San Antonio Texas Inspection of Goods and Acceptance

Description

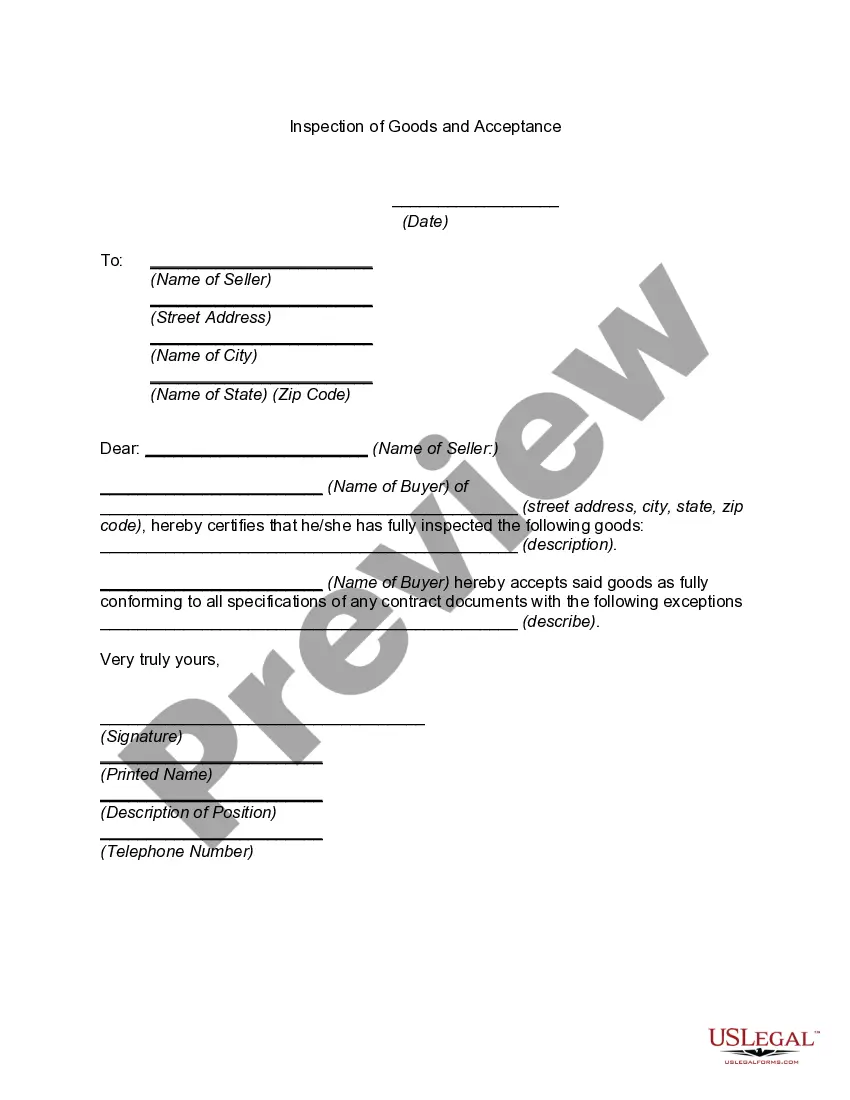

How to fill out Inspection Of Goods And Acceptance?

Whether you plan to launch your enterprise, enter into an agreement, apply for an identification update, or address family-related legal issues, you must gather specific documentation that complies with your local laws and regulations.

Locating the appropriate documents can require substantial time and effort unless you utilize the US Legal Forms library.

The platform offers users over 85,000 professionally crafted and verified legal templates for any personal or business situation. All files are organized by state and area of usage, making it quick and easy to select a document such as San Antonio Inspection of Goods and Acceptance.

Documents offered by our library are reusable. With an active subscription, you can access all of your previously purchased paperwork at any time in the My documents section of your profile. Eliminate time wasted on an endless search for current official documents. Join the US Legal Forms platform and maintain your paperwork organized with the most extensive online form library!

- Ensure the sample fulfills your personal requirements and state law stipulations.

