San Jose, California Inspection of Goods and Acceptance: A Detailed Description In San Jose, California, inspection of goods and acceptance plays a crucial role in various industries, ensuring the quality, compliance, and adherence to standards of the received goods. It encompasses a systematic evaluation process wherein various factors such as functionality, safety, accuracy, and condition of the goods are inspected to determine their suitability for use or sale. This process is often conducted by certified professionals equipped with the necessary expertise to guarantee the quality and reliability of the inspected goods. Key aspects of the inspection process may include: 1. Pre-instruction Planning: This phase involves setting inspection objectives, establishing guidelines, and determining the specific requirements and parameters to be assessed. It may involve communication with suppliers, obtaining necessary documentation, and scheduling inspections. 2. Physical Inspection: Once the goods arrive, a physical examination is performed, encompassing visual checks, measurements, and sampling, if applicable. This step ensures that the goods meet the specified dimensions, appearance, and overall condition agreed upon during the procurement process. 3. Quality Assessment: During this stage, quality measures are examined against predetermined standards. This includes verifying the functionality, performance, and durability of the goods to ensure they meet the desired quality benchmarks. 4. Safety Evaluation: Inspection professionals also focus on assessing the safety attributes of the goods, especially in industries where the products may pose potential risks. Compliance with safety regulations and guidelines is thoroughly examined to ensure the protection of end-users and the public. 5. Documentation Review: Inspection of goods involves reviewing important documentation such as invoices, certificates of conformity, product manuals, and warranties. This guarantees that the delivered goods align with the agreed terms, specifications, and legal requirements. 6. Acceptance or Rejection: Based on the inspection results, a decision is made regarding the acceptance or rejection of the goods. If the goods meet all the required standards, they are accepted, allowing for further processing, distribution, or usage. In case the inspection reveals discrepancies or failures, the goods are rejected, triggering further actions such as return, replacement, or dispute resolution. Different Types of Inspection of Goods and Acceptance in San Jose, California: 1. Incoming Goods Inspection: This type of inspection focuses on examining and verifying the quality and condition of goods upon their arrival at a receiving facility. It ensures that the received items match the order specifications and meet the required quality standards. 2. Production Line Inspection: Conducted during the manufacturing process, this inspection aims to evaluate the goods' adherence to quality standards and identify potential defects or issues before reaching the final stages. It helps in minimizing waste, optimizing production, and ensuring consistent quality. 3. Final Product Inspection: Once the goods are completely manufactured, a comprehensive inspection is performed to verify if the final product meets the predefined quality criteria. This inspection is crucial for ensuring customer satisfaction and minimizing the risk of faulty or substandard products in the marketplace. In summary, San Jose, California's inspection of goods and acceptance is a meticulous process that safeguards the quality and compliance of received goods. From pre-instruction planning to final acceptance or rejection, the inspection professionals thoroughly assess various factors to ensure that the goods meet the necessary standards. Different types of inspections such as incoming goods' inspection, production line inspection, and final product inspection serve distinct purposes in maintaining quality control throughout the supply chain.

