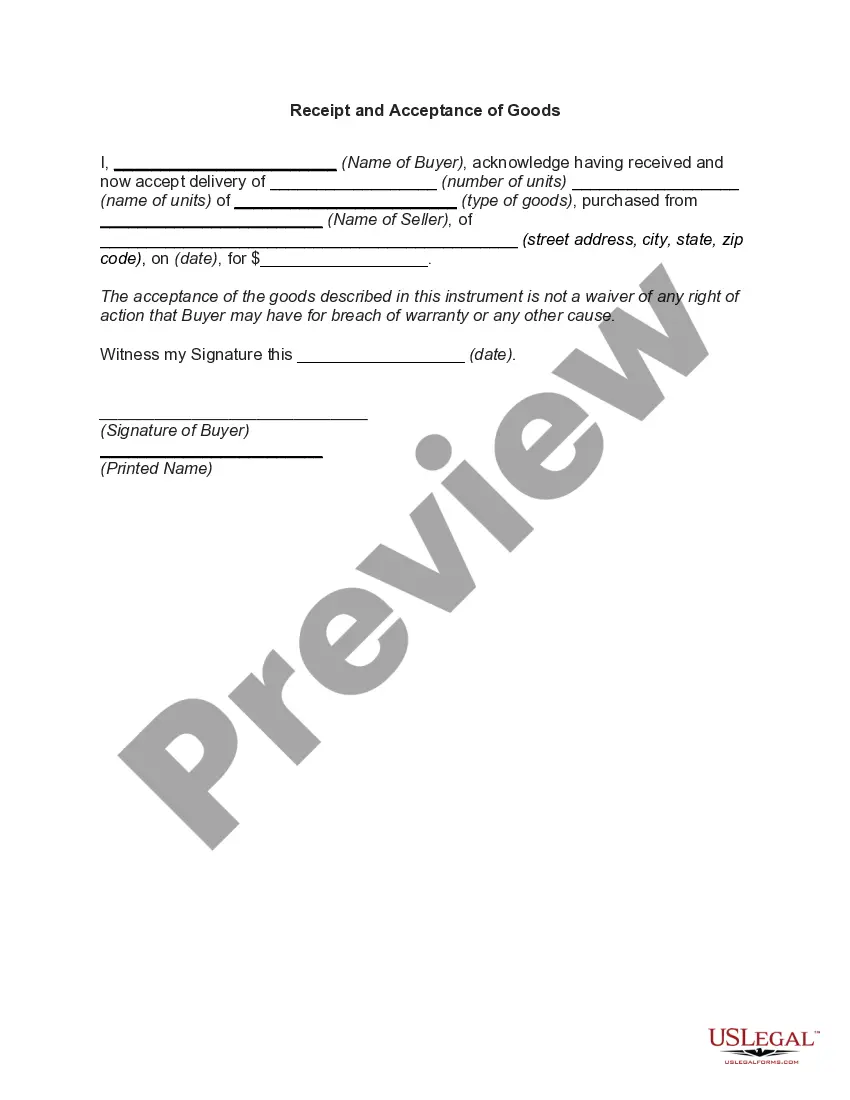

Cook Illinois Receipt and Acceptance of Goods is a crucial process involved in the supply chain management of Cook Illinois Corporation. It refers to the formal confirmation and documentation of the delivery and acceptance of goods by Cook Illinois from its suppliers or vendors. This process ensures that the goods received meet the specified quality and quantity requirements as defined in the purchase order. Keywords: Cook Illinois, receipt and acceptance of goods, supply chain management, delivery, suppliers, vendors, documentation, quality, quantity, purchase order. There are several types of Cook Illinois Receipt and Acceptance of Goods, which include: 1. Initial Receipt and Acceptance of Goods: This type involves the first inspection and documentation of the goods upon their arrival at Cook Illinois's facility. It includes checking the quantity of goods delivered, verifying the packaging integrity, and examining the overall condition of the goods to ensure they meet the specified quality standards. 2. Partial Receipt and Acceptance of Goods: In situations where the complete order is not delivered at once, Cook Illinois may accept a partial delivery. This type of receipt and acceptance involves confirming the quantity of goods received accurately, updating the inventory records accordingly, and initiating any necessary action to procure the remaining items. 3. Final Receipt and Acceptance of Goods: When all the goods listed in a purchase order have been delivered, Cook Illinois completes the final receipt and acceptance process. It involves conducting a thorough inspection to ensure that all goods meet the required quality standards. Any discrepancies or damages are documented and reported to the supplier for resolution. 4. Inspection-Based Acceptance: In certain cases, Cook Illinois may require detailed inspection and testing of the goods before accepting them. This can occur when the goods are highly specialized, complex, or subject to stringent quality control measures. The inspection-based acceptance involves verifying the goods against predetermined criteria, industry standards, or specifications. 5. Acceptance with Deviations: Occasionally, Cook Illinois may accept goods with minor deviations from the specified requirements, especially if the deviations do not significantly affect their usability or quality. In such cases, the receipt and acceptance process involves documenting the deviations, communicating with the supplier regarding the discrepancies, and seeking appropriate resolutions or compensation. In conclusion, Cook Illinois Receipt and Acceptance of Goods is a meticulous process encompassing various types depending on the specific situation. It ensures that the purchased goods conform to the prescribed quality and quantity standards, thereby upholding the company's commitment to delivering reliable and high-quality products to its customers.

