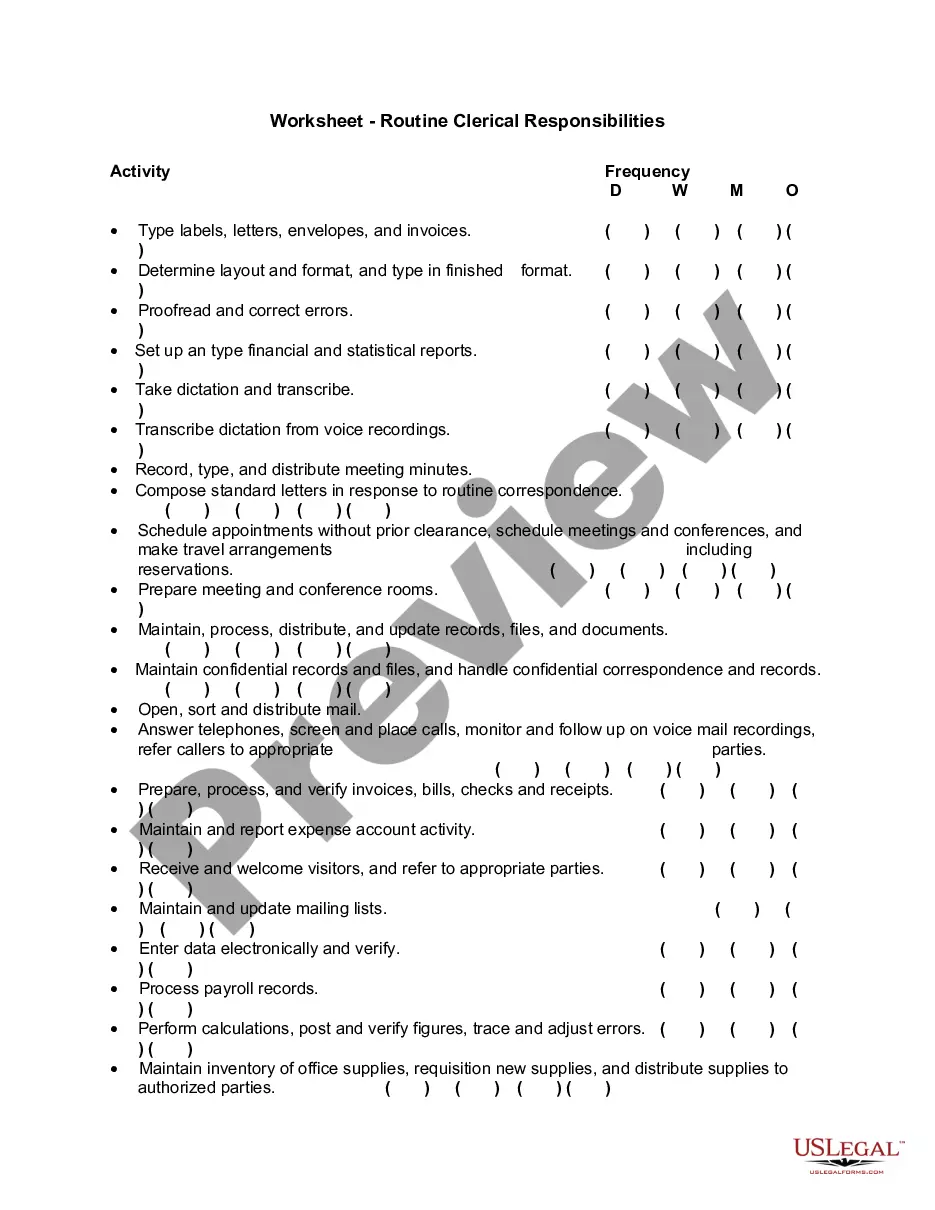

Tarrant Texas Maintenance Supervisor Checklist: Streamlining Maintenance Operations A Tarrant Texas Maintenance Supervisor Checklist is an essential tool that ensures smooth and efficient management of maintenance operations in various industries and sectors. It serves as a comprehensive guide for supervisors to track, schedule, and prioritize maintenance tasks, minimizing downtime, and maximizing the lifespan of equipment and facilities. Keywords: Tarrant Texas, Maintenance Supervisor Checklist, maintenance operations, smooth management, task scheduling, prioritization, equipment lifespan, minimize downtime Different Types of Tarrant Texas Maintenance Supervisor Checklists: 1. Facility Maintenance Checklist: This checklist focuses on inspecting, maintaining, and repairing the physical infrastructure of a facility, such as buildings, electrical systems, plumbing, HVAC, ventilation, and safety equipment. It includes tasks such as checking for leaks, replacing filters, testing emergency systems, and ensuring compliance with safety regulations. 2. Equipment Maintenance Checklist: This type of checklist primarily targets machinery and equipment within a facility or organization. It outlines maintenance tasks like lubrication, calibration, routine inspections, cleaning, and repair work. The checklist aids supervisors in promptly identifying potential issues, conducting preventive maintenance, and reducing equipment failure. 3. Preventive Maintenance Checklist: Preventive maintenance is key to avoiding costly breakdowns and extending the lifespan of assets. This type of checklist helps supervisors plan and execute regular inspections, replacements, and adjustments of equipment and systems. It includes tasks like oil changes, filter replacements, bearing inspections, computer updates, and software patches. 4. Safety Inspection Checklist: Ensuring a safe working environment is vital for any organization. A safety inspection checklist helps supervisors identify potential hazards, maintain compliance with safety regulations, and prevent accidents. This checklist covers areas like fire safety, emergency exits, electrical hazards, first-aid supplies, and safety training documentation. 5. Routine Maintenance Checklist: Routine maintenance involves repetitive tasks that need to be performed at regular intervals. It includes activities such as cleaning, dusting, organizing, restocking, and visual inspections. This checklist helps supervisors create a habit of consistent maintenance to keep facilities and equipment in optimal condition. By leveraging a Tarrant Texas Maintenance Supervisor Checklist, supervisors can effectively manage maintenance activities, address issues proactively, allocate resources efficiently, and optimize the overall productivity of their facility or organization.

Tarrant Texas Maintenance Supervisor Checklist

Description

How to fill out Tarrant Texas Maintenance Supervisor Checklist?

