Philadelphia Pennsylvania Maintenance Assistance — Technician Checklist is a comprehensive checklist designed to assist technicians in efficiently and effectively carrying out maintenance tasks in Philadelphia, Pennsylvania. This checklist is tailored to the unique needs and requirements of the region, ensuring maximum productivity and accuracy. Keywords: Philadelphia Pennsylvania, maintenance assistance, technician checklist, comprehensive checklist, maintenance tasks, efficiency, effectiveness, tailored, unique needs, productivity, accuracy. Different Types of Philadelphia Pennsylvania Maintenance Assistance — Technician Checklists: 1. Building Maintenance Checklist: This checklist focuses on various maintenance tasks related to buildings such as HVAC systems, electrical systems, plumbing, and general facility maintenance. 2. Equipment Maintenance Checklist: This checklist guides technicians through the regular inspection, servicing, and repair of equipment used in various industries, including manufacturing, healthcare, and hospitality. 3. Vehicle Maintenance Checklist: This checklist is specifically designed for technicians responsible for maintaining a fleet of vehicles, ensuring that all vehicles remain in optimal condition and meeting regulatory standards. 4. Power Plant Maintenance Checklist: For technicians working in power plants, this checklist is crucial for ensuring the smooth operation and safety of the facility. It includes tasks like equipment inspections, preventive maintenance, and repair procedures. 5. Facility Safety Checklist: Safety is a top priority in any maintenance role, and this checklist helps technicians identify potential hazards, assess safety procedures, and implement corrective measures to maintain a safe working environment. 6. Scheduled Maintenance Checklist: This checklist outlines routine maintenance tasks that need to be performed on a regular schedule to prevent equipment or facility failures. It includes activities like lubrication, filter replacement, and inspections. 7. Emergency Maintenance Checklist: Technicians must be prepared for unpredictable situations, and this checklist addresses emergency repair procedures, response protocols, and troubleshooting techniques to minimize downtime during critical situations. 8. Environmental Maintenance Checklist: For technicians working in environmentally-sensitive areas or industries, this checklist ensures compliance with regulations and protocols related to waste management, pollution prevention, and resource conservation. These various types of Philadelphia Pennsylvania Maintenance Assistance — Technician Checklists provide technicians with the necessary guidance and structure to effectively execute their maintenance tasks in the region, promoting efficiency, safety, and productivity.

Philadelphia Pennsylvania Maintenance Assistance - Technician Checklist

Description

How to fill out Philadelphia Pennsylvania Maintenance Assistance - Technician Checklist?

