The Allegheny Pennsylvania Maintenance Assistance — Technician Checklist is a comprehensive tool designed to assist maintenance technicians in overseeing and performing various maintenance tasks efficiently and effectively. It serves as a reliable guide for technicians working in Allegheny, Pennsylvania, to ensure that all maintenance activities are carried out seamlessly. This checklist covers a wide range of maintenance tasks, including equipment inspection, repairs, troubleshooting, and preventive maintenance measures. It provides step-by-step instructions, ensuring that technicians don't overlook critical tasks and adhere to safety protocols. By following this checklist, technicians can ensure that all maintenance duties are completed on time and within the required standards. The Allegheny Pennsylvania Maintenance Assistance — Technician Checklist can be applied across various industries and sectors, catering to different types of maintenance requirements. Some common types of checklists based on specific needs include: 1. Equipment Maintenance Checklist: This checklist specifically focuses on the inspection, repair, and maintenance of equipment, such as machinery, appliances, vehicles, or any other mechanical devices. It helps technicians identify potential issues, perform necessary repairs, and ensure optimal functionality of the equipment. 2. Building Maintenance Checklist: This checklist is tailored for technicians responsible for the maintenance of buildings, facilities, or structures. It covers tasks such as plumbing, electrical systems, HVAC, structural integrity, and general repairs. Technicians can efficiently perform routine maintenance, identify potential issues, and provide necessary fixes to maintain a safe and functional environment. 3. Preventive Maintenance Checklist: This checklist emphasizes proactive maintenance to prevent potential breakdowns or failures. It includes regular inspections, lubrication, cleaning, replacement of worn-out parts, and other measures aimed at extending the lifespan and efficiency of equipment. Technicians can follow this checklist to schedule preventive maintenance tasks and reduce unforeseen damages. 4. Safety and Compliance Checklist: This checklist focuses on ensuring that maintenance activities adhere to safety regulations and compliance standards. It covers procedures related to personal protective equipment (PPE), hazardous material handling, lockout/ragout protocols, and workplace safety guidelines. Technicians can refer to this checklist to ensure that maintenance work conforms to all necessary safety procedures. The Allegheny Pennsylvania Maintenance Assistance — Technician Checklist, in its various types, plays a crucial role in streamlining maintenance operations and minimizing downtime. By utilizing these checklists, maintenance technicians can ensure that tasks are completed systematically, potential issues are proactively addressed, and safety standards are maintained, ultimately enhancing overall operational efficiency.

Allegheny Pennsylvania Maintenance Assistance - Technician Checklist

Description

How to fill out Allegheny Pennsylvania Maintenance Assistance - Technician Checklist?

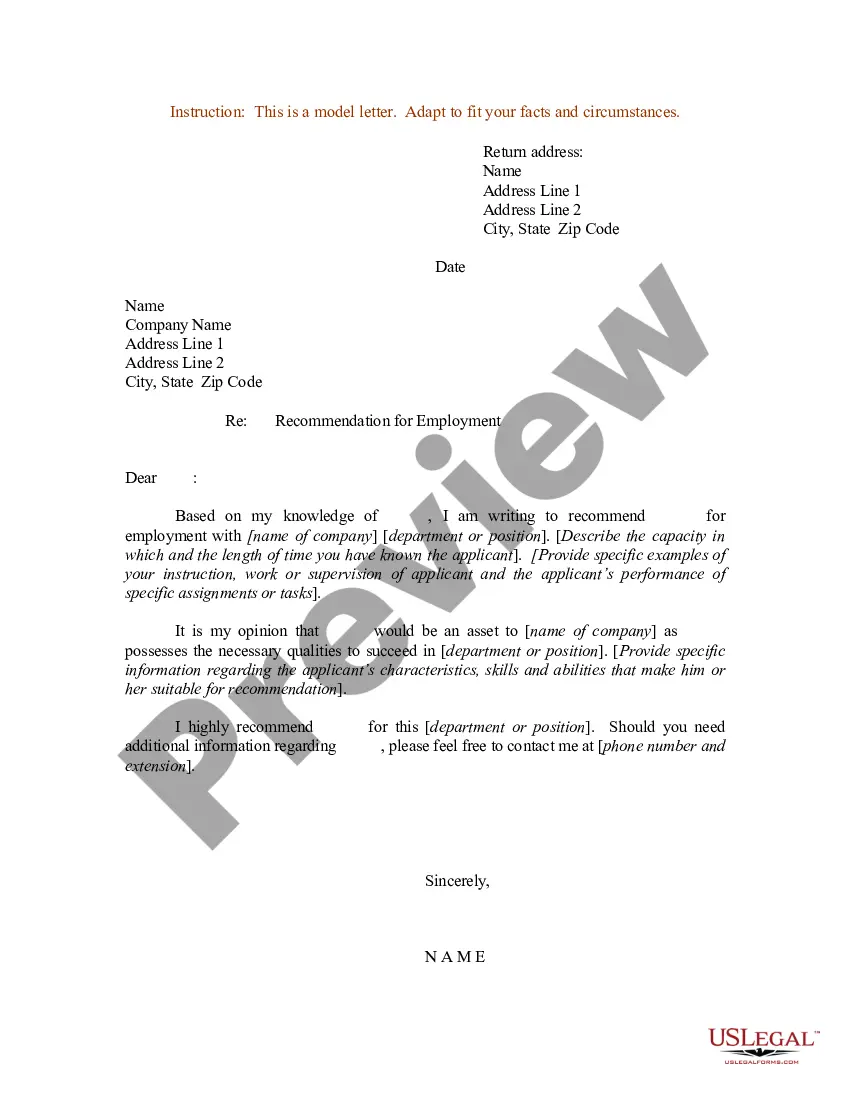

Preparing legal documentation can be cumbersome. Besides, if you decide to ask a legal professional to draft a commercial contract, documents for ownership transfer, pre-marital agreement, divorce papers, or the Allegheny Maintenance Assistance - Technician Checklist, it may cost you a lot of money. So what is the most reasonable way to save time and money and draft legitimate documents in total compliance with your state and local laws and regulations? US Legal Forms is an excellent solution, whether you're searching for templates for your personal or business needs.

US Legal Forms is the most extensive online catalog of state-specific legal documents, providing users with the up-to-date and professionally verified templates for any use case accumulated all in one place. Consequently, if you need the latest version of the Allegheny Maintenance Assistance - Technician Checklist, you can easily find it on our platform. Obtaining the papers takes a minimum of time. Those who already have an account should check their subscription to be valid, log in, and pick the sample by clicking on the Download button. If you haven't subscribed yet, here's how you can get the Allegheny Maintenance Assistance - Technician Checklist:

- Glance through the page and verify there is a sample for your area.

- Check the form description and use the Preview option, if available, to ensure it's the sample you need.

- Don't worry if the form doesn't suit your requirements - search for the correct one in the header.

- Click Buy Now when you find the needed sample and pick the best suitable subscription.

- Log in or register for an account to pay for your subscription.

- Make a transaction with a credit card or via PayPal.

- Choose the file format for your Allegheny Maintenance Assistance - Technician Checklist and download it.

Once done, you can print it out and complete it on paper or upload the template to an online editor for a faster and more convenient fill-out. US Legal Forms enables you to use all the documents ever obtained multiple times - you can find your templates in the My Forms tab in your profile. Try it out now!