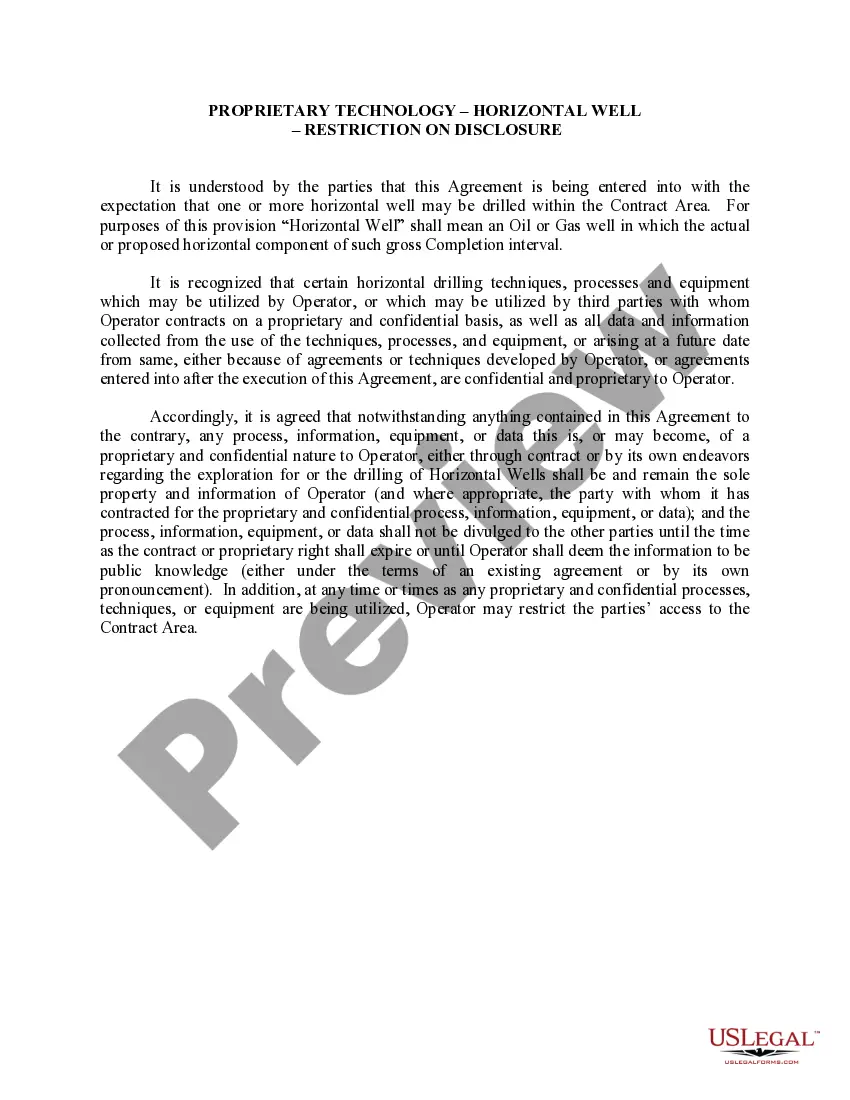

This provision is for an Agreement where there is the expectation that one or more horizontal wells may be drilled within the Contract Area. This section addresses the drilling of Horizontal Wells and that they shall remain the sole property and information of the Operator

San Bernardino, California, is home to various types of proprietary technology related to horizontal well operations, which are subject to certain restrictions on disclosure. This pioneering technology has revolutionized oil and gas extraction methods, improving efficiency, and maximizing productivity in the industry. One type of San Bernardino California proprietary technology is the Horizontal Well Optimization System (TWOS). This system utilizes advanced data analytics, artificial intelligence, and machine learning algorithms to optimize every aspect of horizontal well drilling and production. TWOS enhances reservoir characterization, well bore placement, hydraulic fracturing, and production monitoring, resulting in increased hydrocarbon recovery and cost savings for operators. Another type of proprietary technology in San Bernardino California is the Proactive Well Integrity Management System (SWIMS). SWIMS is designed to detect and prevent well integrity issues in horizontal wells. It employs advanced monitoring techniques, including real-time data acquisition and analysis, to identify potential problems such as casing failures, leaks, or cement degradation. By addressing these issues promptly, operators can mitigate environmental risks, reduce non-productive time, and prevent costly well interventions. Moreover, San Bernardino is also known for its innovative Down hole Tool Development (DID) technology. DID involve the design, development, and manufacturing of specialized tools used in horizontal well operations. These tools include drilling motors, rotary steerable systems, and measurement while drilling (MID) tools. The use of advanced materials and cutting-edge engineering techniques ensures the reliability, durability, and efficiency of these tools, ultimately improving well bore placement accuracy and overall drilling performance. Due to the proprietary nature of these technologies, strict restrictions on disclosure apply, aiming to protect intellectual property and maintain a competitive advantage. Non-disclosure agreements (NDAs) are commonly used to safeguard trade secrets and ensure that the technology remains confidential within the respective companies or organizations. San Bernardino California's proprietary technology related to horizontal well operations, including the Horizontal Well Optimization System, Proactive Well Integrity Management System, and Down hole Tool Development, has significantly contributed to enhancing the efficiency, safety, and environmental sustainability of the oil and gas industry. These advancements continue to push the boundaries of horizontal drilling, revolutionizing the way hydrocarbons are extracted and unlocking new opportunities for energy production in California and beyond.