Cook Illinois Receipt and Acceptance of Goods

Description

How to fill out Cook Illinois Receipt And Acceptance Of Goods?

Draftwing documents, like Cook Receipt and Acceptance of Goods, to take care of your legal matters is a challenging and time-consumming task. A lot of situations require an attorney’s participation, which also makes this task not really affordable. Nevertheless, you can acquire your legal issues into your own hands and handle them yourself. US Legal Forms is here to the rescue. Our website comes with over 85,000 legal documents crafted for various scenarios and life situations. We make sure each form is in adherence with the laws of each state, so you don’t have to be concerned about potential legal problems compliance-wise.

If you're already aware of our services and have a subscription with US, you know how straightforward it is to get the Cook Receipt and Acceptance of Goods template. Simply log in to your account, download the form, and personalize it to your requirements. Have you lost your form? No worries. You can get it in the My Forms tab in your account - on desktop or mobile.

The onboarding flow of new users is just as easy! Here’s what you need to do before downloading Cook Receipt and Acceptance of Goods:

- Ensure that your document is specific to your state/county since the regulations for creating legal paperwork may vary from one state another.

- Discover more information about the form by previewing it or going through a quick intro. If the Cook Receipt and Acceptance of Goods isn’t something you were looking for, then take advantage of the search bar in the header to find another one.

- Log in or create an account to start using our service and get the document.

- Everything looks good on your side? Hit the Buy now button and select the subscription option.

- Select the payment gateway and enter your payment information.

- Your template is all set. You can try and download it.

It’s easy to locate and buy the needed document with US Legal Forms. Thousands of organizations and individuals are already benefiting from our extensive collection. Sign up for it now if you want to check what other advantages you can get with US Legal Forms!

Form popularity

FAQ

The conformity of goods is determined not only by their quantity, quality, description, or packaging, but also by compliance with standards affecting the use of the goods, such as public law regulations and industry codes. 2. The relevant standards are those at the time of the conclusion of the contract.

Delivery and Acceptance means the process by which Goods and/or Services are delivered to a Customer and accepted by the Customer as meeting the terms specified in the Contract.

Acceptance means the receipt and retention of products delivered or services rendered by a Supplier following inspection to ensure conformance with contract specifications. Acceptance may take place before delivery, at delivery, or after delivery, depending on the contract's provisions.

According to the UCC, acceptance occurs when the buyer: after a reasonable opportunity to inspect the goods indicates to the seller that the goods are conforming or that he or she will take them in spite of any non-conformity.

Definition. Assent to the terms of an offer. Acceptance must be judged objectively, but can either be expressly stated or implied by the offeree's conduct. To form a binding contract, acceptance should be relayed in a manner authorized, requested, or at least reasonably expected by the offeror.

It is the right of the buyer to reject the goods if it is found that the seller has delivered him the goods of other quantity or quality or if the buyer notices any defects in the goods he may also refuse to take those defective goods.

(1) Acceptance of goods occurs when the buyer (a) after a reasonable opportunity to inspect the goods signifies to the seller that the goods are conforming or that he will take or retain them in spite of their nonconformity; or (b) fails to make an effective rejection as provided by subsection (1) of section 42a-2-602,

Delivery is the surrender of possession to another; the handing over of an object, document, or money. Delivery may be actual, symbolic, or constructive. Actual delivery means that the item is physically transferred from one party to another.

An acceptance is a contractual agreement by an importer to pay the amount due for receiving goods at a specified date in the future. Documents are presented for acceptance in international trade. The buyer of the goods or importer agrees to pay the draft and writes "accepted," or similar wording indicating acceptance.

Express acceptance occurs when an individual clearly and explicitly expresses his agreement to an offer. Examples of express acceptance include signing a contract, orally accepting the offer, shaking hands, or even exchanging business cards with the offer and accepted terms.

Interesting Questions

More info

We have a few ways to keep your pantry stocked: the. We have a few ways to keep your pantry stocked: the. For more information on these topics, please click the related links below.

Disclaimer

The materials in this section are taken from public sources. We disclaim all representations or any warranties, express or implied, as to the accuracy, authenticity, reliability, accessibility, adequacy, or completeness of any data in this paragraph. Nevertheless, we make every effort to cite public sources deemed reliable and trustworthy.