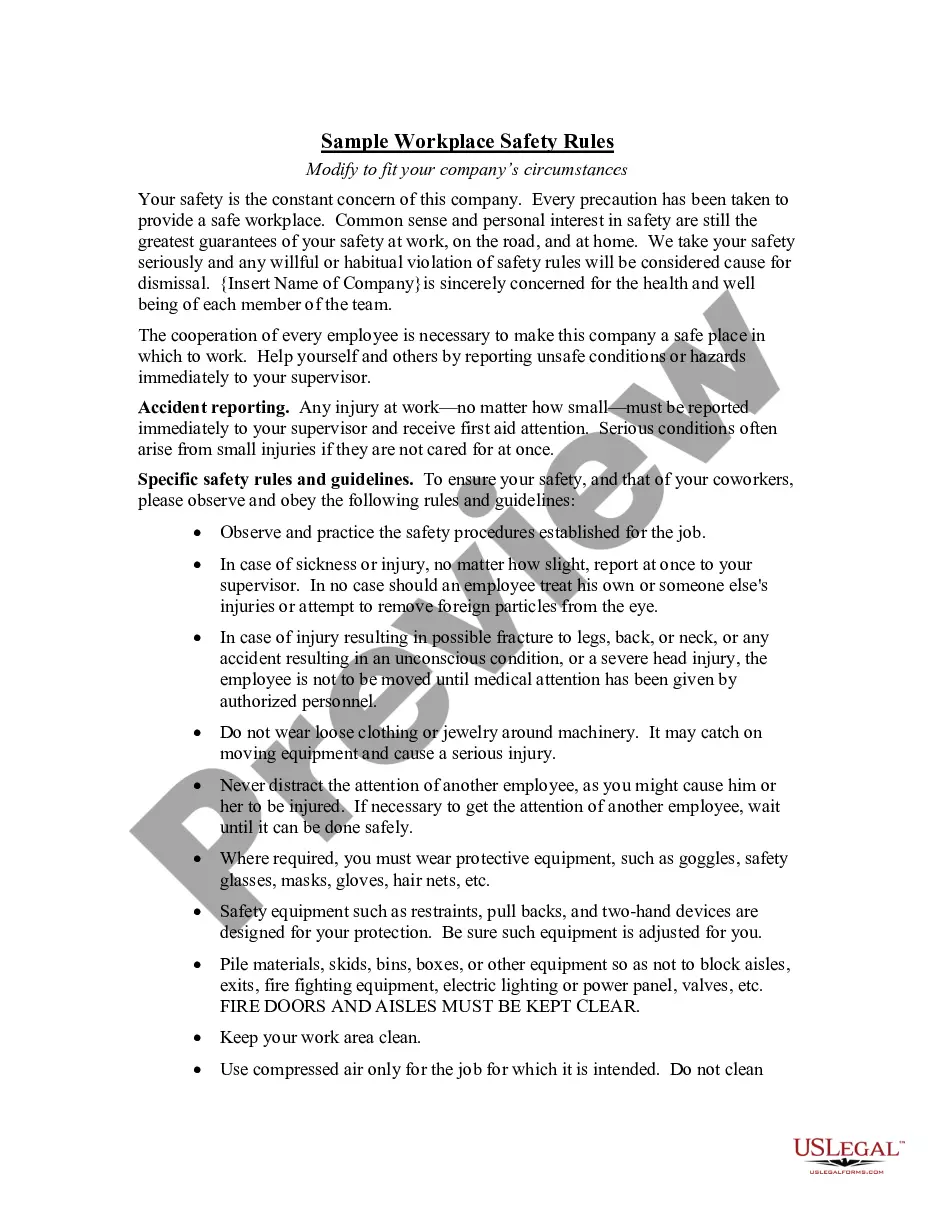

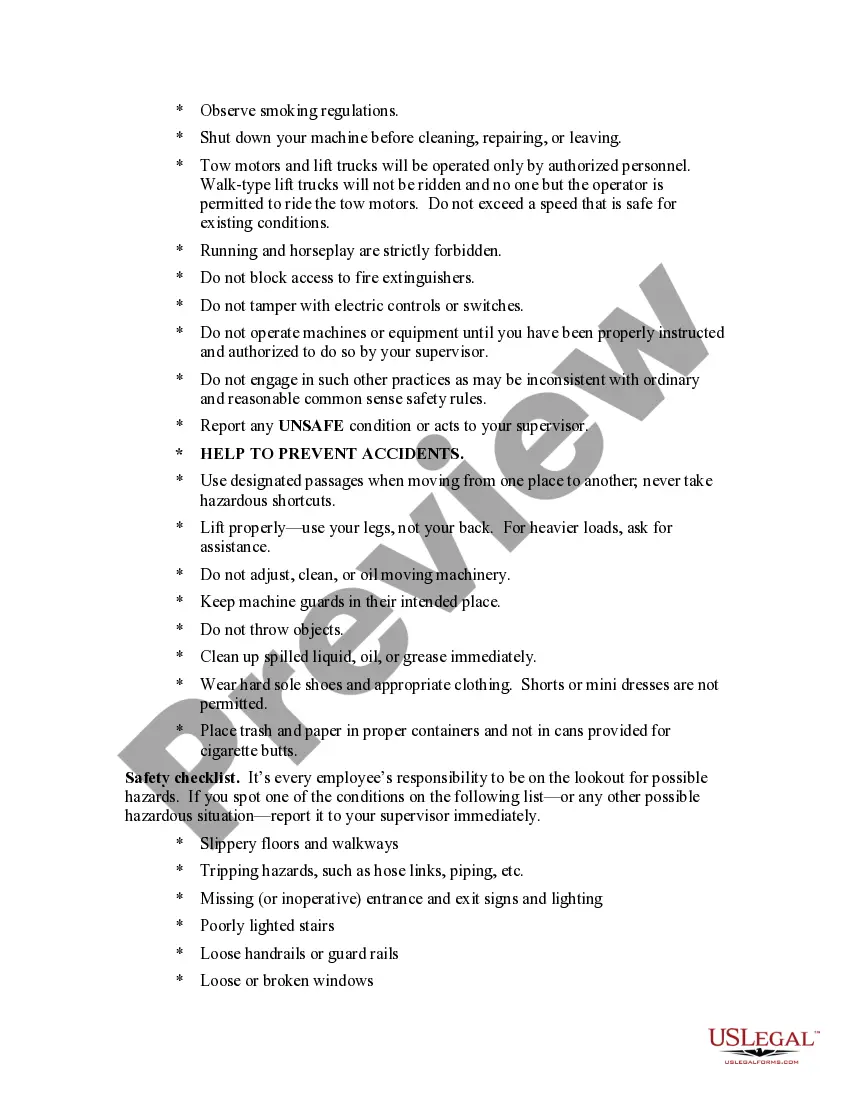

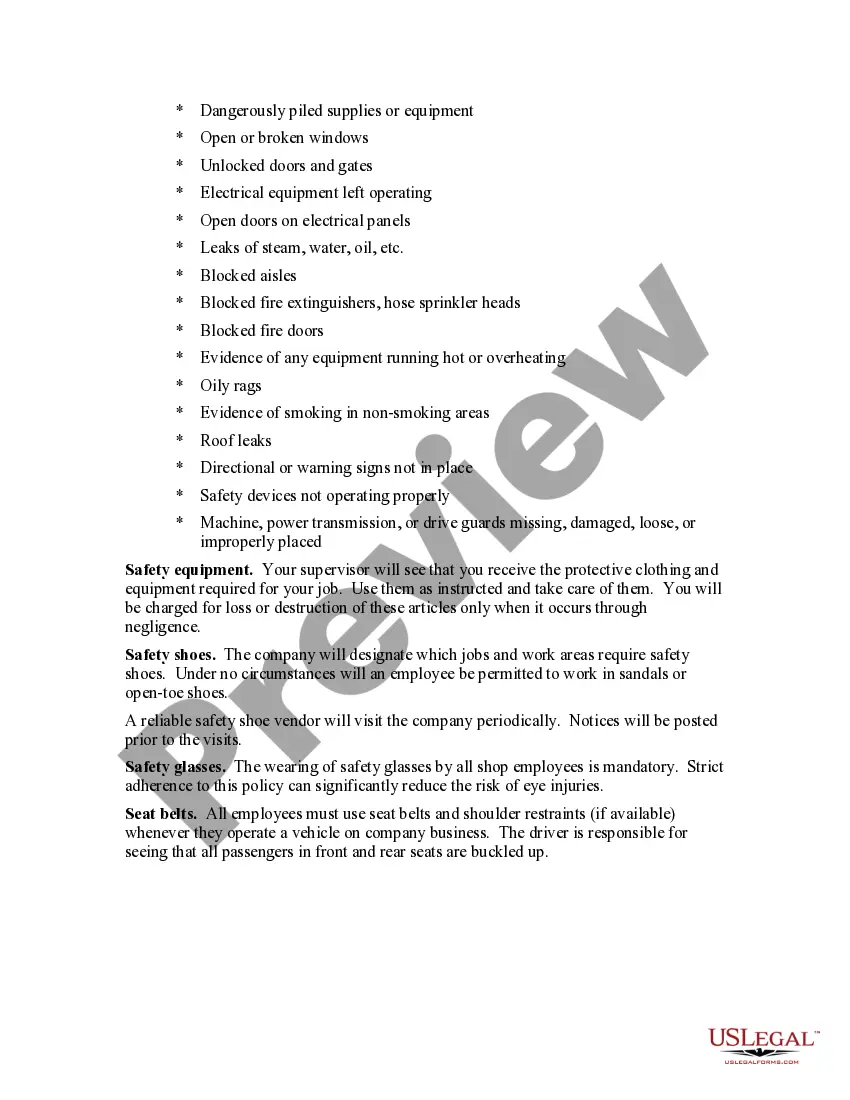

San Jose, California, workplace safety rules aim to maintain a secure and hazard-free environment for employees in various industries. These regulations are primarily implemented by the San Jose Department of Occupational Safety and Health (DOSH) to ensure compliance and prevent workplace accidents. Adhering to these safety rules is crucial to protect workers' health and prevent injuries or illnesses. The following are some essential workplace safety rules applicable in San Jose, California: 1. General Duty Clause: This clause stipulates that employers must provide their employees with a workplace free from recognized hazards that cause or are likely to cause death or serious physical harm. 2. Hazard Communication (HANSOM): HANSOM rules require employers to establish a comprehensive program to provide information and training regarding hazardous chemicals present in the workplace. Employers must also maintain proper labeling, safety data sheets (SDS), and implement an effective chemical safety plan. 3. Lockout/Ragout (LOT): These regulations require employers to establish