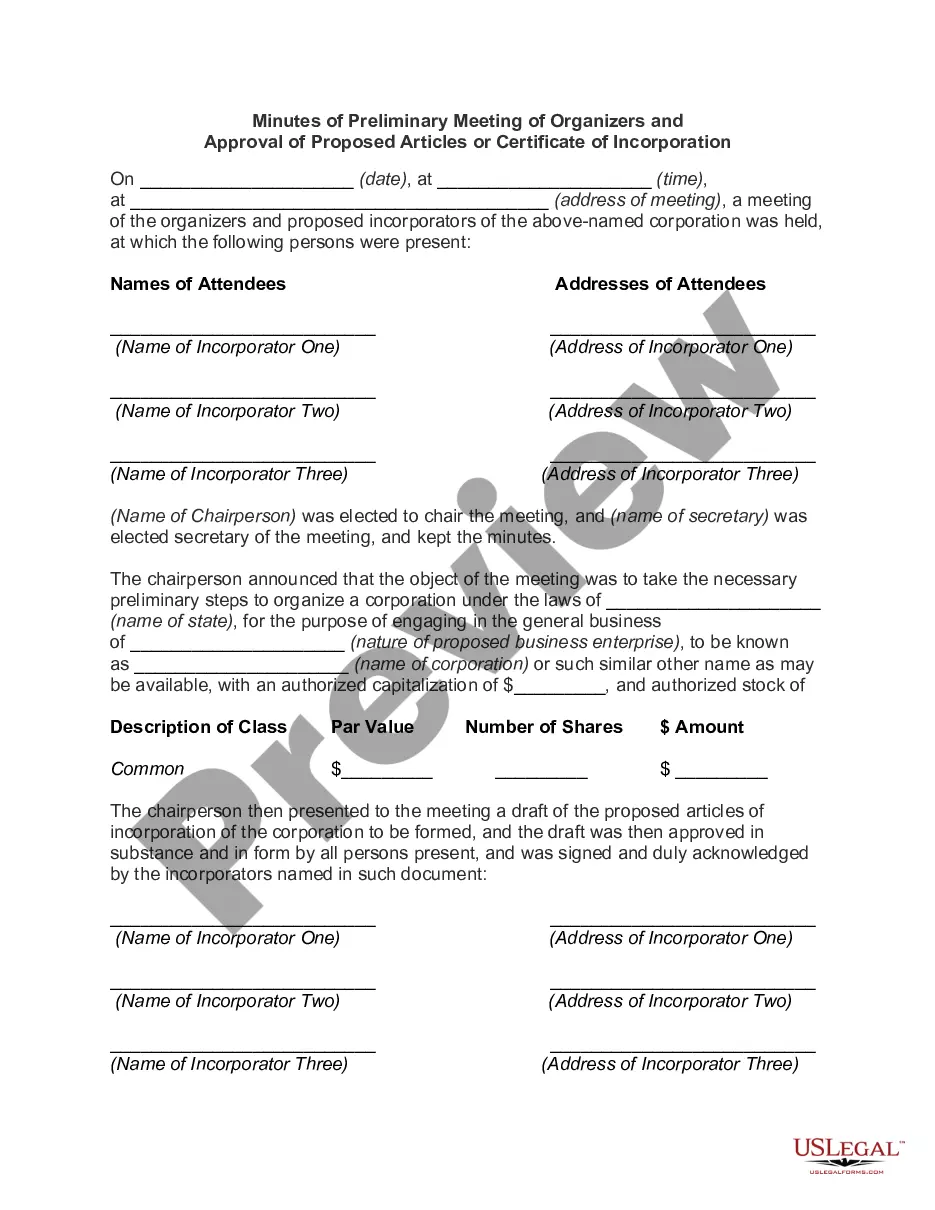

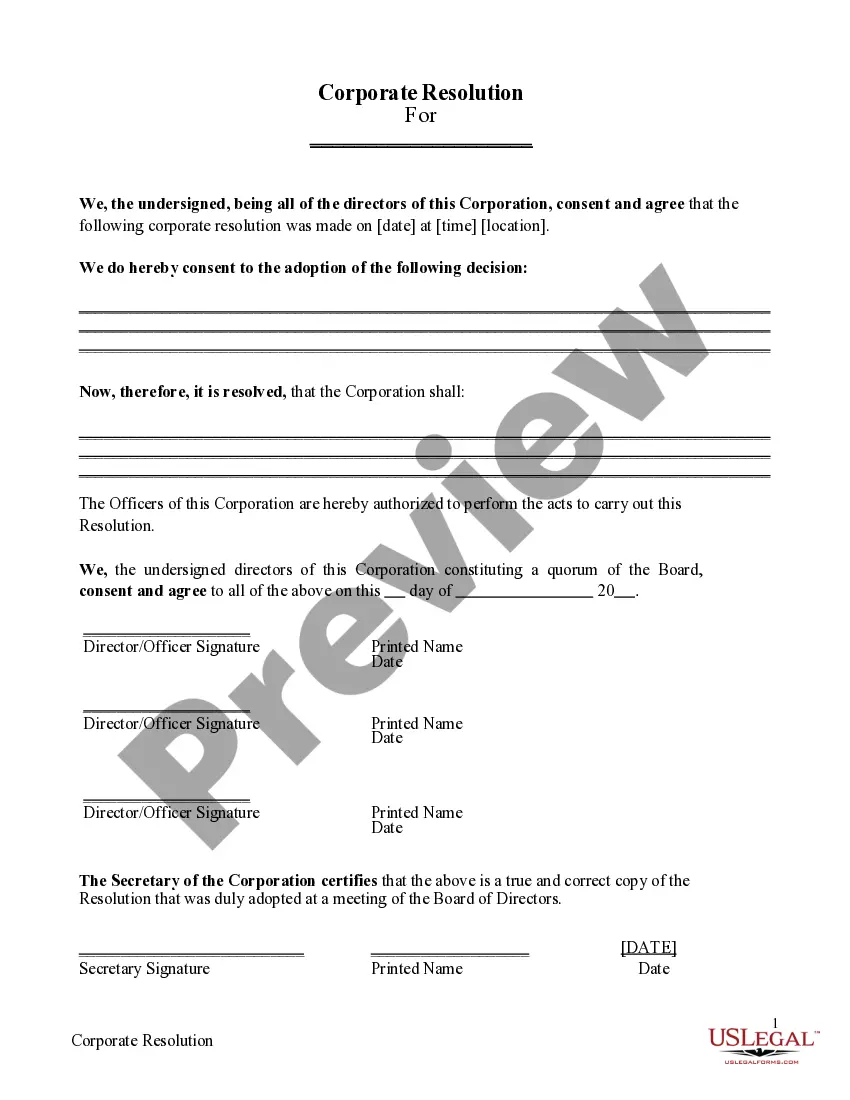

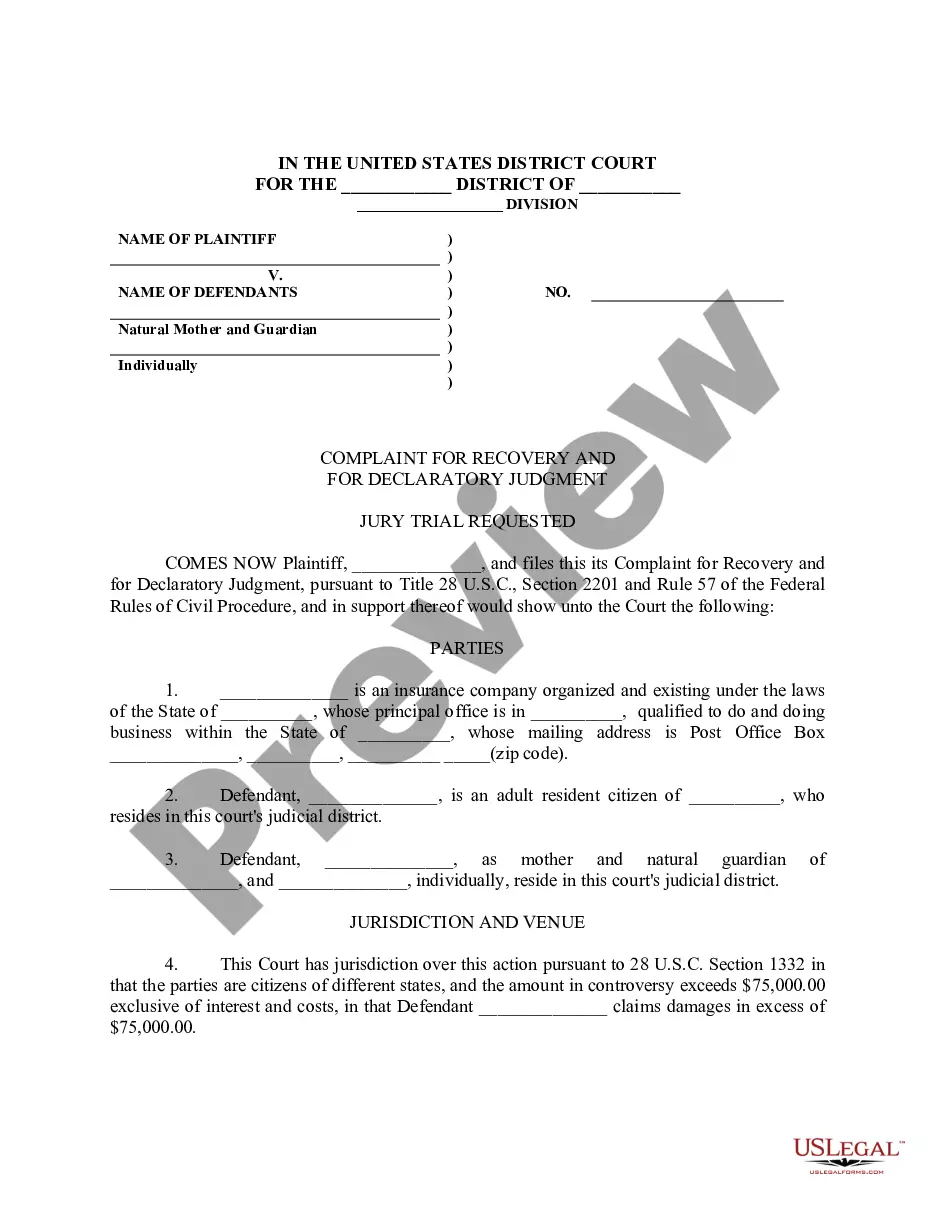

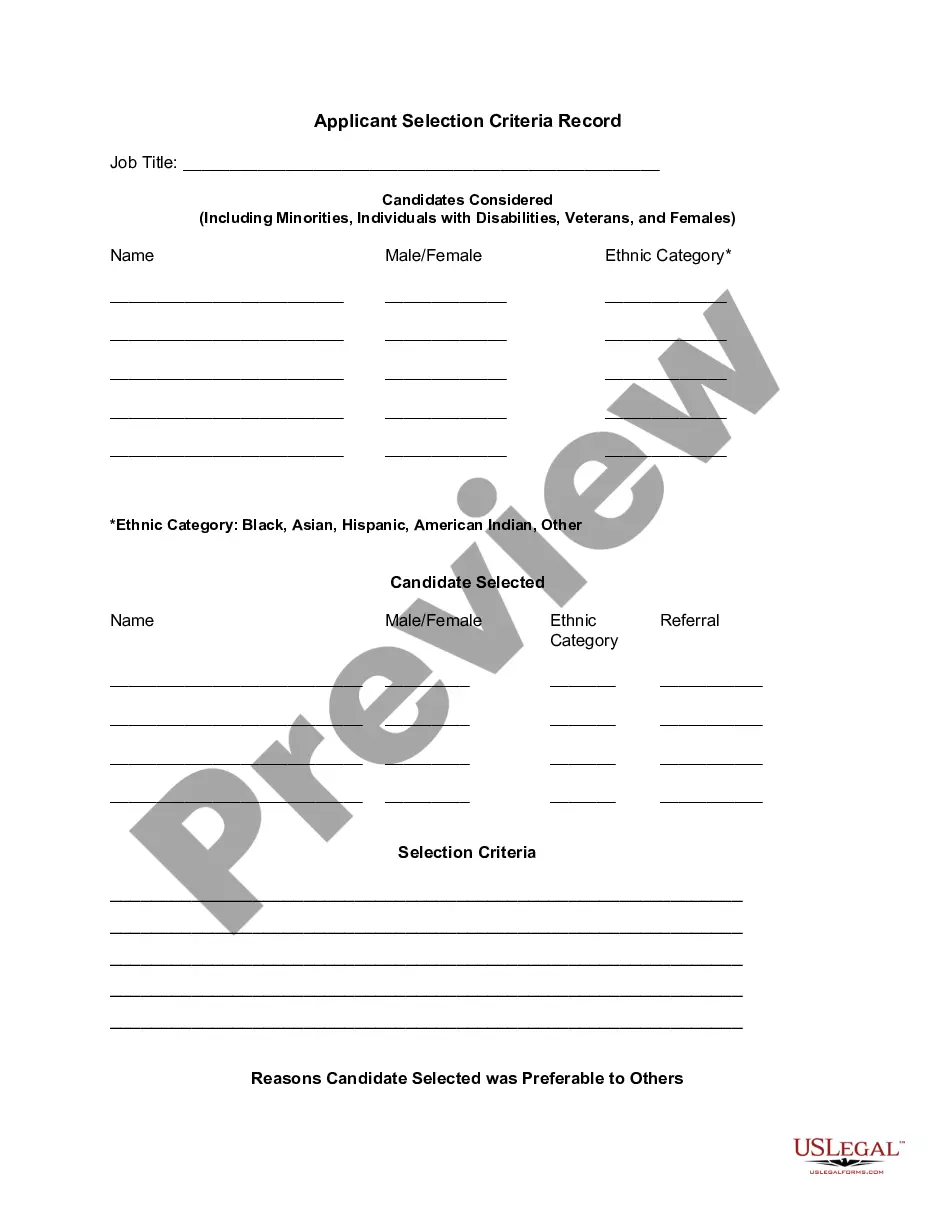

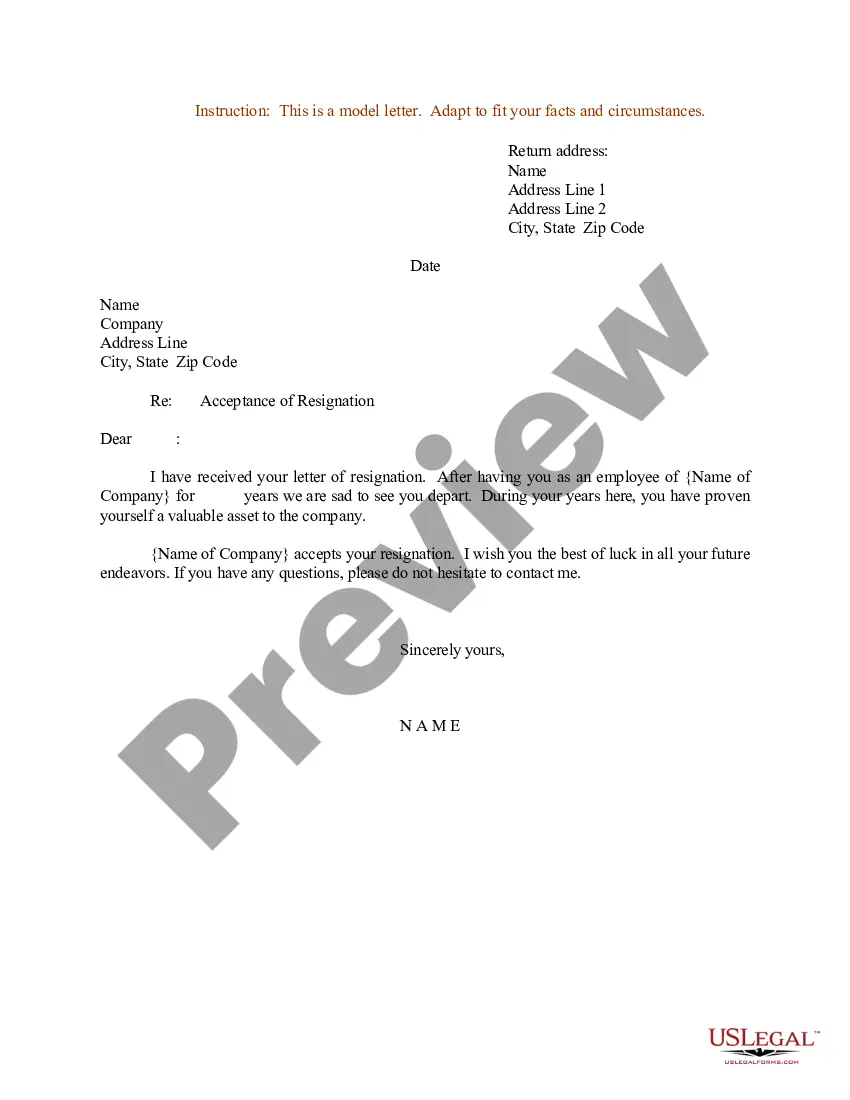

Preparing legal documentation can be burdensome. Besides, if you decide to ask a lawyer to draft a commercial agreement, papers for proprietorship transfer, pre-marital agreement, divorce paperwork, or the Tarrant Maintenance Supervisor Checklist, it may cost you a lot of money. So what is the most reasonable way to save time and money