San Jose California Equipment Maintenance Agreement with a Manufacturer: A Detailed Description Keywords: San Jose California, equipment maintenance agreement, manufacturer, types. Introduction: San Jose, California, is renowned for its thriving industry and advanced technological infrastructure. To ensure the seamless functioning of equipment and machinery, businesses in the region often enter into Equipment Maintenance Agreements (EMA) with manufacturers. These agreements establish a comprehensive framework for routine inspections, repairs, and servicing of equipment to enhance performance and minimize downtime. Let's explore the key aspects and types of Equipment Maintenance Agreements commonly found in San Jose, California. Description of Equipment Maintenance Agreement: An Equipment Maintenance Agreement is a legally binding contract between a business in San Jose, California, and a manufacturer. Typically, it outlines the terms and conditions under which the manufacturer will provide maintenance services for the equipment purchased by the business. These agreements are crucial for ensuring the longevity, reliability, and productivity of equipment, minimizing unexpected breakdowns, and guaranteeing a prompt response in case of equipment failure. Key Components of an Equipment Maintenance Agreement: 1. Scope of Services: The agreement explicitly defines the range of equipment covered under the maintenance services, including specific make, model, and serial numbers. It outlines the manufacturer's responsibilities in terms of inspections, routine maintenance, repairs, and replacement of parts and components. 2. Maintenance Schedule: The agreement establishes a maintenance schedule, dictating when routine inspections and servicing will occur. It ensures regular monitoring to detect potential issues before they escalate, thereby preventing costly breakdowns and production disruptions. 3. Response Time: The EMA defines the manufacturer's response time in case of equipment failures or emergencies. This provision helps businesses to estimate the potential downtime and align their operations accordingly. 4. Agreement Duration: The duration of the agreement, usually stated in months or years, is specified. It may include provisions for automatic renewal or termination upon certain conditions. 5. Maintenance Costs: The agreement outlines the cost of maintenance services, including service fees, labor charges, and costs arising from replacing faulty or worn-out parts. It may also detail additional expenses, such as transporting equipment to the manufacturer's facility for repairs. Types of Equipment Maintenance Agreements in San Jose, California: 1. Preventive Maintenance Agreement (PMA): This type of agreement focuses on proactive inspections and maintenance to prevent equipment failures and minimize downtime. Manufacturers conduct routine servicing, lubrication, calibration, and assessment of equipment health to identify potential issues before they cause disruptions. 2. Corrective Maintenance Agreement (CMA): CMA contracts ensure manufacturers respond promptly to unexpected equipment malfunctions, failures, or breakdowns. Repairs, part replacements, and troubleshooting are performed expediently to restore equipment functionality and minimize downtime. 3. Comprehensive Maintenance Agreement (CMA): A comprehensive agreement combines preventive and corrective maintenance services. It covers routine inspections, proactive maintenance, and immediate repairs in case of failures. This type of agreement provides businesses in San Jose, California, with complete peace of mind, as their equipment is meticulously cared for throughout its operation. Conclusion: San Jose, California, Equipment Maintenance Agreements are essential for ensuring the optimal performance and durability of various industrial equipment. Whether it be preventive, corrective, or comprehensive agreements, businesses in the region depend on these agreements to safeguard their investment and maintain consistently efficient operations. These agreements foster a mutually beneficial relationship between manufacturers and businesses, reinforcing San Jose's reputation as a center for innovation, technology, and reliable equipment maintenance.