procedures for hazardous energy control, commonly known as lockout/ragout. This ensures that workers are protected from unexpected releases of energy during equipment servicing or maintenance. 4. Respiratory Protection: Employers must implement a respiratory protection program if employees are exposed to harmful airborne contaminants or if oxygen levels are insufficient. This includes providing suitable respiratory equipment and training employees in proper usage. 5. Personal Protective Equipment (PPE): Employers must assess the workplace for potential hazards that require the use of PPE, such as safety glasses, helmets, gloves, or masks. They are obligated to provide appropriate PPE and train employees on its usage, maintenance, and limitations. 6. Fall Protection: When employees are exposed to potential falls from heights, employers must implement safeguards like guardrails, safety nets, or personal fall arrest systems. Workers involved in construction, maintenance, or other elevated tasks must be provided with fall protection equipment and training. 7. Electrical Safety: Employers must ensure that electrical systems and equipment are properly installed, maintained, and grounded to prevent electrical hazards. Employees should receive training on electrical safety, including recognizing potential risks and practicing proper procedures. 8. Machine Guarding: Employers are obligated to use appropriate machine guards for equipment that may pose hazards, such as rotating parts, in-running nip points, or pinch points. Guards must be in place and functioning properly to protect workers from potential injuries. 9. Ergonomics: Employers should strive to provide ergonomic workplaces, minimizing physical stress and strain on employees. They should make efforts to address ergonomic hazards through proper workstation setup, equipment design, and training on safe lifting techniques. 10. Workplace Violence Prevention: Employers must develop and implement a workplace violence prevention program to ensure employee safety. This involves conducting risk assessments, establishing emergency plans, and providing training on recognizing and handling violent situations. These San Jose, California, workplace safety rules encompass various aspects of employee well-being. Adhering to these regulations not only safeguards workers but also promotes productivity and fosters a sense of trust and dedication in the workplace.

