Title: Mecklenburg North Carolina Maintenance Engineer Checklist: A Comprehensive Guide for Efficient Operations Introduction: As a maintenance engineer in Mecklenburg, North Carolina, ensuring the smooth and continuous functioning of a facility or building is crucial. The Mecklenburg North Carolina Maintenance Engineer Checklist serves as a comprehensive guide to streamline maintenance activities, maximize operational efficiency, and minimize downtime. This detailed checklist encompasses different categories and examples, tailored to the specific needs of various industries and types of facilities within the region. 1. Electrical Systems Maintenance Checklist: — Inspect and maintain electrical panels, circuits, switches, and outlets. — Test and ensure proper functioning of emergency power systems. — Regularly check and calibrate electrical equipment, such as transformers and generators. — Verify the integrity of electrical wiring, cables, and grounding systems. — Document and address any electrical safety hazards promptly. 2. HVAC Systems Maintenance Checklist: — Clean and replace air filters regularly to maintain indoor air quality. — Inspect and service heating, ventilation, and air conditioning (HVAC) units. — Monitor and adjust temperature and humidity levels as per requirements. — Check and maintain the functionality of thermostats, fans, and dampers. — Conduct preventive maintenance and lubrication of HVAC components. 3. Plumbing Systems Maintenance Checklist: — Inspect and maintain plumbing fixtures, pipes, and drains. — Test and maintain water pressure and temperature control systems. — Locate and repair any leaks or drips promptly. — Clean drains and sewage systems to prevent blockages. — Ensure the availability of backup water supplies, especially for critical areas. 4. Fire Safety and Security Systems Maintenance Checklist: — Test and maintain fire alarms, smoke detectors, and sprinkler systems. — Inspect and maintain fire extinguishers, ensuring proper functioning and accessibility. — Verify the functionality of security systems, including surveillance cameras and access control systems. — Regularly monitor and replace batteries in smoke detectors and other safety devices. — Conduct periodic drills to ensure proper evacuation procedures. 5. Structural and Building Maintenance Checklist: — Inspect the building's exterior for cracks, leaks, or signs of damage. — Regularly clean and maintain gutters, downspouts, and roof drains. — Monitor and maintain structural integrity, such as walls, floors, and foundations. — Address any pest control issues promptly. — Conduct routine checks on elevators, escalators, and other building-specific systems. 6. Equipment and Machinery Maintenance Checklist: — Develop a preventive maintenance schedule for all machinery and equipment. — Lubricate moving parts, clean filters, and ensure optimal operation. — Inspect and maintain conveyors, motors, gears, and bearings. — Test and calibrate measuring instruments and control systems. — Document and address equipment malfunctions or abnormalities promptly. Conclusion: The Mecklenburg North Carolina Maintenance Engineer Checklist provides a comprehensive and customized resource for maintenance engineers operating in different industries throughout the region. By following this checklist diligently, maintenance engineers can enhance the reliability, longevity, and efficiency of infrastructure, equipment, and systems. Taking a proactive approach to maintenance can significantly reduce operational downtime, increase safety, and contribute to the overall success of any facility in Mecklenburg, North Carolina.

Mecklenburg North Carolina Maintenance Engineer Checklist

Description

How to fill out Mecklenburg North Carolina Maintenance Engineer Checklist?

