Fairfax Virginia Inspection of Goods and Acceptance refers to the process of thoroughly examining and assessing the quality, quantity, and condition of goods received by individuals or businesses in Fairfax, Virginia. This inspection ensures that the goods meet specific standards, specifications, and requirements before being accepted and used or sold. Some relevant keywords associated with Fairfax Virginia Inspection of Goods and Acceptance include inspection, goods, acceptance, quality control, examination, standards, specifications, conditions, and Fairfax, Virginia. Different types of Fairfax Virginia Inspection of Goods and Acceptance may include: 1. Pre-Delivery Inspection (PDI): conducted before goods are delivered to check if they meet the required specifications, ensuring conformity and preventing defects or damages during transportation. 2. Reshipment Inspection (PSI): performed prior to shipment to verify the quality, quantity, and packing of goods, ensuring compliance with purchase orders and contracts. 3. In-Process Inspection: carried out during the manufacturing process to monitor and control the quality standards, identifying any defects or deviations, and enabling corrective actions before completion. 4. Receiving Inspection: performed upon receipt of goods to check for damages, verify order accuracy, and ensure delivered goods meet the agreed-upon specifications. 5. Final Inspection: conducted at the end of the manufacturing process to examine goods for any potential defects, verifying if they meet the predetermined quality standards. 6. Random Sampling Inspection: involves randomly selecting a sample size from goods for inspection, ensuring representative assessment without examining every single item. 7. Periodic Inspection: regular inspections conducted at predetermined intervals to ensure ongoing compliance with quality standards and to identify any potential deviations or issues. 8. Product Testing: specific inspection method involving performing various tests on goods to evaluate their performance, durability, safety, or functionality. 9. Vendor Inspection: inspection activities carried out by third-party inspectors or customer representatives at the vendor's facility, ensuring the goods meet the buyer's requirements and standards. Fairfax Virginia Inspection of Goods and Acceptance plays a vital role in maintaining product quality, reducing risks, and ensuring customer satisfaction by assuring that goods meet the desired standards and specifications.

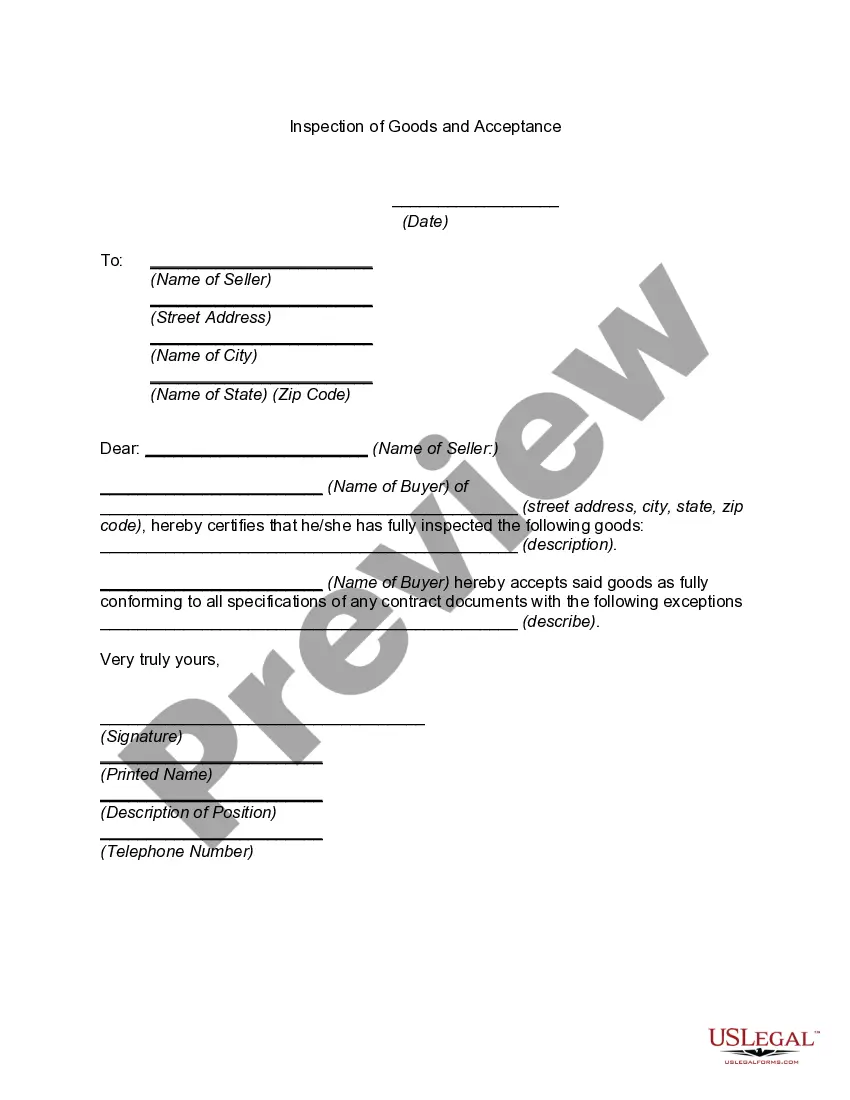

Fairfax Virginia Inspection of Goods and Acceptance

Description

How to fill out Fairfax Virginia Inspection Of Goods And Acceptance?

If you need to get a trustworthy legal form supplier to obtain the Fairfax Inspection of Goods and Acceptance, look no further than US Legal Forms. Whether you need to launch your LLC business or manage your belongings distribution, we got you covered. You don't need to be knowledgeable about in law to find and download the needed template.

- You can browse from more than 85,000 forms arranged by state/county and situation.

- The self-explanatory interface, number of learning materials, and dedicated support team make it simple to locate and complete various documents.

- US Legal Forms is a reliable service providing legal forms to millions of customers since 1997.

Simply select to search or browse Fairfax Inspection of Goods and Acceptance, either by a keyword or by the state/county the document is created for. After locating necessary template, you can log in and download it or retain it in the My Forms tab.

Don't have an account? It's simple to start! Simply find the Fairfax Inspection of Goods and Acceptance template and take a look at the form's preview and description (if available). If you're comfortable with the template’s language, go ahead and hit Buy now. Register an account and choose a subscription option. The template will be instantly ready for download as soon as the payment is completed. Now you can complete the form.

Handling your law-related matters doesn’t have to be expensive or time-consuming. US Legal Forms is here to prove it. Our extensive collection of legal forms makes these tasks less pricey and more reasonably priced. Create your first company, arrange your advance care planning, draft a real estate agreement, or complete the Fairfax Inspection of Goods and Acceptance - all from the comfort of your home.

Sign up for US Legal Forms now!