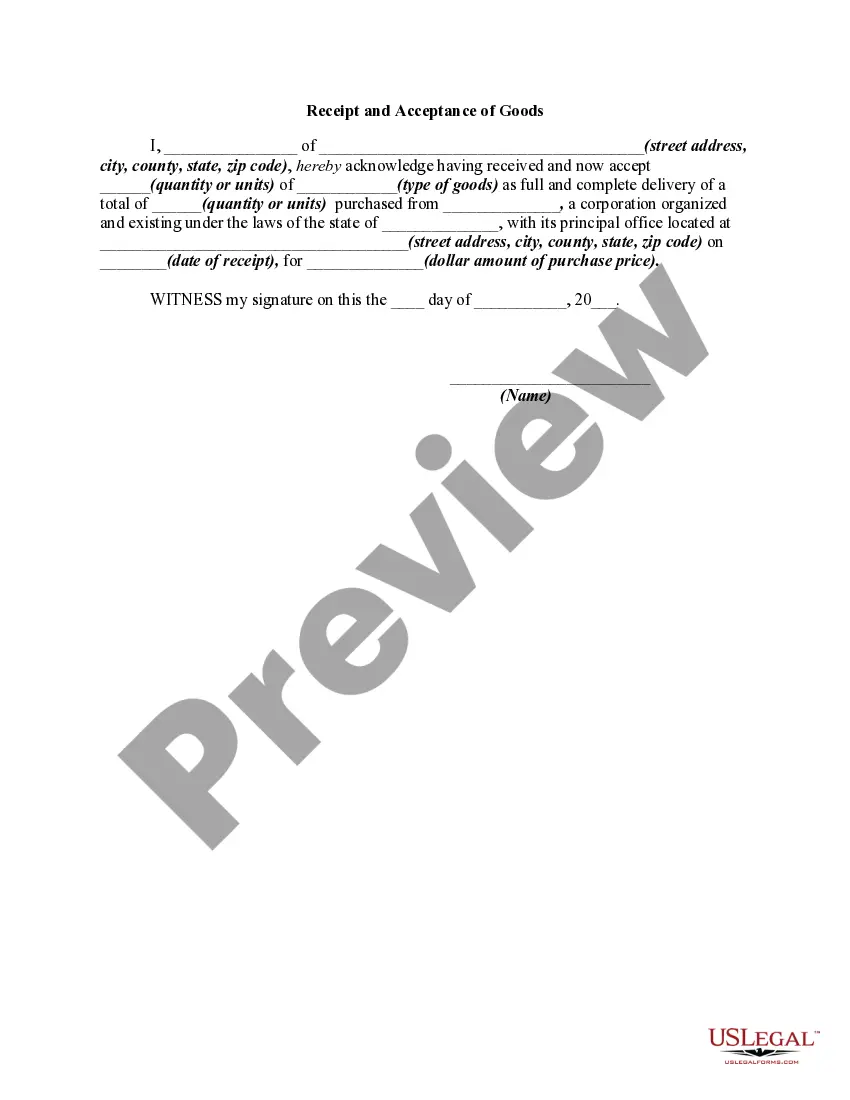

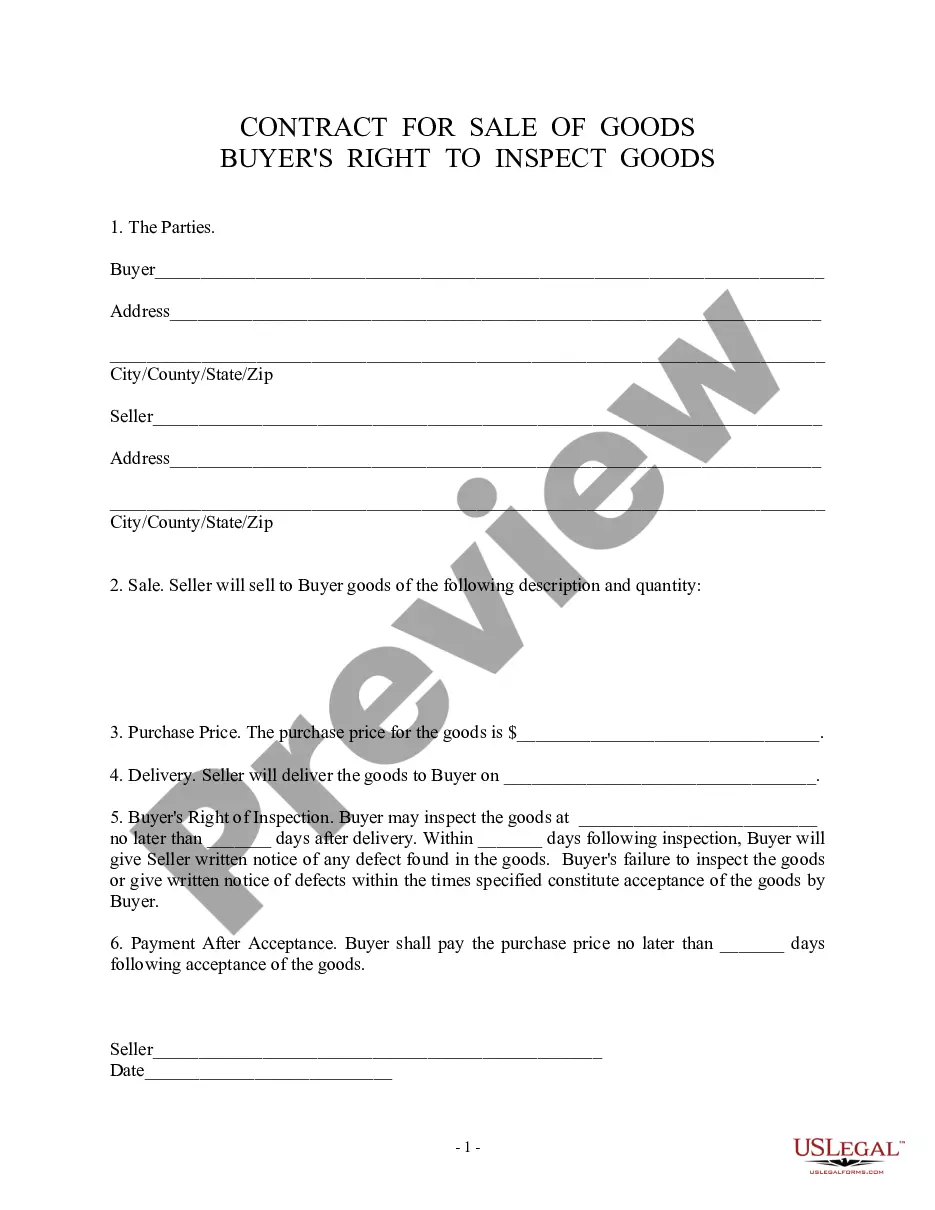

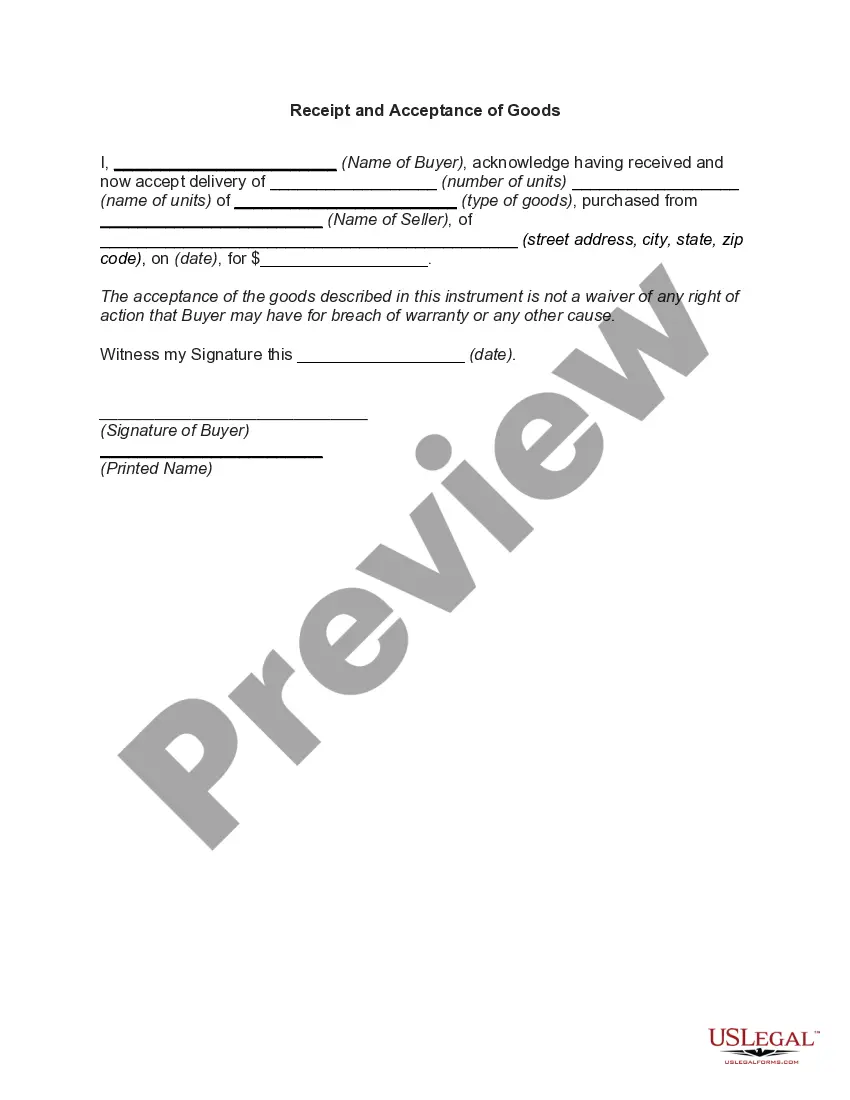

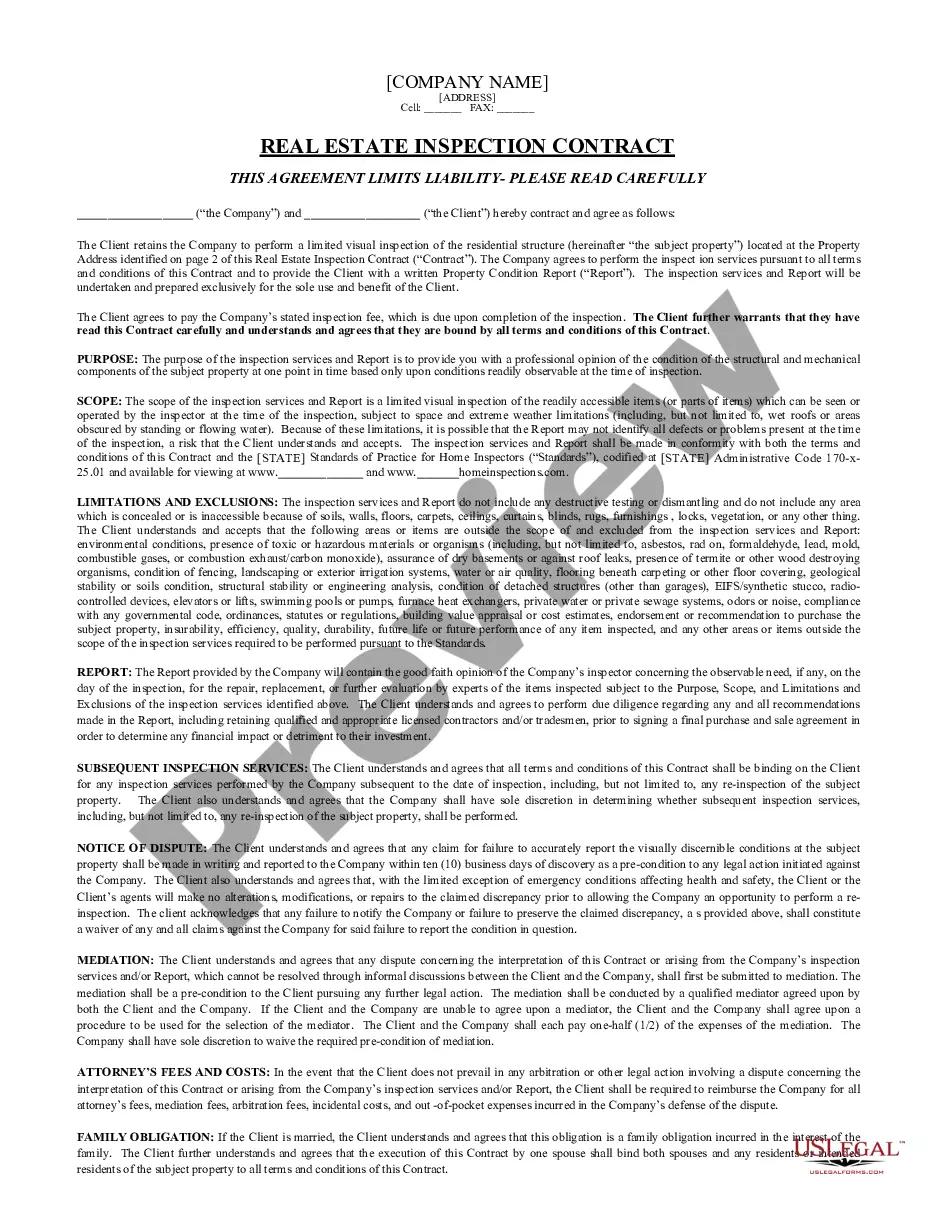

- Examine the form description and review the Preview if available on the page.

- Use the search bar specifying your state above to locate another template.

- Click Buy Now to acquire the file when you identify the appropriate one.

- Select the subscription plan that best fits your needs to proceed.

- Log in to your account and pay the service using a credit card or PayPal.

- Download the San Antonio Inspection of Goods and Acceptance in your desired file format.

- Print the document or complete it and sign it electronically through an online editor to save time.

Form popularity

FAQ

Texas is revising its vehicle inspection program to improve efficiency and reduce costs for residents. The changes aim to streamline the San Antonio Texas Inspection of Goods and Acceptance process, making it more accessible for vehicle owners. Despite potential changes, key safety inspections will still focus on critical components to maintain public safety. Staying informed about the ongoing adjustments will help you navigate the requirements effectively.