and draw up legitimate documents in total compliance with your state and local regulations? US Legal Forms is an excellent solution, whether you're looking for templates for your individual or business needs.

US Legal Forms is the most extensive online catalog of state-specific legal documents, providing users with the up-to-date and professionally verified templates for any scenario collected all in one place. Therefore, if you need the latest version of the Tarrant Maintenance Supervisor Checklist, you can easily locate it on our platform. Obtaining the papers takes a minimum of time. Those who already have an account should check their subscription to be valid, log in, and select the sample with the Download button. If you haven't subscribed yet, here's how you can get the Tarrant Maintenance Supervisor Checklist:

- Glance through the page and verify there is a sample for your area.

- Examine the form description and use the Preview option, if available, to ensure it's the template you need.

- Don't worry if the form doesn't suit your requirements - search for the correct one in the header.

- Click Buy Now when you find the needed sample and choose the best suitable subscription.

- Log in or register for an account to purchase your subscription.

- Make a payment with a credit card or through PayPal.

- Opt for the file format for your Tarrant Maintenance Supervisor Checklist and download it.

When done, you can print it out and complete it on paper or import the template to an online editor for a faster and more practical fill-out. US Legal Forms allows you to use all the documents ever obtained multiple times - you can find your templates in the My Forms tab in your profile. Give it a try now!

Form popularity

FAQ

Visually inspect the underside of the engine hoses, pulleys and belts for cracks. Look for any sign of engine oil, transmission fluid or any other fluid leaks. Check wheel bearing wear. Brake pads and brake lines.

These items should include the model & serial number, maintenance guidelines, manuals and replacement parts. You should also document the expected downtimes of equipment, cost of parts, and the amount of expected downtime.