San Jose California Inspection of Goods and Acceptance

Description

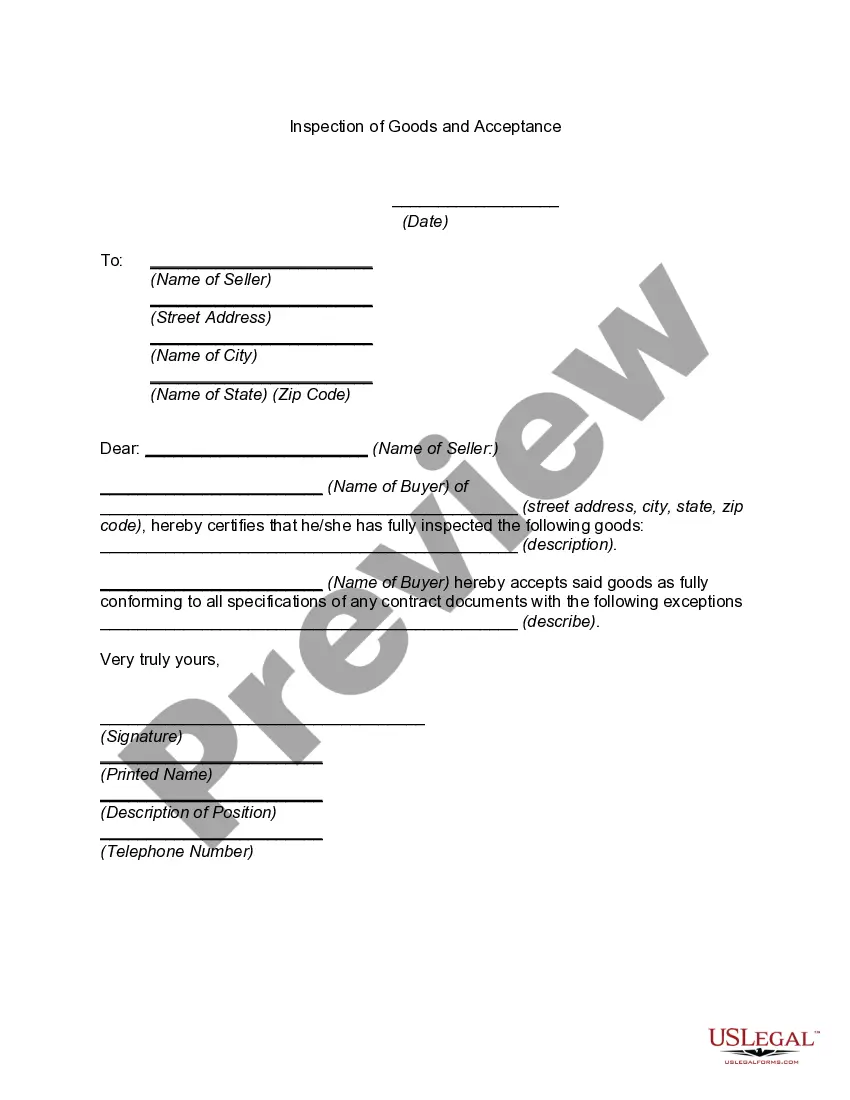

How to fill out San Jose California Inspection Of Goods And Acceptance?