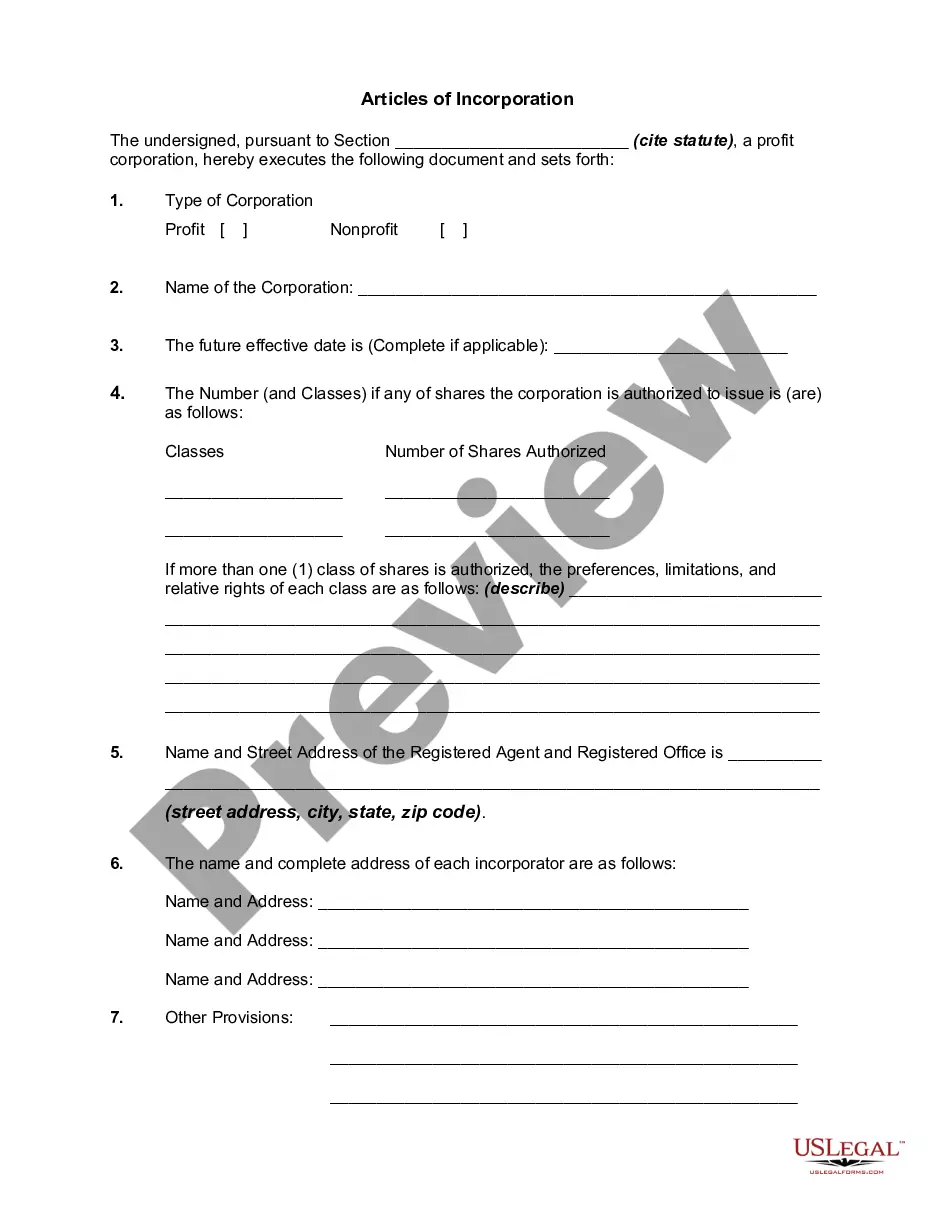

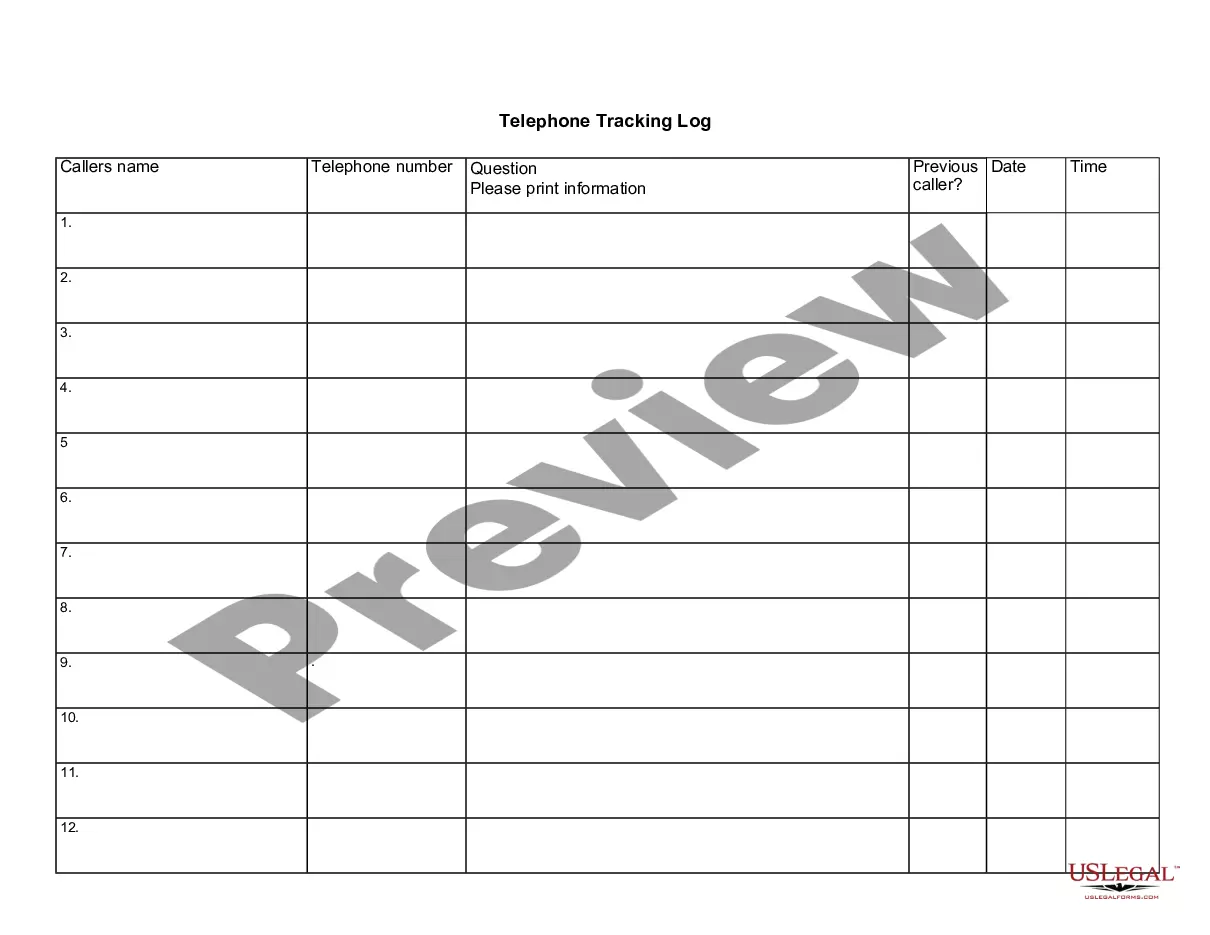

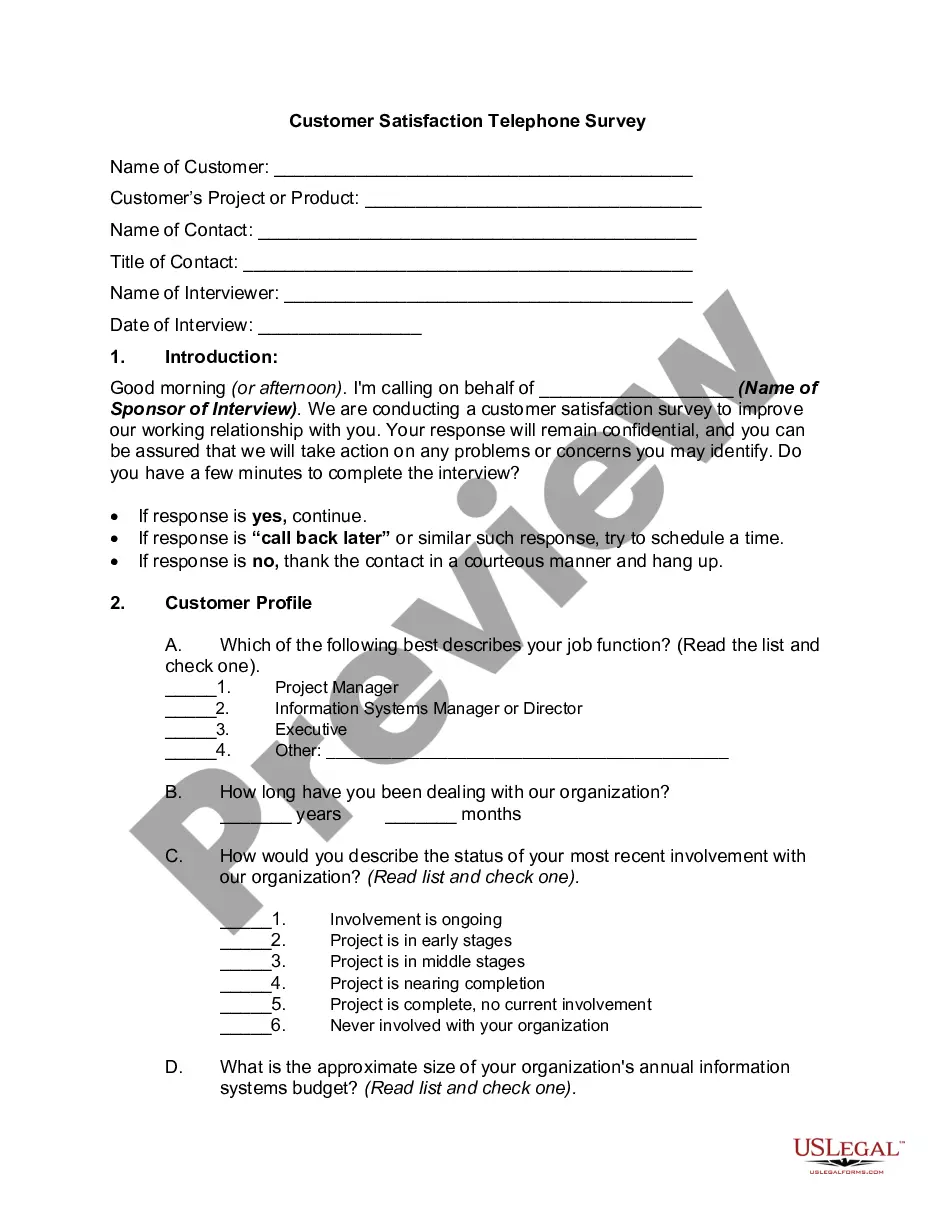

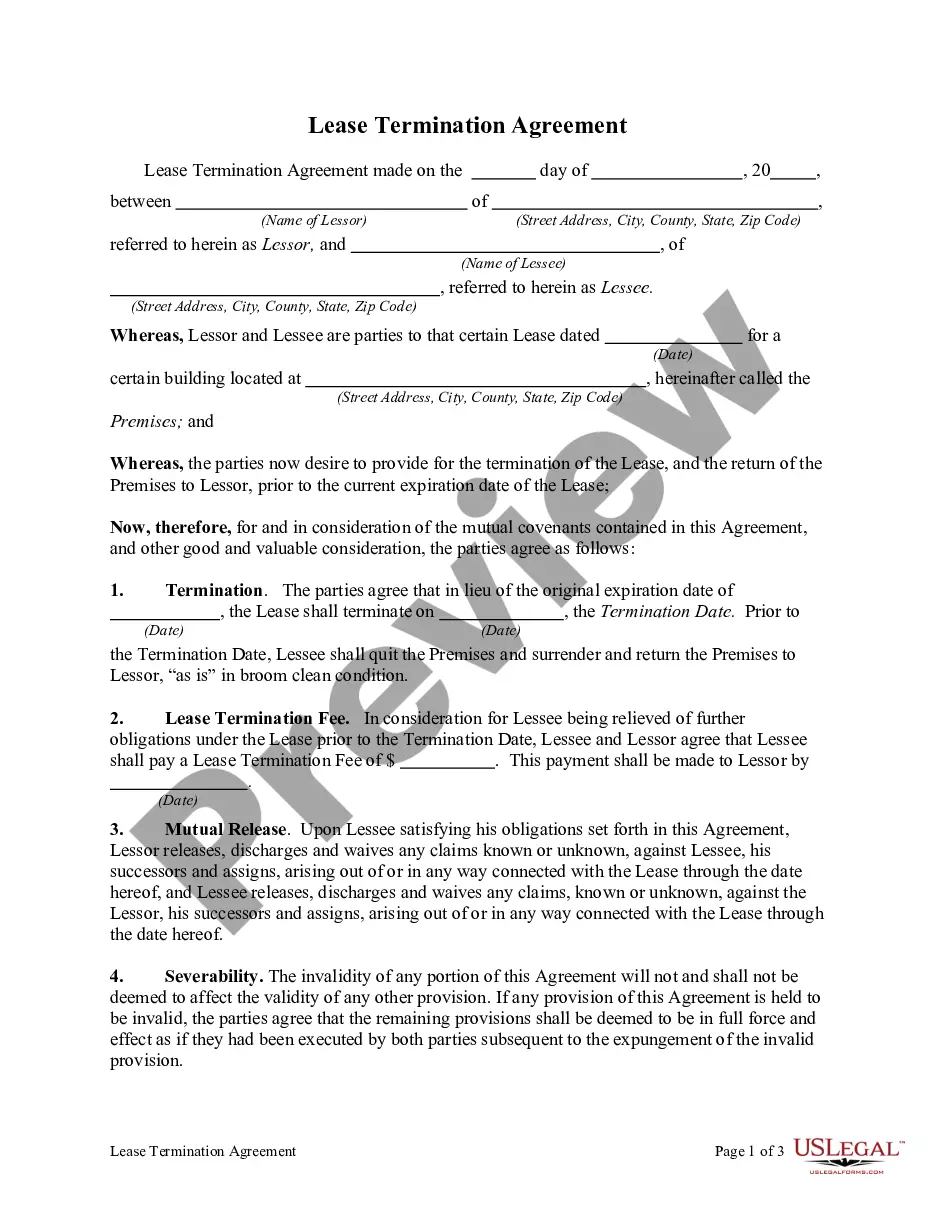

Whether you intend to start your company, enter into an agreement, apply for your ID renewal, or resolve family-related legal concerns, you must prepare certain paperwork corresponding to your local laws and regulations. Finding the right papers may take a lot of time and effort unless you use the US Legal Forms library.

The platform provides users with more than 85,000 professionally drafted and verified legal documents for any personal or business occasion. All files are collected by state and area of use, so opting for a copy like Mecklenburg Maintenance Engineer Checklist is quick and simple.

The US Legal Forms website users only need to log in to their account and click the Download key next to the required form. If you are new to the service, it will take you a couple of more steps to obtain the Mecklenburg Maintenance Engineer Checklist. Adhere to the guidelines below:

- Make certain the sample meets your individual needs and state law regulations.

- Look through the form description and check the Preview if available on the page.

- Make use of the search tab providing your state above to find another template.

- Click Buy Now to get the file when you find the proper one.

- Choose the subscription plan that suits you most to proceed.

- Log in to your account and pay the service with a credit card or PayPal.

- Download the Mecklenburg Maintenance Engineer Checklist in the file format you need.

- Print the copy or complete it and sign it electronically via an online editor to save time.

Forms provided by our website are reusable. Having an active subscription, you can access all of your previously purchased paperwork at any time in the My Forms tab of your profile. Stop wasting time on a constant search for up-to-date official documentation. Sign up for the US Legal Forms platform and keep your paperwork in order with the most comprehensive online form collection!