To get a Texas vehicle inspection, visit a licensed inspection station in your area. In San Antonio, Texas, the inspection of goods and acceptance includes checking essential vehicle components to ensure safety and compliance. You will need to bring your vehicle registration and provide proof of insurance. Upon successful completion of the inspection, you will receive a certificate that you can use for vehicle registration.

RDPiRC stands for the Regional Department of Public Inspection and Regulatory Compliance. This organization plays a crucial role in ensuring that the San Antonio Texas Inspection of Goods and Acceptance processes meet all local regulations. They support businesses and individuals by providing guidance on compliance matters. If you need help navigating the inspection process, RDPiRC can be a valuable resource for clarifying your questions.

The primary phone number for the city of San Antonio is 210-207-6000. By calling this number, you can connect with various city departments for information and assistance related to services like the San Antonio Texas Inspection of Goods and Acceptance. It’s important to have your questions ready, so you can get the help you need promptly. Additionally, city representatives can guide you through any necessary procedures or services.

To report a problem to the city of San Antonio, you can use the city's official website or mobile app. These platforms enable residents to address issues such as garbage collection, street maintenance, and more efficiently. For matters related to the San Antonio Texas Inspection of Goods and Acceptance, ensure you provide specific details for a quicker response. You can also contact the 311 service for immediate assistance.

A certificate of occupancy in San Antonio generally costs around $50 to $150, depending on the specific permit requirements. This document confirms that your premises comply with local building codes, which is vital when engaging in activities under the San Antonio Texas Inspection of Goods and Acceptance. Ensure you review your application's details for any additional fees that may apply.

If you observe a code violation in San Antonio, you can report it through the city’s Code Compliance Division. This can typically be done online through their portal, ensuring a smoother process. Reporting these violations helps maintain the integrity of San Antonio's standards, including those related to the San Antonio Texas Inspection of Goods and Acceptance.

Scheduling an inspection in San Antonio involves identifying the type of inspection you need. You can visit the San Antonio city website or contact the relevant department for guidance. Make sure to have any necessary documentation ready, particularly if your inspection relates to the San Antonio Texas Inspection of Goods and Acceptance.

To schedule a home inspection, start by researching local inspectors with good reviews. You can contact them directly to inquire about availability and services related to the San Antonio Texas Inspection of Goods and Acceptance. Many inspectors offer online booking, making it convenient to secure your appointment at your preferred time.

In San Antonio, you typically need a business license to operate legally. This requirement helps ensure that businesses meet specific standards while engaging in activities like San Antonio Texas Inspection of Goods and Acceptance. You can check with the city’s Small Business Office for detailed licensing requirements tailored to your business type.