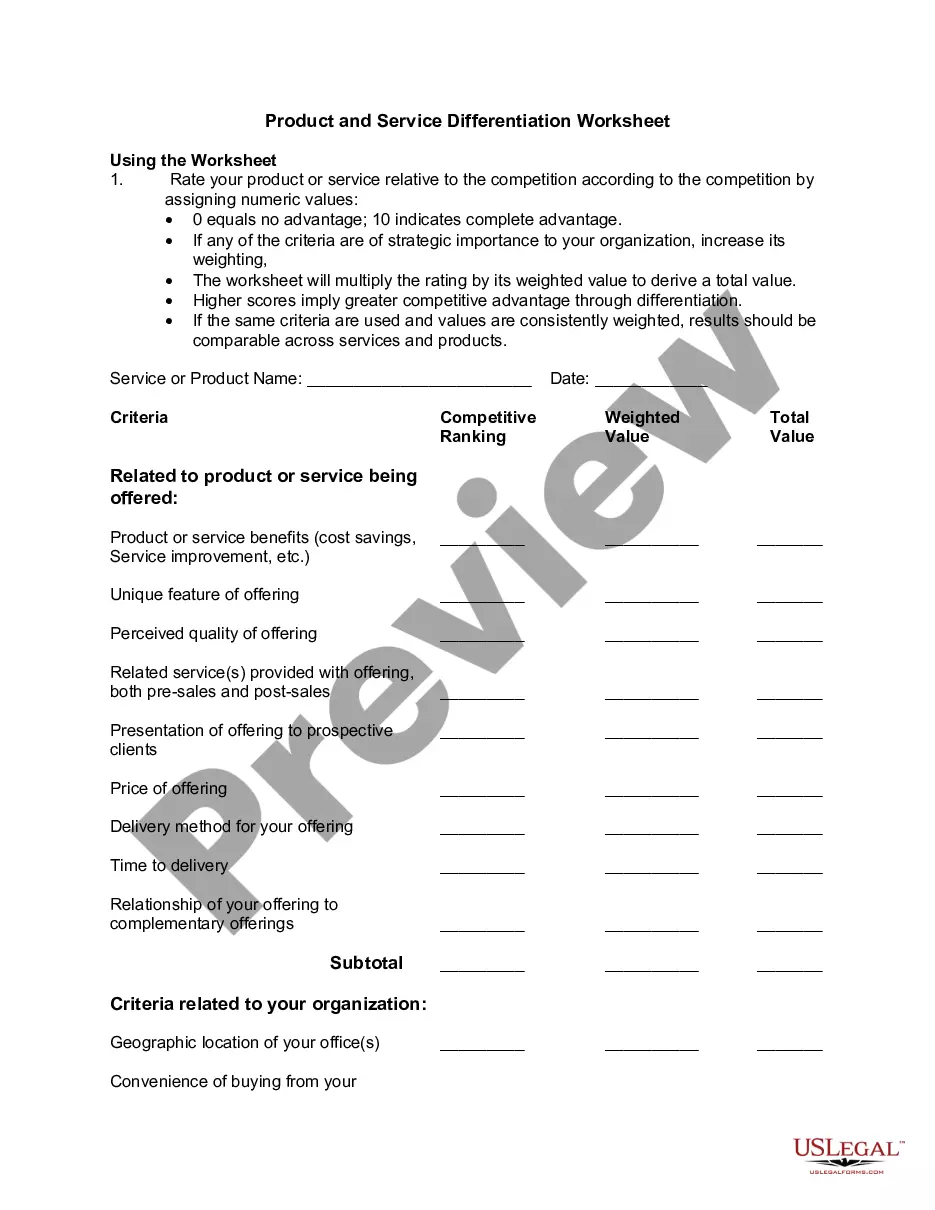

A maintenance checklist is usually a document that contains the items that need to be or that have been reviewed. These items will vary depending upon what type of object is being analyzed. The items on a maintenance checklist can also be affected by the category of maintenance.

The Ultimate Preventive Maintenance Checklist Ensure that machinery is clear of debris, before and after every shift. Wipe machine surfaces of lubricant, dirt and other loose debris each day. Regularly inspect tools for sharpness. Check for and replace worn or damaged tools.

What's a maintenance inspection? As a key component of a maintenance program, inspections include tasks that check the condition of equipment and determine what tools, materials, and labor are required to service them. A maintenance inspection is the process of evaluation the condition of equipment or machines.

What are Maintenance Checklists? Maintenance checklists and logbooks are tools used by technicians to document equipment maintenance inspections. Equipment maintenance involves the continuous process of checking, repairing, and servicing operating equipment to ensure businesses can operate without interruption.

An effective preventative maintenance schedule avoids equipment failure, which can represent not only decreased productivity but also workplace safety risks to employees. In addition, a preventive maintenance checklist reduces human errors and contains important safety instructions that minimize the chance of injury.

Check walls, ceilings, and floors for damage, leaks, or other deterioration. Be sure to remove hazards and ensure proper operation of doors and locks. Restroom areas should be inspected for problems, and alarms should be tested.

Preventive maintenance involves the systematic inspection of equipment where potential problems are detected and corrected in order to prevent equipment failure before it happens.