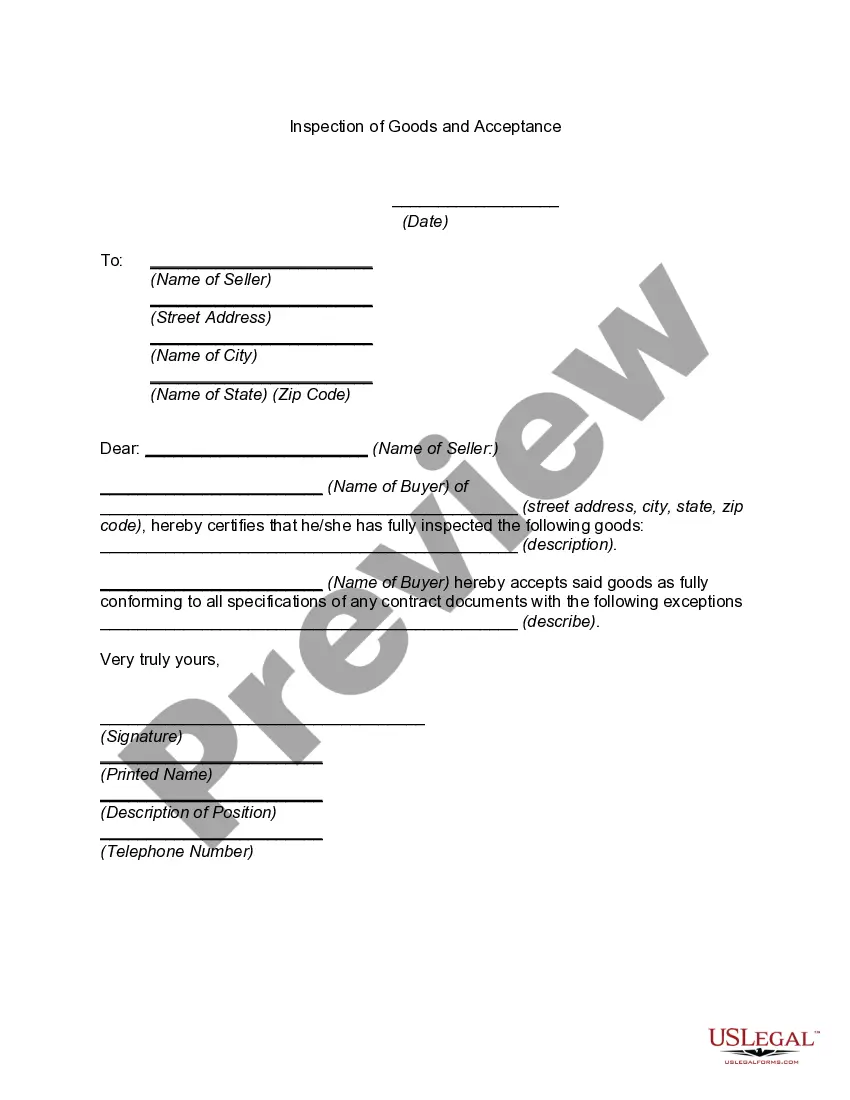

Lima Arizona Inspection of Goods and Acceptance is a crucial step in the procurement and supply chain management processes. It involves thorough evaluation and assessment of goods to ensure compliance with specified requirements and contractual obligations. This inspection serves as a protection mechanism for both buyers and suppliers, as it helps prevent potential disputes and ensures the delivery of high-quality goods. The Lima Arizona Inspection of Goods and Acceptance encompasses meticulous examination of various aspects of the delivered products, such as dimensions, quantities, quality, packaging, labeling, and overall condition. It aims to verify if the received goods meet all predetermined specifications, standards, and expectations. This inspection process may be conducted by internal quality control teams or by specialized third-party inspection agencies, depending on the nature of the contract and its terms. In Lima Arizona, there are different types of Inspection of Goods and Acceptance, each serving a specific purpose: 1. Reshipment Inspection: This type of inspection takes place before the goods are shipped from the supplier's location. It ensures that the products are in line with the buyer's requirements and conform to all applicable industry standards. Pre-shipment inspections prevent the transportation of defective or substandard goods, reducing the chances of disputes or rejections upon arrival. 2. Receiving Inspection: This inspection occurs upon the receipt of goods at the buyer's facility. It involves a comprehensive review of the delivered items to ensure they match the order specifications, including quantity, quality, and condition. Receiving inspections aid in detecting any discrepancies or damages that might have occurred during transit, allowing for timely resolution or necessary claims. 3. In-Process Inspection: This type of inspection takes place during the manufacturing or production stage. It involves periodic checks and evaluations to ensure goods are being manufactured according to defined standards and specifications. In-process inspections help identify potential defects or deviations early on, facilitating immediate corrective actions and preventing the production of many defective goods. 4. Final Inspection: The final inspection occurs when the goods are ready for delivery to the buyer. It is a comprehensive assessment to confirm that all required specifications have been met, ensuring the overall quality and conformity of the products. This inspection is essential to mitigate any last-minute issues and guarantee that the goods are in optimal condition before the handover. By conducting the Lima Arizona Inspection of Goods and Acceptance, buyers can ascertain the quality and compliance of the received goods, while suppliers can ensure customer satisfaction and adherence to contractual obligations. This process minimizes the risk of disputes, rejections, and financial losses, ultimately fostering a reliable and efficient supply chain ecosystem.

Pima Arizona Inspection of Goods and Acceptance

Description

How to fill out Pima Arizona Inspection Of Goods And Acceptance?

Whether you plan to open your company, enter into a deal, apply for your ID update, or resolve family-related legal concerns, you must prepare certain documentation corresponding to your local laws and regulations. Locating the correct papers may take a lot of time and effort unless you use the US Legal Forms library.

The platform provides users with more than 85,000 expertly drafted and verified legal documents for any personal or business case. All files are collected by state and area of use, so picking a copy like Pima Inspection of Goods and Acceptance is quick and easy.

The US Legal Forms library users only need to log in to their account and click the Download button next to the required template. If you are new to the service, it will take you several additional steps to obtain the Pima Inspection of Goods and Acceptance. Follow the instructions below:

- Make certain the sample meets your individual needs and state law requirements.

- Look through the form description and check the Preview if available on the page.

- Utilize the search tab specifying your state above to find another template.

- Click Buy Now to obtain the sample once you find the correct one.

- Select the subscription plan that suits you most to proceed.

- Sign in to your account and pay the service with a credit card or PayPal.

- Download the Pima Inspection of Goods and Acceptance in the file format you require.

- Print the copy or complete it and sign it electronically via an online editor to save time.

Documents provided by our library are reusable. Having an active subscription, you are able to access all of your previously purchased paperwork whenever you need in the My Forms tab of your profile. Stop wasting time on a endless search for up-to-date formal documents. Sign up for the US Legal Forms platform and keep your paperwork in order with the most extensive online form library!