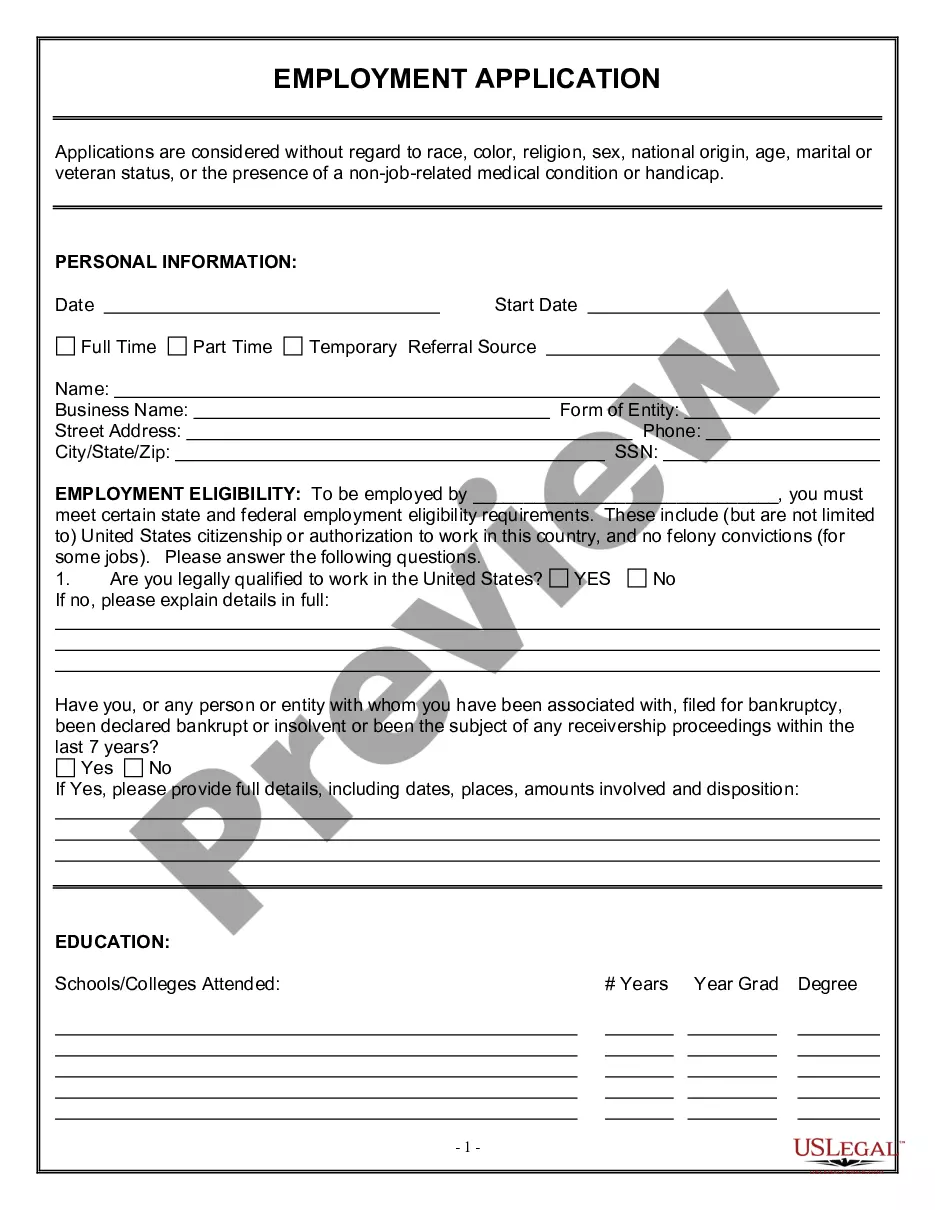

Whether you plan to start your business, enter into an agreement, apply for your ID update, or resolve family-related legal issues, you must prepare specific paperwork meeting your local laws and regulations. Finding the right papers may take a lot of time and effort unless you use the US Legal Forms library.

The service provides users with more than 85,000 expertly drafted and checked legal documents for any individual or business case. All files are collected by state and area of use, so opting for a copy like Philadelphia Maintenance Assistance - Technician Checklist is fast and simple.

The US Legal Forms website users only need to log in to their account and click the Download key next to the required template. If you are new to the service, it will take you several additional steps to obtain the Philadelphia Maintenance Assistance - Technician Checklist. Adhere to the guidelines below:

- Make certain the sample meets your individual needs and state law requirements.

- Look through the form description and check the Preview if there’s one on the page.

- Use the search tab specifying your state above to find another template.

- Click Buy Now to obtain the file when you find the right one.

- Opt for the subscription plan that suits you most to proceed.

- Log in to your account and pay the service with a credit card or PayPal.

- Download the Philadelphia Maintenance Assistance - Technician Checklist in the file format you prefer.

- Print the copy or fill it out and sign it electronically via an online editor to save time.

Forms provided by our website are reusable. Having an active subscription, you are able to access all of your earlier acquired paperwork at any time in the My Forms tab of your profile. Stop wasting time on a endless search for up-to-date official documents. Sign up for the US Legal Forms platform and keep your paperwork in order with the most extensive online form library!