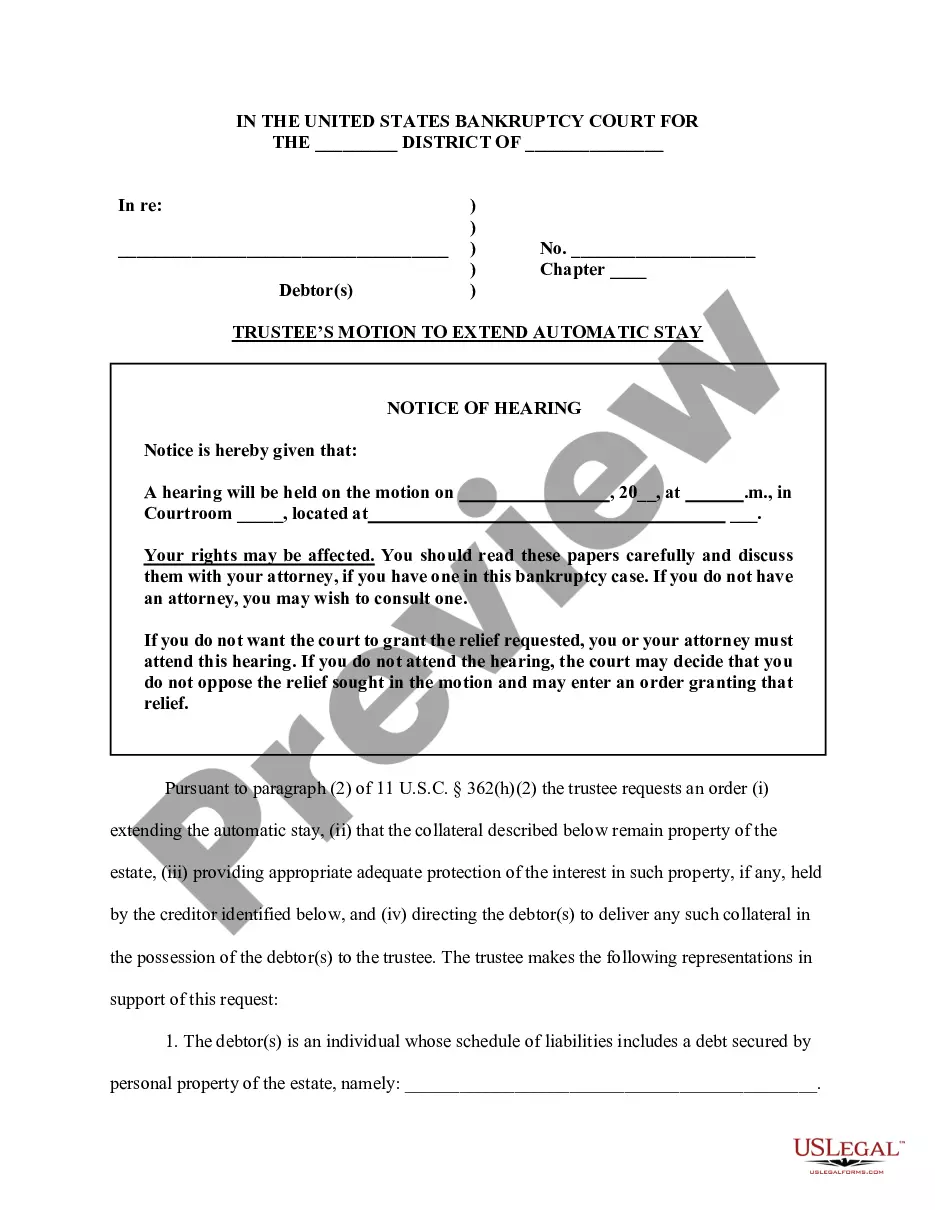

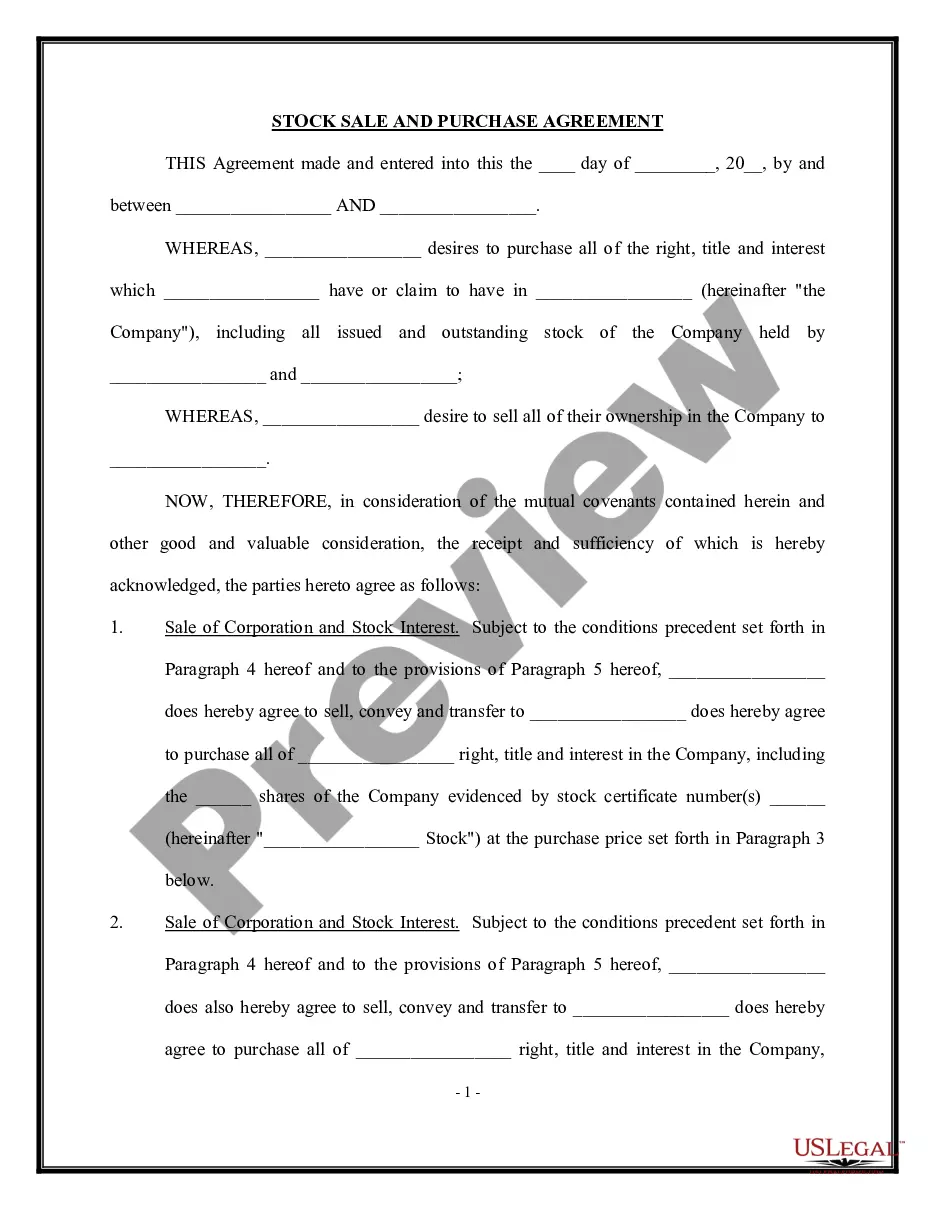

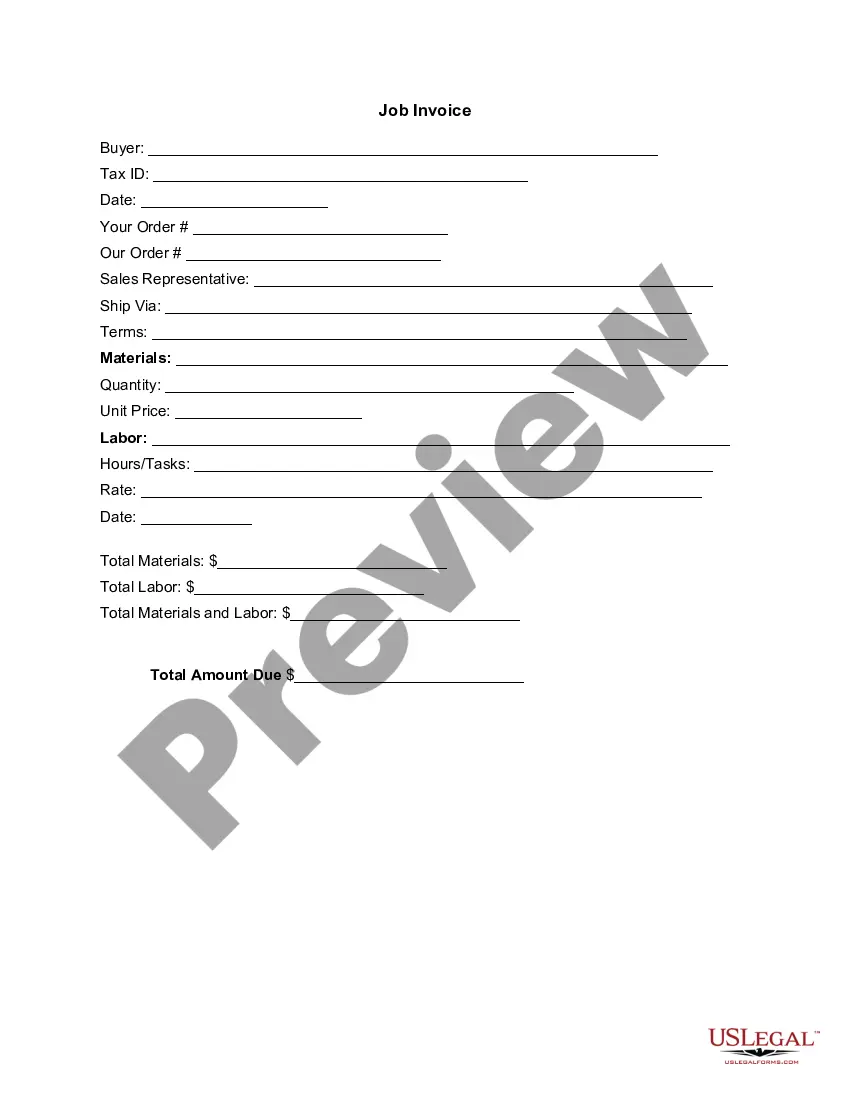

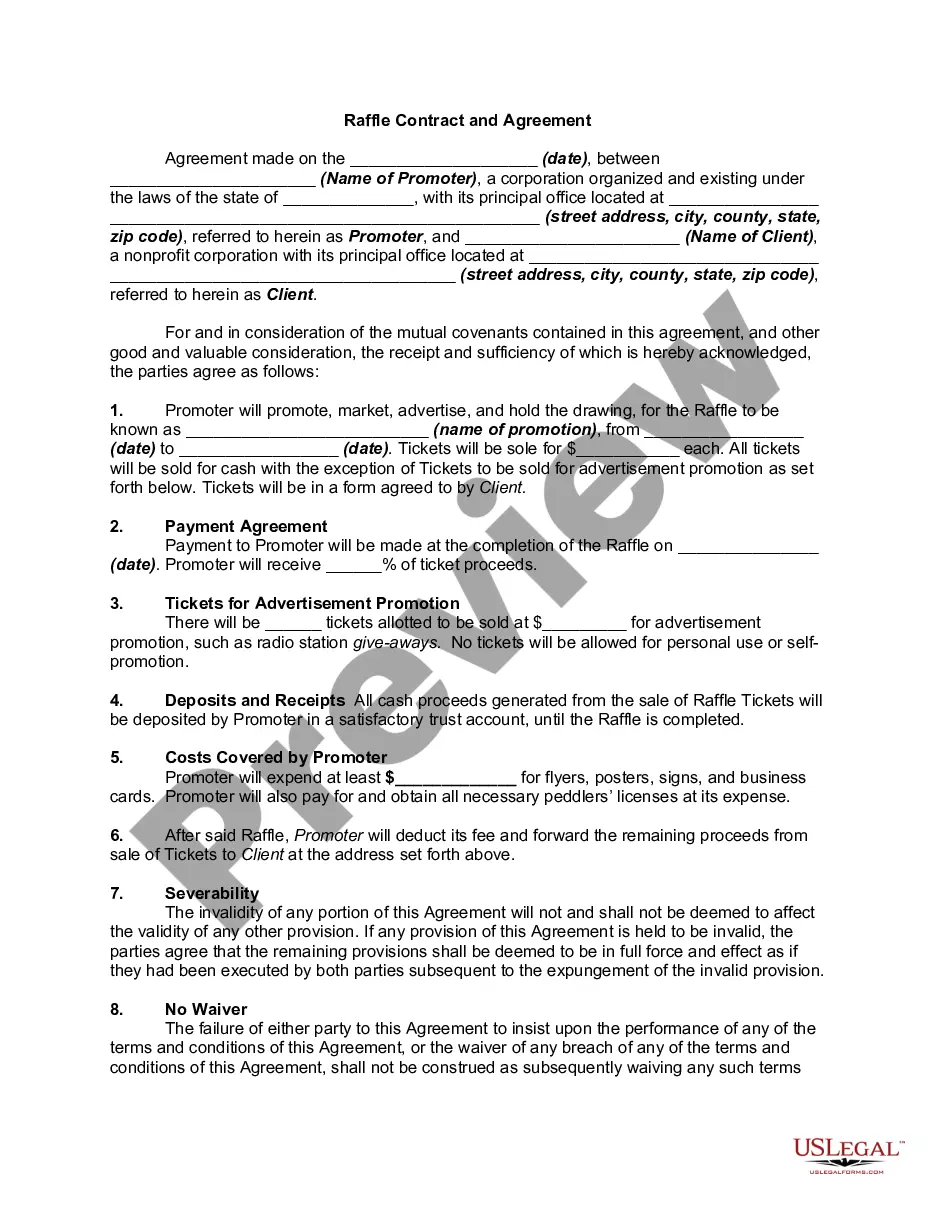

Preparing legal paperwork can be difficult. In addition, if you decide to ask a legal professional to draft a commercial contract, papers for proprietorship transfer, pre-marital agreement, divorce papers, or the San Jose Inspection of Goods and Acceptance, it may cost you a lot of money. So what is the best way to save time and money and draw up legitimate documents in total compliance with your state and local regulations? US Legal Forms is a perfect solution, whether you're looking for templates for your individual or business needs.

US Legal Forms is biggest online collection of state-specific legal documents, providing users with the up-to-date and professionally checked templates for any use case collected all in one place. Therefore, if you need the recent version of the San Jose Inspection of Goods and Acceptance, you can easily find it on our platform. Obtaining the papers requires a minimum of time. Those who already have an account should check their subscription to be valid, log in, and select the sample using the Download button. If you haven't subscribed yet, here's how you can get the San Jose Inspection of Goods and Acceptance:

- Look through the page and verify there is a sample for your area.

- Examine the form description and use the Preview option, if available, to ensure it's the sample you need.

- Don't worry if the form doesn't suit your requirements - look for the correct one in the header.

- Click Buy Now once you find the needed sample and choose the best suitable subscription.

- Log in or sign up for an account to pay for your subscription.

- Make a transaction with a credit card or via PayPal.

- Opt for the file format for your San Jose Inspection of Goods and Acceptance and save it.

Once done, you can print it out and complete it on paper or upload the template to an online editor for a faster and more convenient fill-out. US Legal Forms enables you to use all the paperwork ever acquired multiple times - you can find your templates in the My Forms tab in your profile. Try it out now!