onboarding flow of new users is fairly easy! Here’s what you need to do before downloading Chicago Equipment Maintenance Agreement with a Manufacturer:

- Make sure that your form is compliant with your state/county since the regulations for creating legal paperwork may vary from one state another.

- Find out more about the form by previewing it or going through a quick description. If the Chicago Equipment Maintenance Agreement with a Manufacturer isn’t something you were hoping to find, then take advantage of the search bar in the header to find another one.

- Log in or create an account to start utilizing our service and get the form.

- Everything looks good on your end? Click the Buy now button and select the subscription option.

- Pick the payment gateway and type in your payment information.

- Your template is ready to go. You can go ahead and download it.

It’s an easy task to find and buy the appropriate template with US Legal Forms. Thousands of organizations and individuals are already taking advantage of our extensive library. Subscribe to it now if you want to check what other benefits you can get with US Legal Forms!