San Jose California Workplace Safety Rules

Description

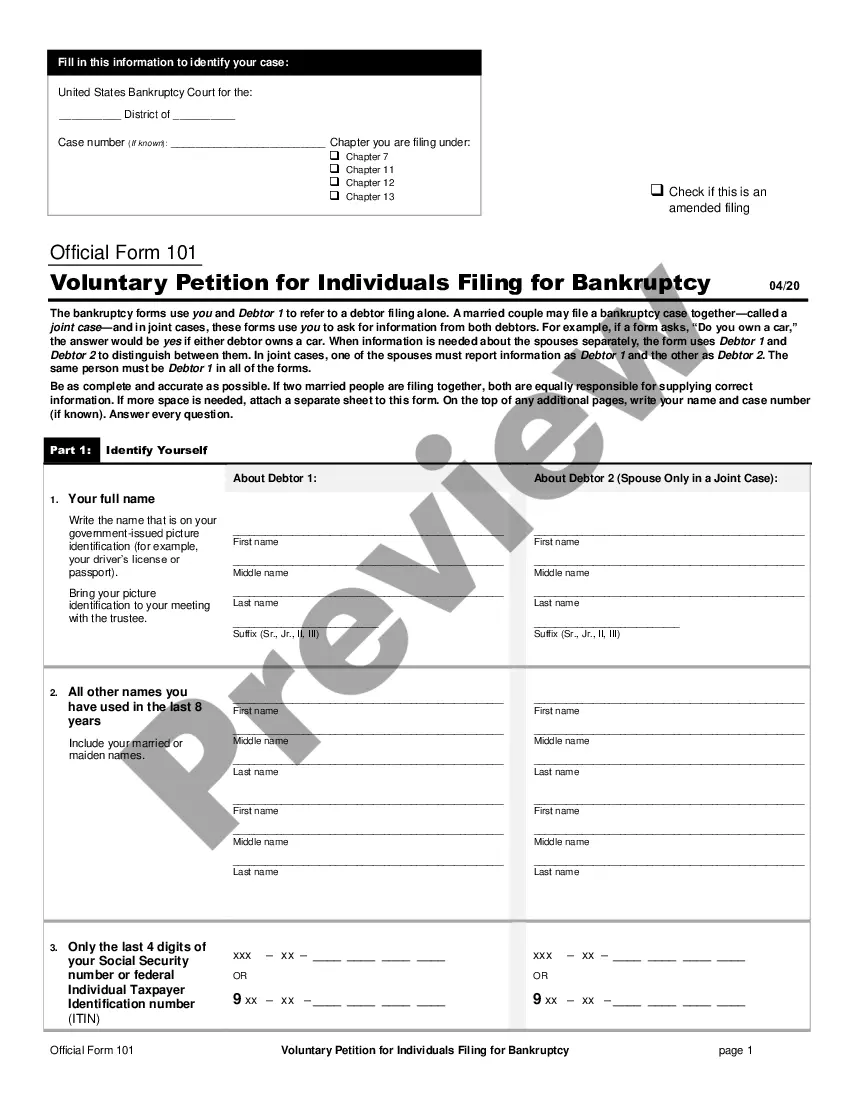

How to fill out San Jose California Workplace Safety Rules?

If you need to get a reliable legal document provider to obtain the San Jose Workplace Safety Rules, look no further than US Legal Forms. No matter if you need to start your LLC business or manage your asset distribution, we got you covered. You don't need to be knowledgeable about in law to locate and download the needed template.

- You can select from over 85,000 forms categorized by state/county and situation.

- The intuitive interface, variety of supporting resources, and dedicated support team make it easy to get and execute various paperwork.

- US Legal Forms is a trusted service providing legal forms to millions of users since 1997.

You can simply type to look for or browse San Jose Workplace Safety Rules, either by a keyword or by the state/county the form is created for. After locating needed template, you can log in and download it or save it in the My Forms tab.

Don't have an account? It's effortless to start! Simply find the San Jose Workplace Safety Rules template and take a look at the form's preview and description (if available). If you're confident about the template’s legalese, go ahead and click Buy now. Register an account and choose a subscription option. The template will be instantly available for download as soon as the payment is processed. Now you can execute the form.

Taking care of your law-related matters doesn’t have to be expensive or time-consuming. US Legal Forms is here to prove it. Our extensive variety of legal forms makes this experience less costly and more affordable. Set up your first company, arrange your advance care planning, draft a real estate contract, or complete the San Jose Workplace Safety Rules - all from the convenience of your home.

Sign up for US Legal Forms now!