San Jose California Equipment Maintenance Agreement with a Manufacturer

Description

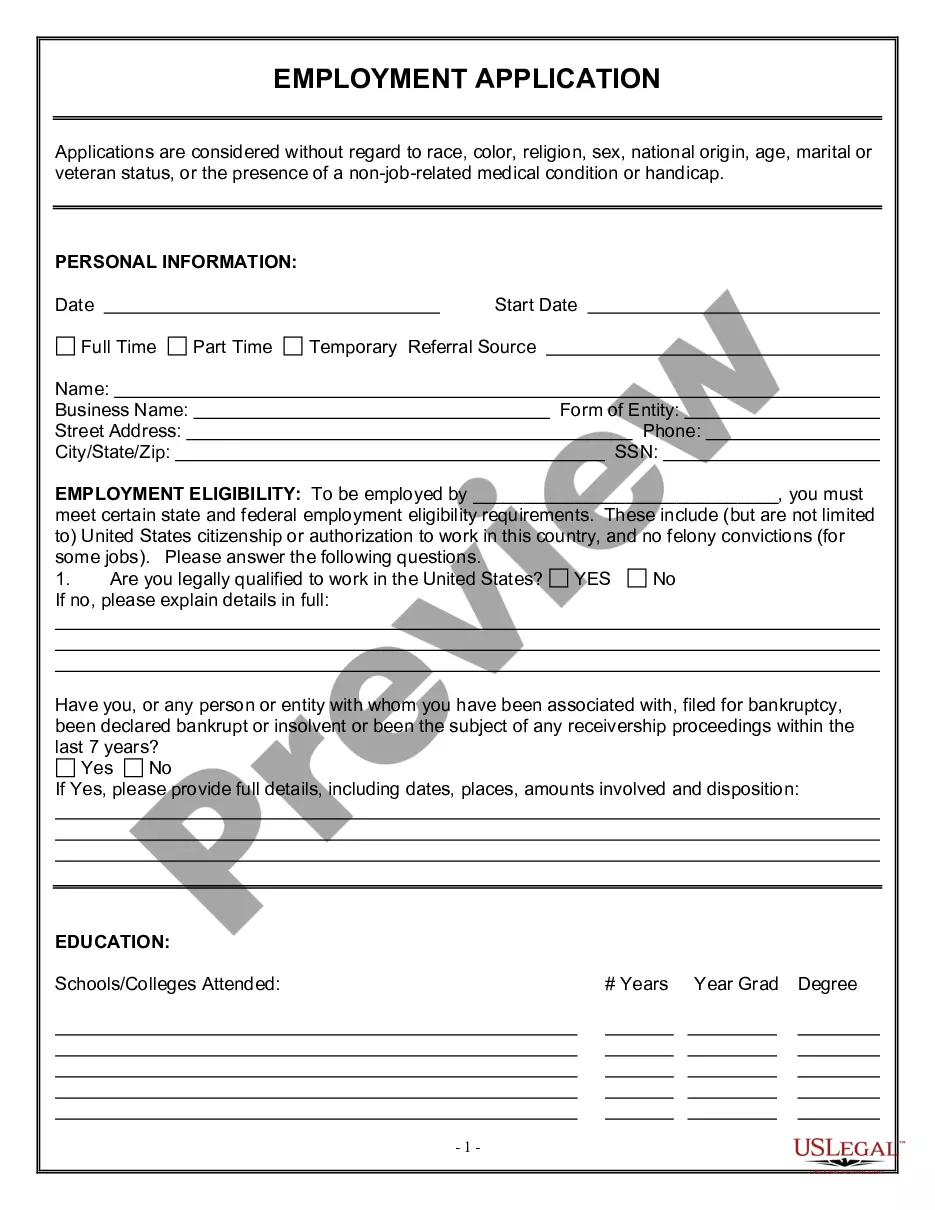

How to fill out San Jose California Equipment Maintenance Agreement With A Manufacturer?

How much time does it typically take you to draft a legal document? Because every state has its laws and regulations for every life situation, locating a San Jose Equipment Maintenance Agreement with a Manufacturer meeting all regional requirements can be tiring, and ordering it from a professional lawyer is often expensive. Numerous online services offer the most common state-specific templates for download, but using the US Legal Forms library is most beneficial.

US Legal Forms is the most extensive online collection of templates, collected by states and areas of use. In addition to the San Jose Equipment Maintenance Agreement with a Manufacturer, here you can get any specific document to run your business or individual affairs, complying with your regional requirements. Specialists check all samples for their validity, so you can be certain to prepare your documentation correctly.

Using the service is fairly simple. If you already have an account on the platform and your subscription is valid, you only need to log in, pick the required sample, and download it. You can pick the document in your profile at any moment later on. Otherwise, if you are new to the website, there will be a few more actions to complete before you obtain your San Jose Equipment Maintenance Agreement with a Manufacturer:

- Examine the content of the page you’re on.

- Read the description of the sample or Preview it (if available).

- Search for another document utilizing the related option in the header.

- Click Buy Now once you’re certain in the selected document.

- Select the subscription plan that suits you most.

- Register for an account on the platform or log in to proceed to payment options.

- Pay via PalPal or with your credit card.

- Change the file format if needed.

- Click Download to save the San Jose Equipment Maintenance Agreement with a Manufacturer.

- Print the sample or use any preferred online editor to complete it electronically.

No matter how many times you need to use the purchased template, you can locate all the samples you’ve ever downloaded in your profile by opening the My Forms tab. Give it a try!